SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 79

DI01-11

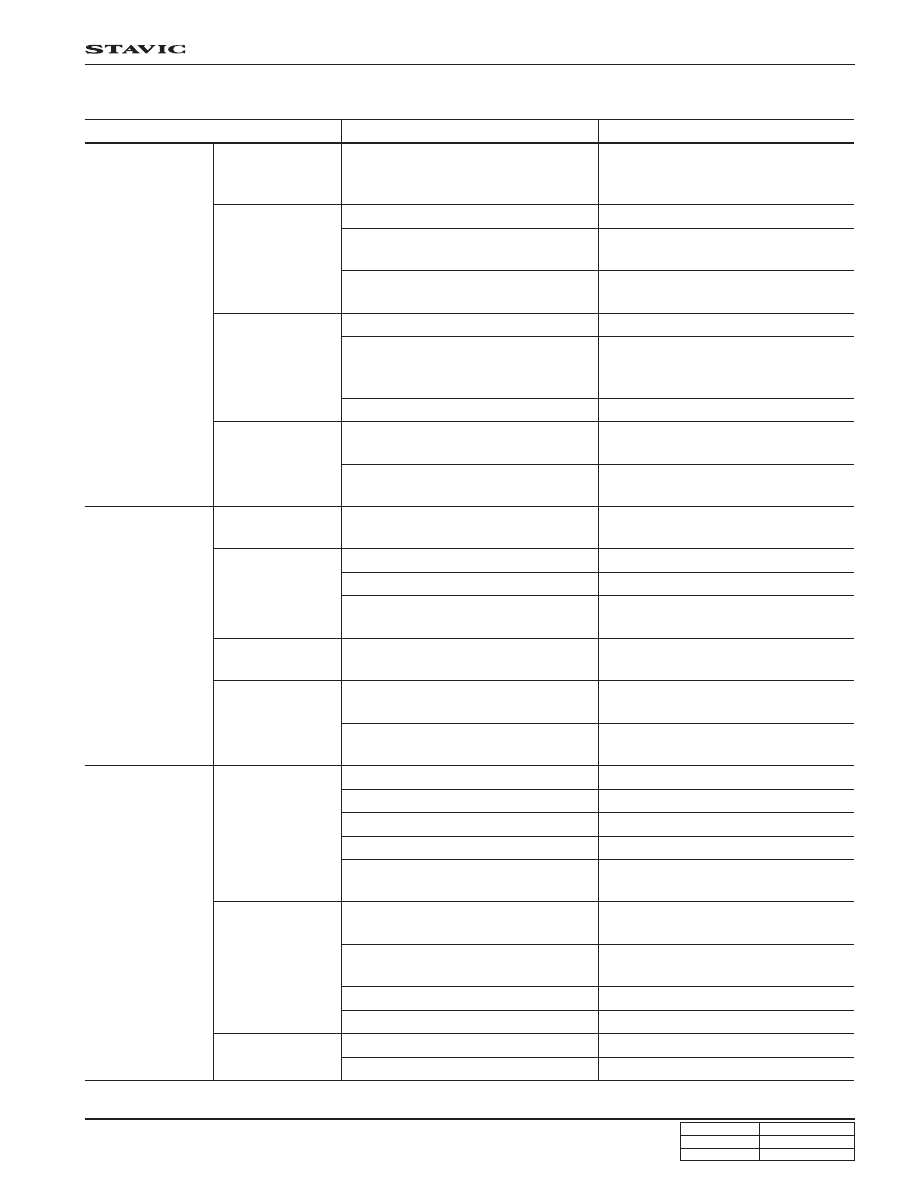

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE ASSEMBLY

DI ENG SM - 2004.9

Probable Cause

• Refer to “Compression Pressure

Test”.

• Clogged fuel pipe.

• Clogged or contaminated fuel

filter.

• Malfunction of the fuel pressure

regulator.

• Malfunction of the spark plug.

• Electric leakage or poor

connection of the high tension

cable.

• Poor ignition timing.

• Leak of the intake manifold

gasket.

• Leakage of the vacuum hose.

• Refer to “Overheat” in this page.

• Abnormal spark plug.

• Poor ignition timing.

• Electric leakage or poor connec-

tion of the high tension cable.

• Clogged or contaminated fuel

filter and fuel pipe.

• Leak of the intake manifold

gasket.

• Excessive carbon deposit due to

abnormal combustion.

• Lack of coolant.

• Malfunction of the thermostat.

• Malfunction of the cooling fan.

• Poor water pump performance.

• Clogged or leaky radiator.

• Poor engine oil.

• Blocking oil filter or strainer.

• Lack of engine oil.

• Poor oil pump performance.

• Leakage of oil

• Damaged cylinder head gasket.

Correction

• Refer to “Compression Pressure

Test”.

• Clean the pipe.

• Replace the filter.

• Replace the fuel pressure

regulator.

• Adjust or replace the spark plug.

• Connect the cable correctly or

replace it.

• Adjust the ignition timing.

• Clean or replace the gasket.

• Connect the hose correctly or

replace it.

• Refer to “Overheat” in this page.

• Replace the spark plug.

• Adjust the ignition timing

• Connect the cable correctly or

replace it.

• Clean or replace the fuel filter and

the fuel pipe.

• Replace the gasket.

• Remove the carbon.

• Refill coolant.

• Replace the thermostat.

• Check or replace the cooling fan.

• Replace the pump.

• Clean, repair or replace the

radiator.

• Replace engine oil with the

specified one.

• Clean or repair the oil filter or the

strainer.

• Refill oil.

• Replace or repair the pump.

• Repair.

• Replace the gasket.

Condition

GENERAL DIAGNOSIS (Cont’d)

Decline of

Compression

Pressure

Engine Surging

(Engine power

makes

fluctuation in a

fixed speed and

speed changes

without

operating the

accelerating

pedal.)

Malfunction of

Fuel System

Overheat

Malfunction of

Ignition System

Others

Others

Malfunction of

Fuel System

Malfunction of

Cooling System

Excessive

Detonation

(According to

the opening

range of Mal-

function of

metallic is made

with abnormal

explosion )

Malfunction of

Ignition System

Malfunction of

Lubrication

System

Other

Overheated

Engine