Subaru Legacy (2005 year). Manual - part 71

ME(H4SO 2.0)-67

MECHANICAL

Cylinder Block

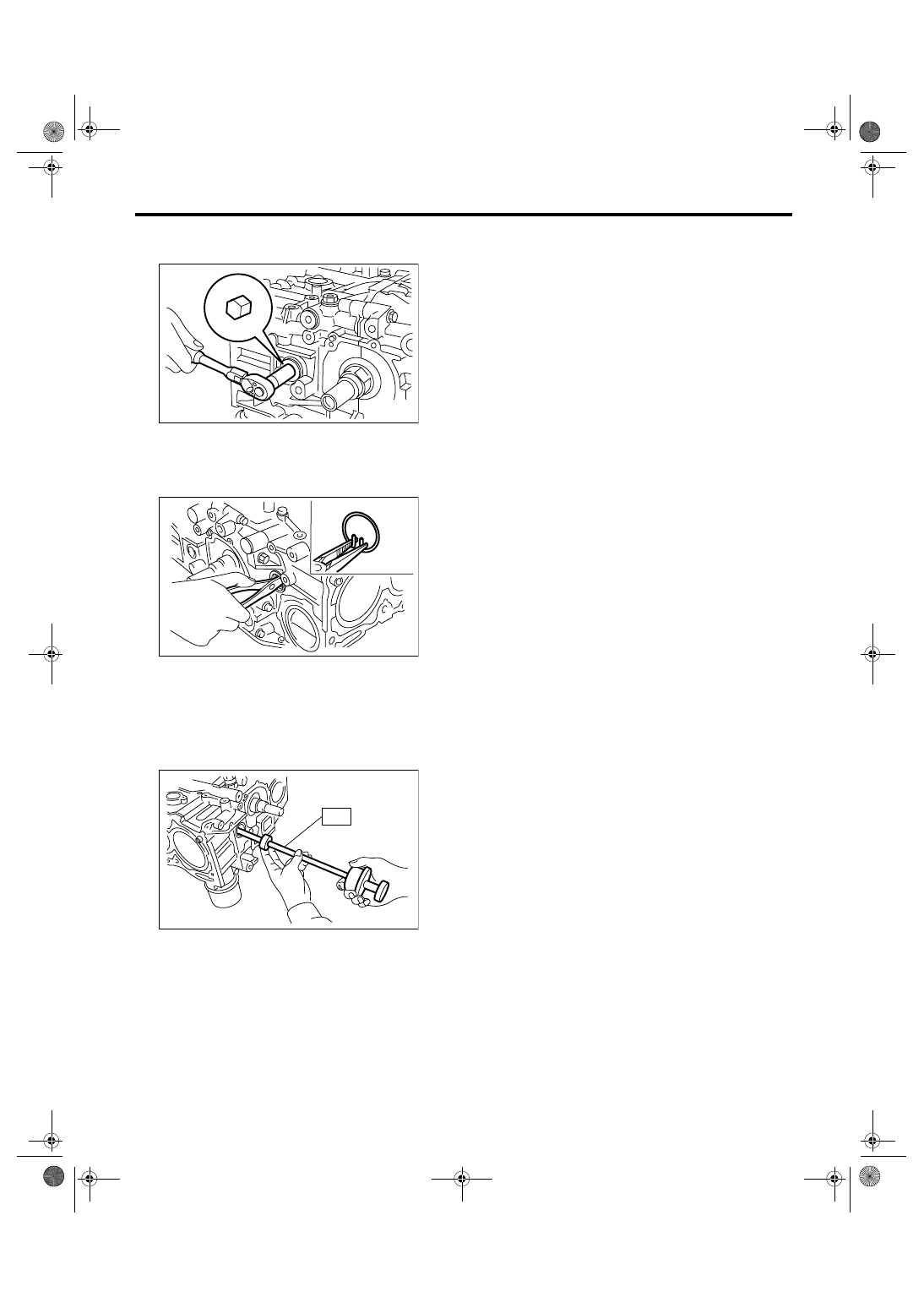

28) Remove the service hole cover and service

hole plugs using a hexagon wrench (14 mm).

29) Rotate the crankshaft to bring #1 and #2 pis-

tons to bottom dead center position, then remove

the piston snap ring through service hole of #1 and

#2 cylinders.

30) Draw out the piston pin from #1 and #2 pistons

using ST.

ST

499097700

PISTON PIN REMOVER

NOTE:

Be careful not to confuse the original combination

of piston, piston pin and cylinder.

31) Similarly remove the piston pins from #3 and #4

pistons.

32) Remove the bolts which connect cylinder block

on the side of #2 and #4 cylinders.

33) Loosen the bolts which connect cylinder block

on the side of #1 and #3 cylinders for two or three

turns.

34) Set up the cylinder block so that #1 and #3 cyl-

inders are on the upper side, then remove the cyl-

inder block connecting bolts.

ME-00140

ME-00141

ME-00142

ST