Subaru Legacy (2005 year). Manual - part 336

EN(H4DOTC)(diag)-113

ENGINE (DIAGNOSTICS)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

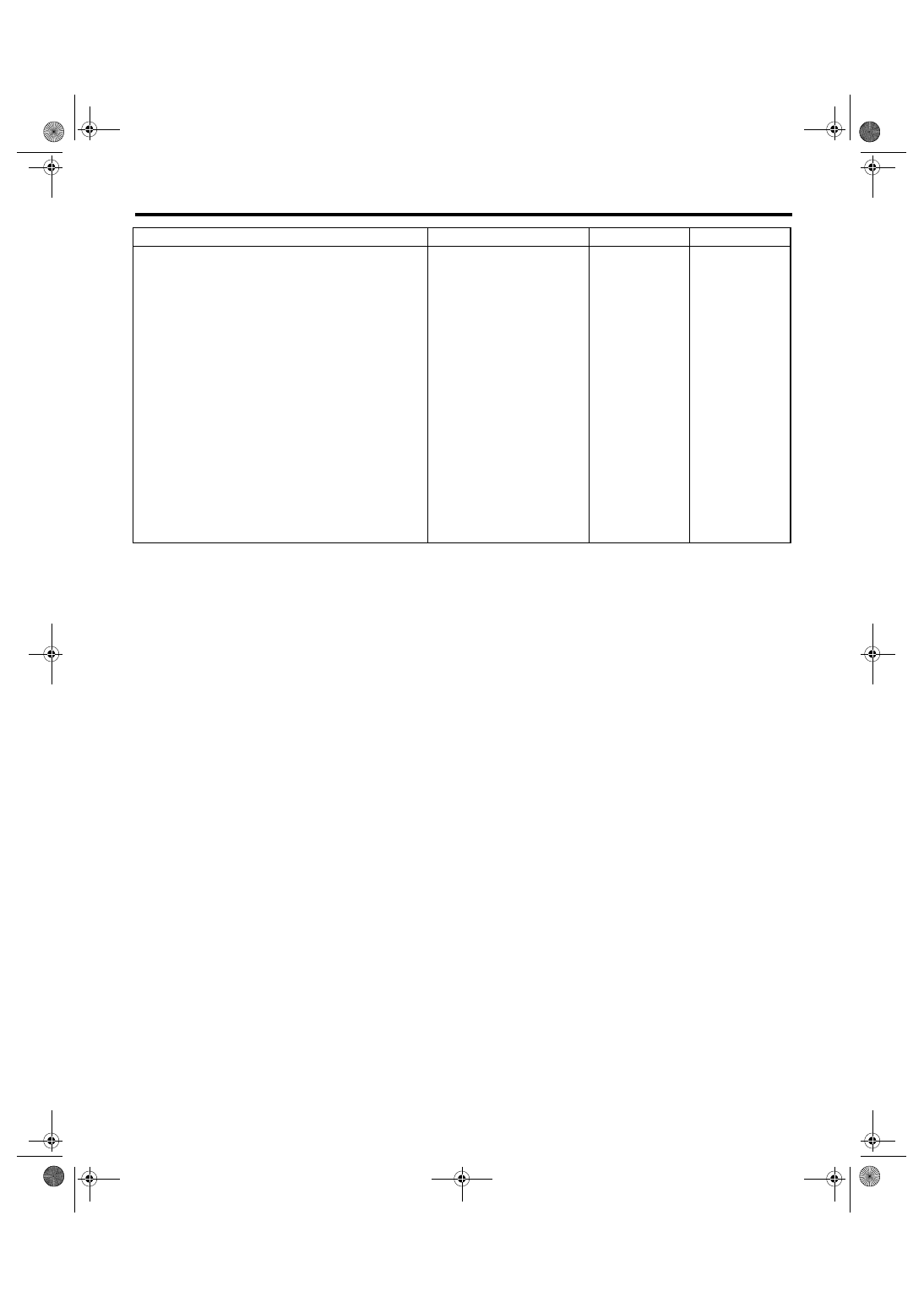

7

CHECK MASS AIR FLOW AND INTAKE AIR

TEMPERATURE SENSOR.

1) Start and warm-up the engine until engine

coolant temperature is above 60

°C (140°F).

2) Place the shift lever in neutral position.

3) Turn the A/C switch to OFF.

4) Turn all the accessory switches to OFF.

5) Open the front hood.

6) Measure the ambient temperature.

7) Read the data of mass air flow and intake

air temperature sensor signal using Subaru

Select Monitor or general scan tool.

NOTE:

• Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA FOR ENGINE”. <Ref.

to EN(H4DOTC)(diag)-24, Subaru Select Mon-

itor.>

• General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Subtract the ambient tempera-

ture from intake air tempera-

ture. Is the value from

−10°C

(14

°F) to 50°C (122°F)?

Replace the ECM.

<Ref. to

FU(H4DOTC)-34,

Engine Control

Module (ECM).>

Check the mass

air flow and intake

air temperature

sensor. <Ref. to

FU(H4DOTC)-27,

Mass Air Flow and

Intake Air Temper-

ature Sensor.>

Step

Check

Yes

No