Subaru Legacy (2005 year). Manual - part 601

5AT-103

AUTOMATIC TRANSMISSION

AT Main Case

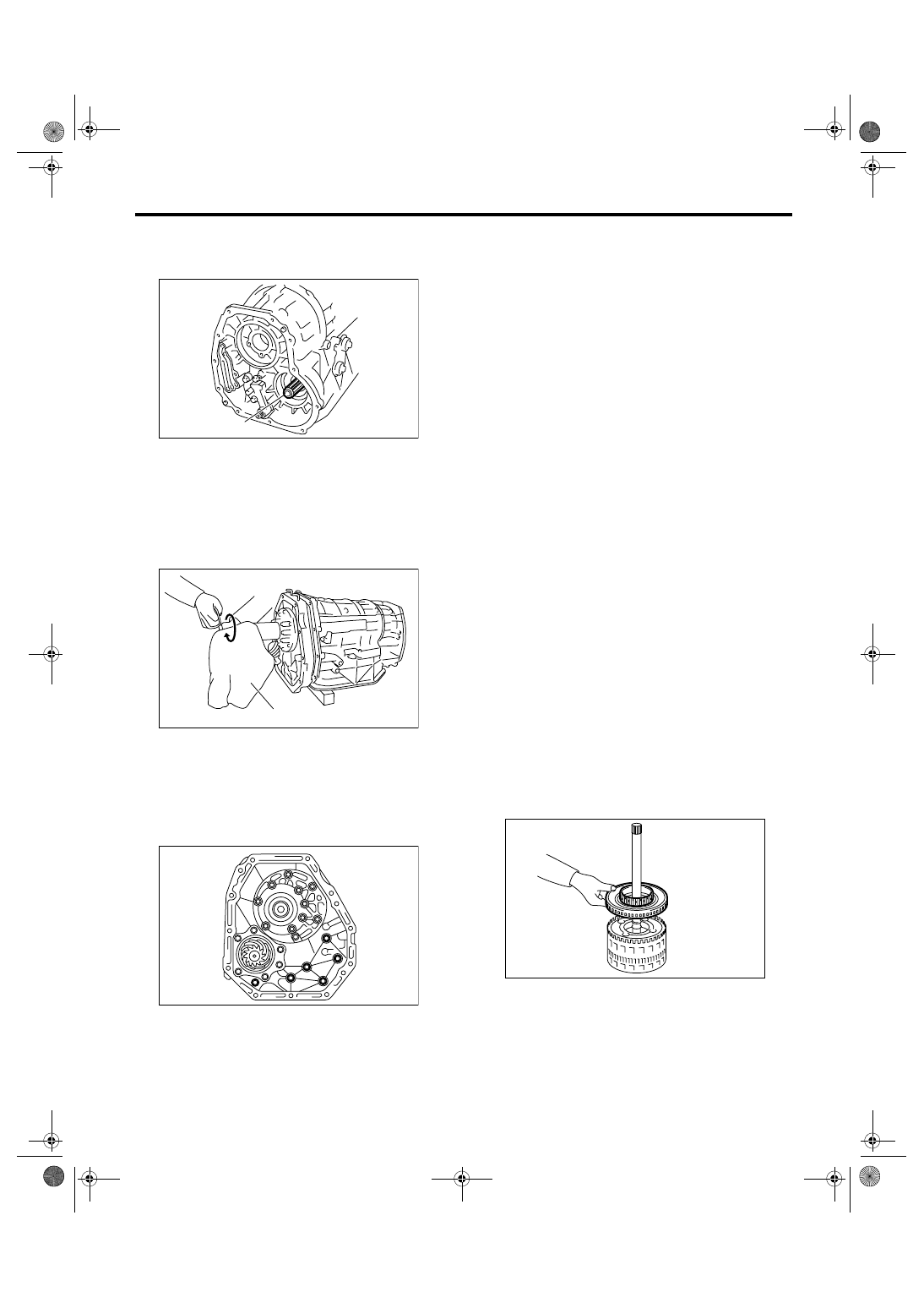

(3) Make sure the rear end of drive pinion shaft

is engaged to the spline of reduction driven

gear.

(4) Protect the input clutch shaft with a cloth,

and rotate to engage the spline of input clutch

and rear carrier using pliers.

NOTE:

Work with pressing the oil pump cover.

(5) Combine the oil pump cover with transmis-

sion main case.

Tightening torque:

41 N

⋅

m (4.2 kgf-m, 30.2 ft-lb)

23) Install the center differential carrier. <Ref. to

5AT-78, INSTALLATION, Center Differential Carri-

er.>

24) Install the reduction driven gear. <Ref. to 5AT-

76, INSTALLATION, Reduction Driven Gear.>

25) Install the extension case and intermediate

case. <Ref. to 5AT-71, INSTALLATION, Extension

Case and Intermediate Case.>

26) Install the control valve body. <Ref. to 5AT-58,

INSTALLATION, Control Valve Body.>

27) Install the converter case assembly into trans-

mission case assembly. <Ref. to 5AT-82, INSTAL-

LATION, Converter Case.>

28) Install the air breather hose. <Ref. to 5AT-68,

INSTALLATION, Air Breather Hose.>

29) Install the ATF filter pipe. <Ref. to 5AT-60, IN-

STALLATION, ATF Filter.>

30) Install the oil charge pipe with a O-ring. <Ref. to

5AT-69, INSTALLATION, Oil Charge Pipe.>

31) Install the torque converter assembly. <Ref. to

5AT-70, INSTALLATION, Torque Converter As-

sembly.>

32) Install the transmission assembly into vehicle.

<Ref. to 5AT-42, INSTALLATION, Automatic

Transmission Assembly.>

33) Perform the Clear Memory 2. <Ref. to 5AT(di-

ag)-19, CLEAR MEMORY MODE, OPERATION,

Subaru Select Monitor.>

34) Perform the inspection with driving the vehicle

at the end of repair work, and make sure there is no

faulty as below;

• Excessive shift shock

• Oil leakage from transmission body and etc.

• Occurrence of noise caused by interference etc.

NOTE:

If excessive shift shock is felt, execute the advance

operation of learning control. <Ref. to 5AT(diag)-

23, PROCEDURE, Learning Control.>

C: DISASSEMBLY

1. INPUT CLUTCH PACK ASSEMBLY

1) Remove the front sun gear.

(A) Drive pinion shaft

(A) Cloth

AT-02092

(A)

AT-02046

(A)

AT-01976

AT-02007