SsangYong Rexton. Manual - part 609

SSANGYONG Y200

5D2-84 TRANSFER CASE - TOD

YAD5D650

YAD5D660

YAD5D670

YAD5D680

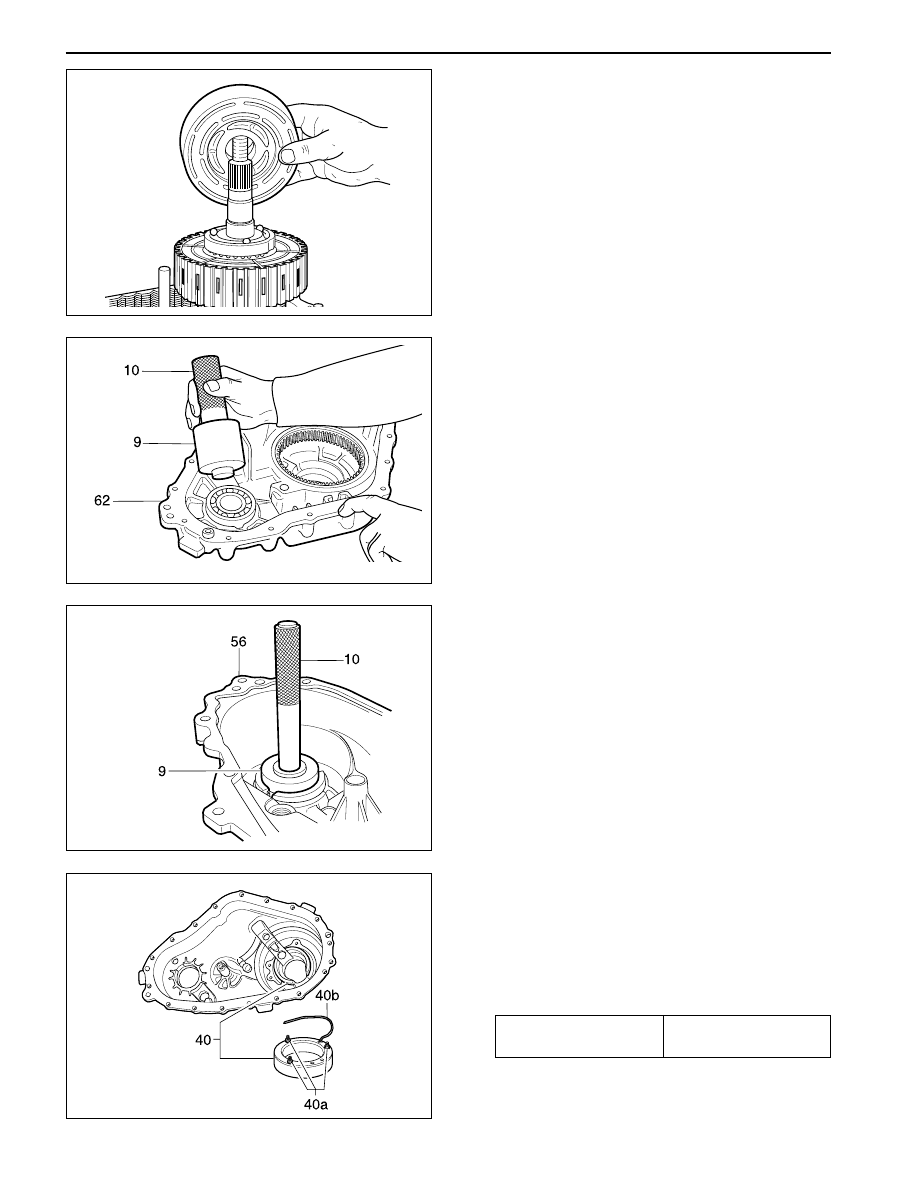

28. Install apply cam onto the rear output shaft,

29. Install three balls into the apply cam.

30. Install cam and coil housing assembly onto rear

output shaft.

31. Install thrust bearing assembly onto output shaft.

35. Install the clutch coil from inside the rear case until

the wire and studs extend through the cover.

Notice: Do not kink or trap the wire while seating

the clutch coil to the case.

36. Install the washers and nuts and tighten.

Installation Notice

33. If removed, install the rear output bearing in the

rear case bore. Drive the bearing into the rear

case bore with Output Shaft Bearing Replacer and

Driver Handle. Make sure that the bearing is not

cocked in the bore.

34. Install the internal snap ring that retains the bearing

to the rear case.

32. If removed, drive the front output shaft ball bearing

into the rear cover bore with Front Shaft Needle

Bearing Replacer and Driver Handle.

Tightening Torque

8 - 11 N•m

(71 - 97 lb-in)