SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 90

DI02-35

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE HOUSING

DI ENG SM - 2004.9

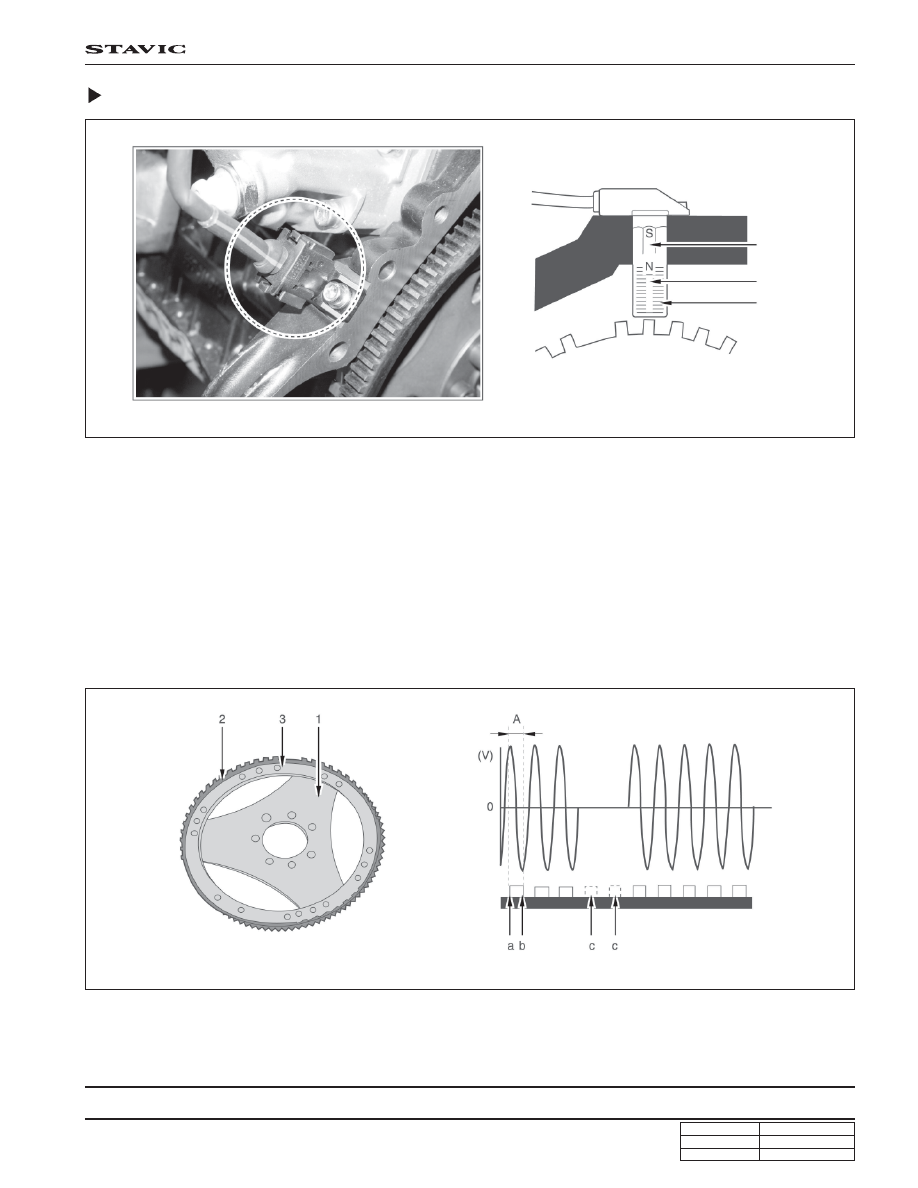

Crankshaft Position Sensor

The crankshaft position sensor is located near to flywheel on the rear of cylinder block. It generates AC voltage between

increment type driven plate that fixed on flywheel inside. The sensor consists of soft iron core that winded copper wire

on permanent magnet and generates sign wave AC voltage when magnetism on the sensor wheel passes the sensor.

When the crankshaft rotates, ‘+’ signal will be generated from near the front edge and ‘-’ signal will be generated from

near the rear edge among teeth on the driven plate near to crankshaft position. The AC voltage increases as the engine

speed increases, however, no signal occurs from the 2-missing-tooth on the increment type driven plate. By using these

teeth, ECU recognizes TDC of No. 1 and 5 cylinders.

ECU converts the alternative signals into digital signals to recognize crankshaft position, piston position and engine

speed. The piston position that coupled with crankshaft is main factor in calculating injection timing. By analyzing the

reference position and camshaft position sensor, can recognize No. 1 cylinder and calculate the crankshaft speed.

A. Distance between ‘+’ max. voltage and ‘-’ max.

voltage

a. Front edge

b. Rear edge

c . 2-missing-tooth

<Location of crankshaft position sensor>

<Drive plate>

<Structure of crankshaft position sensor>

Permanent

magnet

Ring gear

Iron

coil

Standard

position