Subaru Legacy (2005 year). Manual - part 273

ME(H4DOTC)-35

MECHANICAL

Engine Assembly

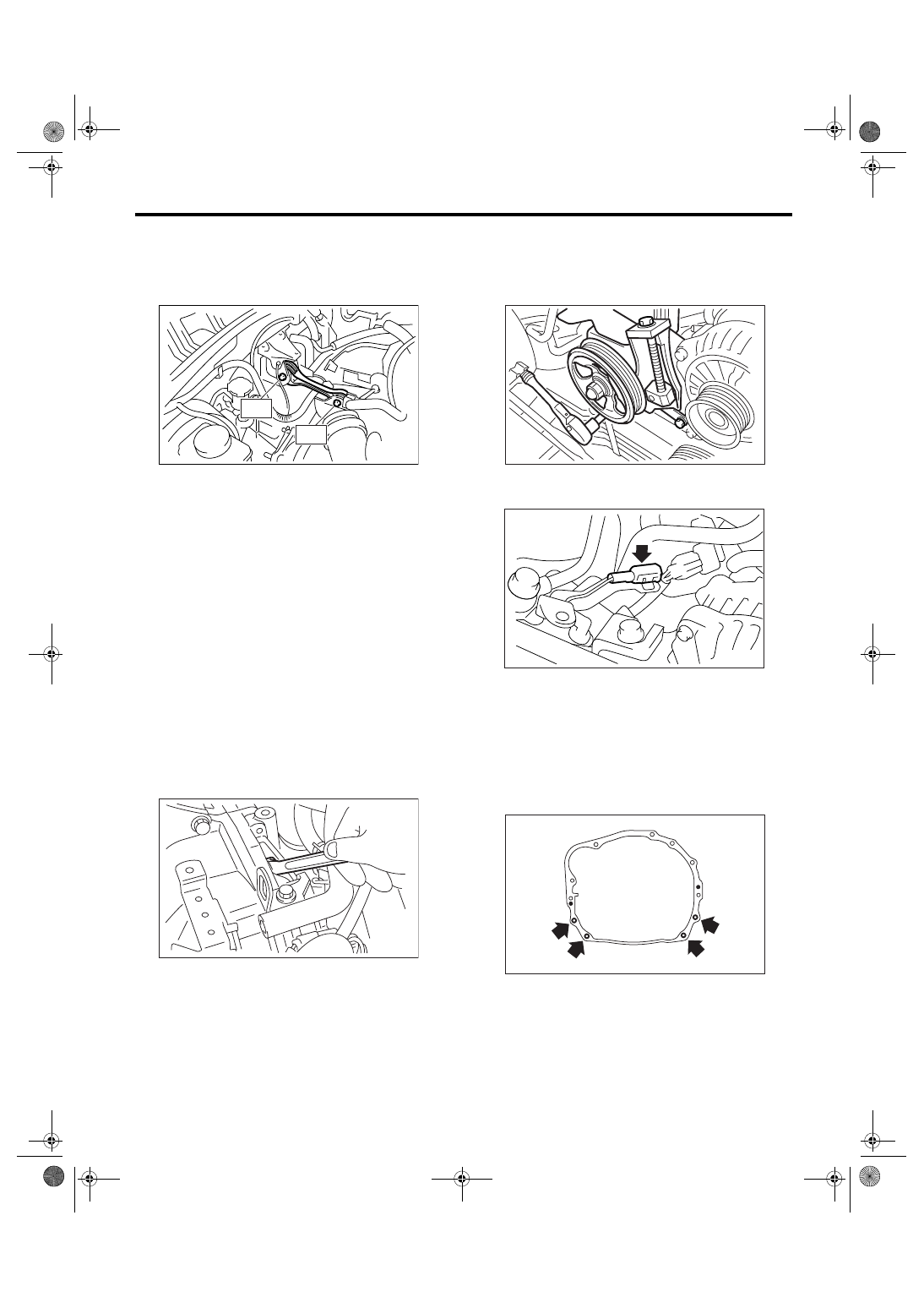

6) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅

m (5.1 kgf-m, 36.9 ft-lb)

T2: 58 N

⋅

m (5.9 kgf-m, 43 ft-lb)

7) Remove the ST from converter case. (AT model)

NOTE:

Be careful not to drop the ST into the converter

case when removing ST.

ST

498277200

STOPPER SET

8) Install the starter. <Ref. to SC(H4SO 2.0)-6, IN-

STALLATION, Starter.>

9) Install the torque converter clutch to drive plate.

(AT model)

(1) Tighten the bolts which hold torque convert-

er clutch to drive plate.

(2) Tighten other bolts while rotating the crank-

shaft by using ST.

CAUTION:

Be careful not to drop bolts into the torque con-

verter clutch housing.

ST

499977400

CRANK PULLEY WRENCH

Tightening torque:

25 N

⋅

m (2.5 kgf-m, 18.4 ft-lb)

10) Install the linear motion mounting. <Ref. to

ME(H4DOTC)-38, INSTALLATION, Linear Motion

Mounting.>

11) Install the power steering pump on bracket.

(1) Install the power steering pump.

Tightening torque:

20.1 N

⋅

m (2.05 kgf-m, 14.8 ft-lb)

(2) Connect the power steering switch connec-

tor.

12) Lift-up the vehicle.

13) Tighten the nuts which hold lower side of the

transmission to engine.

Tightening torque:

50 N

⋅

m (5.1 kgf-m, 36.9 ft-lb)

LU-00224

T2

T1

ME-00044

ME-00037

ME-00035

ME-00040