SsangYong Rexton. Manual - part 608

SSANGYONG Y200

5D2-80 TRANSFER CASE - TOD

44. If required, remove the front yoke to flange seal

by prying and pulling on the curved-up lip of the

yoke to flange seal.

Notice: Be careful not to damage the bearing,

bearing cage or case.

45. If required, remove the internal snap ring retaining

the front output shaft ball bearing and remove the

bearing.

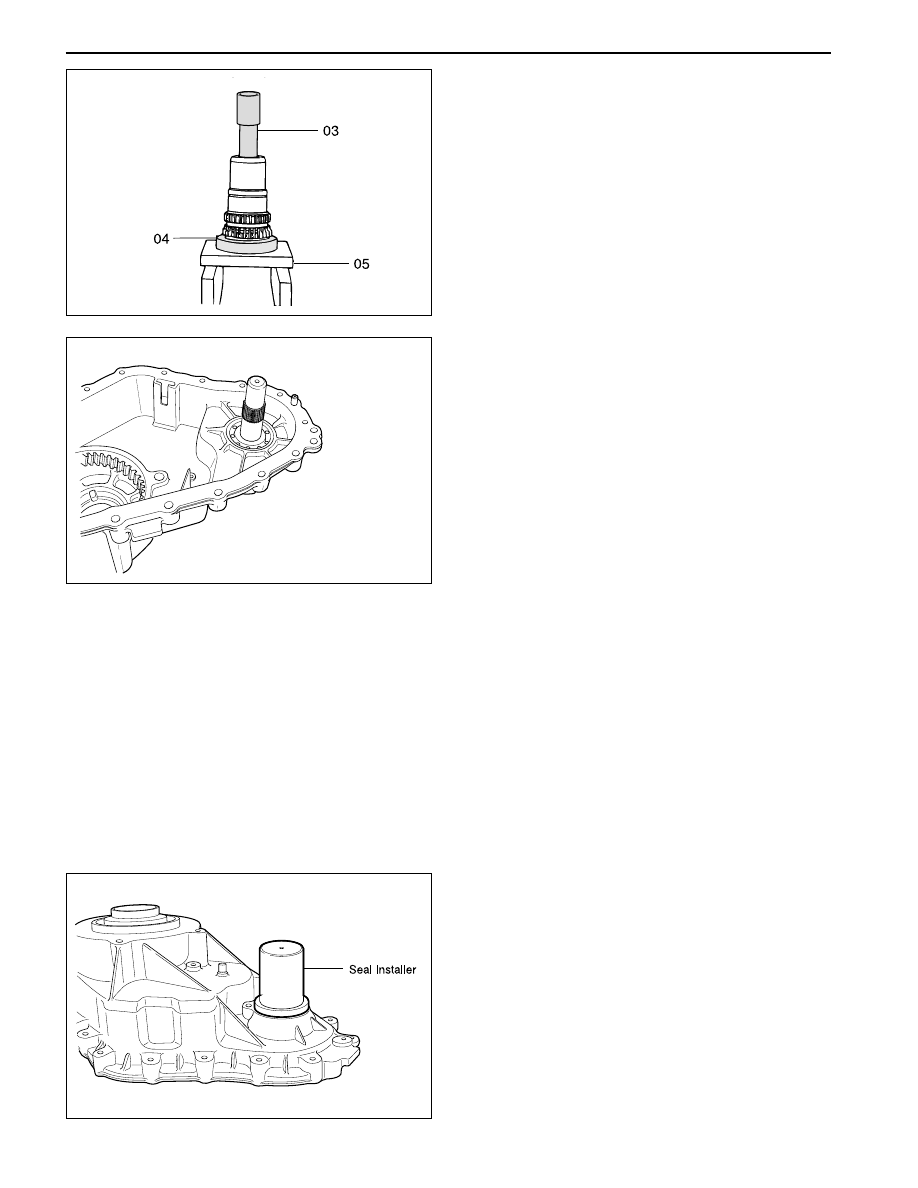

43. If replacement of the needle bearing and bushing

is required, press the bearing and bushing is

required, press the bearing and bushing out as

follows:

•

Position the input shaft on Axle Bearing/Seal

plate, and using Pinion Bearing Cone Replacer

as a spacer.

•

Insert Input Shaft Bearing Remover into the input

shaft so it is resting on top of the bearing cage.

•

Tighten the actuator pin until it stops, then press

the bearing and bushing out together.

YAD5D500

YAD5D510

Assembly Procedure

1. Before assembly, lubricate all parts with Automatic

Transmission Fluid or equivalent.

2. If removed, drive the bearing into the front output

case bore.

Notice: Drive the bearing in straight, making sure

it is not cocked in the bore.

3. Install the internal snap ring that retains the bearing

to the front case.

4. If removed, install the front yoke to flange seal in

the front case bore.

5. If removed, install the yoke to flange seal into the

mounting adapter bore.

YAD5D520