SsangYong Rexton. Manual - part 449

SSANGYONG Y200

1F3-16 DIESEL ENGINE CONTROLS

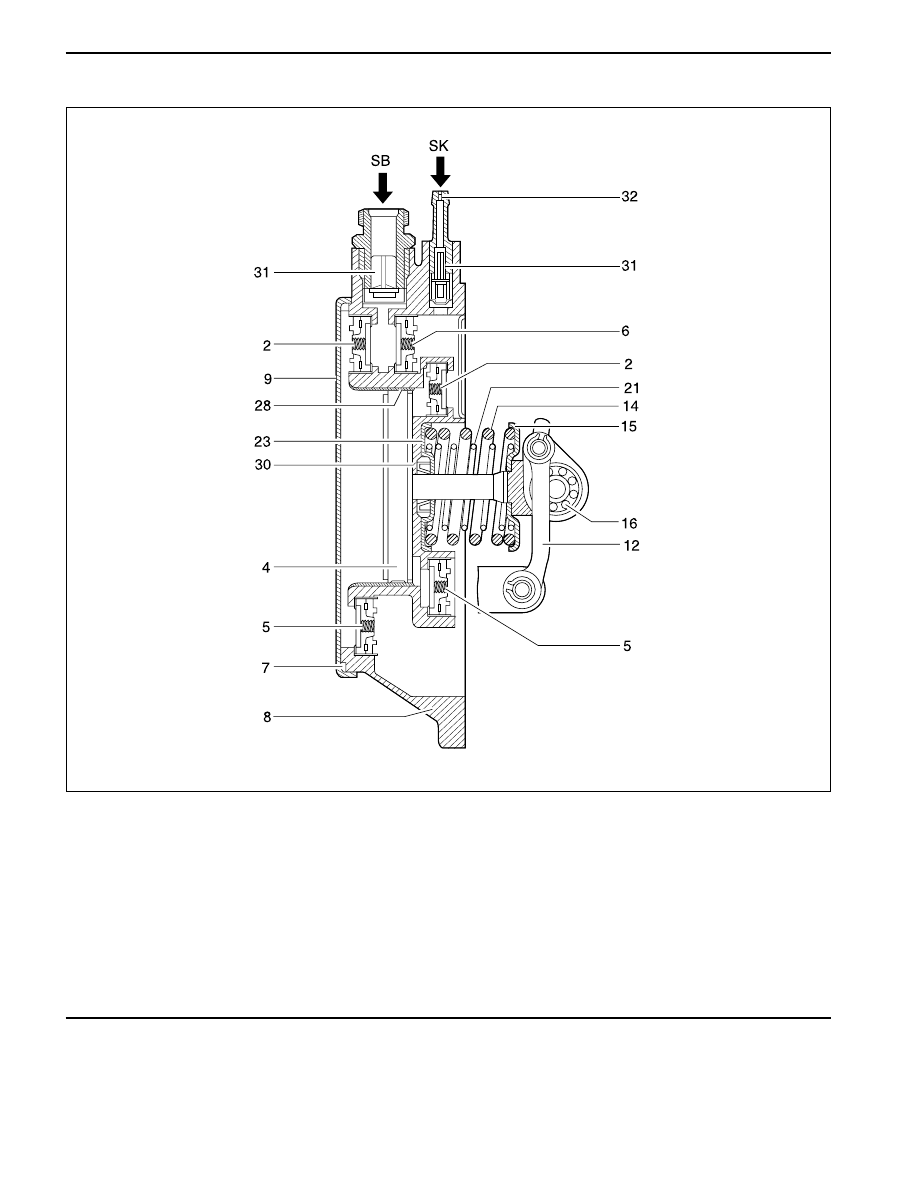

VACUUM PUMP (SECTIONAL VIEW)

2 Suction Valve

4 Piston

5 Pressure Valve

6 Safety Valve

7 O-Ring

8 Pump Housing

9 Pump Cover

12 Lever

14 Outer Return Spring

15 Inner Spring Retainer

16 Roller Cam

17 Piston Rod

21 Inner Return Spring

23 Upper Spring Retainer

28 Piston Ring

30 Seal Ring

31 Oil Return Valve

32 Restrictor

SB To Brake Booster

SK To Vacuum Lines

YAD1FAP0