Subaru Legacy (2005 year). Manual - part 486

EN(H6DO)(diag)-257

ENGINE (DIAGNOSTICS)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DB:DTC P2128 THROTTLE/PEDAL POSITION SENSOR/SWITCH “E” CIRCUIT

HIGH INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

• Erroneous idling

• Poor driving performance

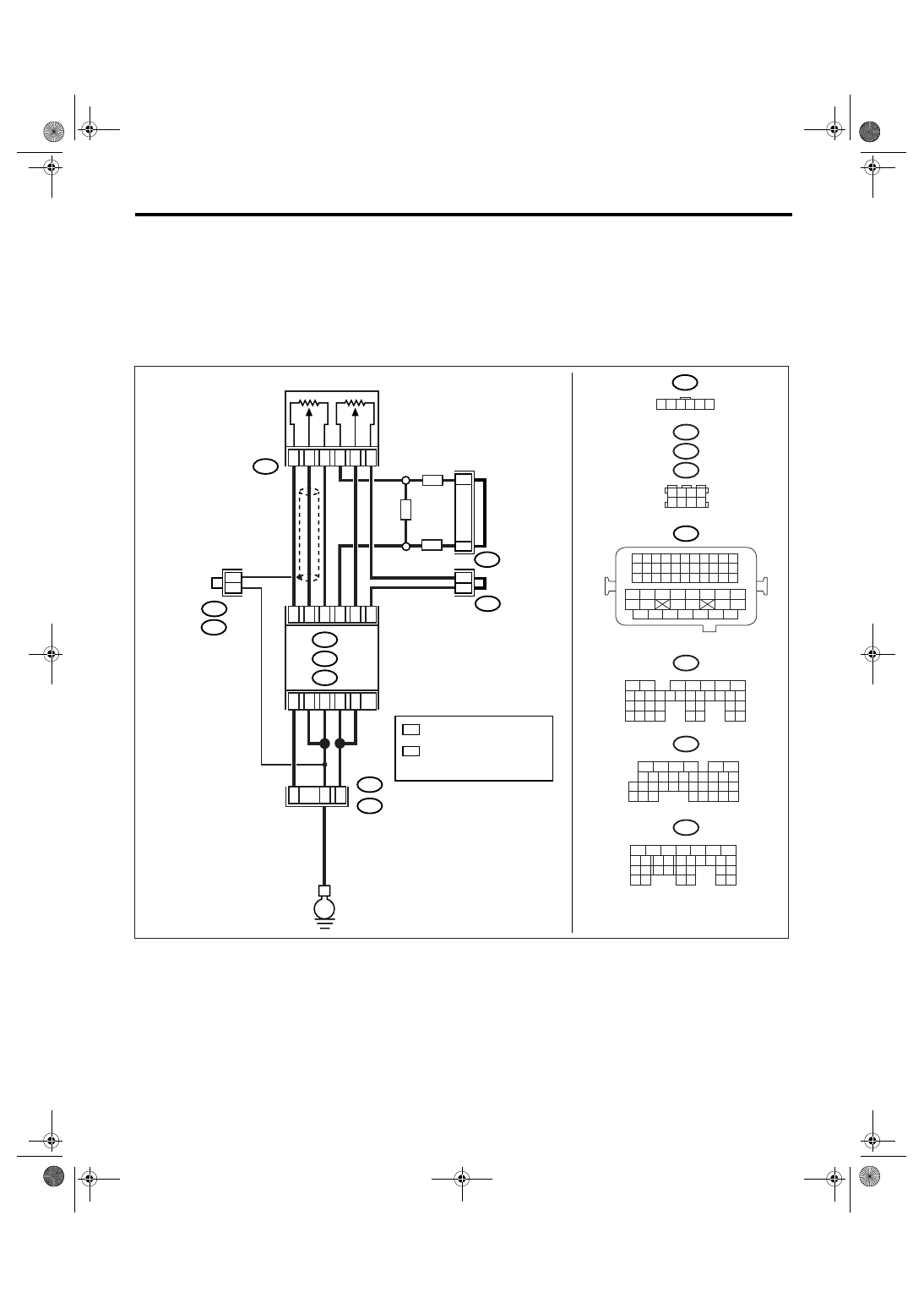

WIRING DIAGRAM:

EN-03506

B315

E

C:

ECM

B136

B137

D:

B83

B315

ACCELERATOR

PEDAL POSITION

SENSOR

*

*

3

5

4

1

2

6

C15

C17

C34

C16

C28

C35

D1

D2

B21

E2

B1

B138

1 2 3 4

5 6 7 8

MAIN

SUB

B21

1 2 3 4

12 13 14 15

5 6 7 8

16 17 18 19

9 10 11

20 21 22

23 24 25 26 27 28 29 30 31 32 33

35

34

37

36

39

38

41

40

43

42

44

45

47

46

49

48

51

50

53

52

54

B137

5

6

7

8

2

1

9

4

3

10

22 23

11 12 13 14 15

24 25

26

16 17

18 19 20 21

27

28 29

30 31

B136

5

6

7 8

2

1

9

4

3

10

24

22 23

25

11 12 13 14 15

26 27

28

16

17 18 19 20 21

33 34

29

32

30

31

35

B135

5

6

7

8

2

1

9

4

3

10

24

22 23

25

11 12 13 14 15

26 27

28

16 17 18 19

20 21

29 30 31

32 33

34 35

B:

C:

D:

B122

B83

B122

D3

B: B135

B4

37

36

35

1 2 3 4 5 6

*

*

1

1

1

*

2

*

2

1

: TERMINAL No.

RANDOM ARRANGEMENT

*

1

LHD

RHD

RHD

*

: TERMINAL No.

RANDOM ARRANGEMENT

AMONG 3,4,7, AND 8

2

B122

B138

: LHD

: RHD