SsangYong Musso. Manual - part 522

TRANSFER CASE (TOD) 5D2-35

Removal & Installation Procedure

1. Disconnect (-) cable from battery.

2. Lift on vehicle and make sure on safety.

Notice

Be careful for catalytic converter due to high temperature

after driving or engine running.

3. Prepare a vessel to drain transfer case and manual

transmission oil.

4. Release drain plug and drain transfer case and manual

transmission oil.

If planar damper is installed, unscrew 4 bolts and remove

the planar damper.

Notice

Oil drain should be along with whole transfer case

disassembly and assembly.

5. Disconnect transmission extension wiring connector back

side transfer case.

Notice

When disconnect connector, make sure on direction of

locking tab towards inside.

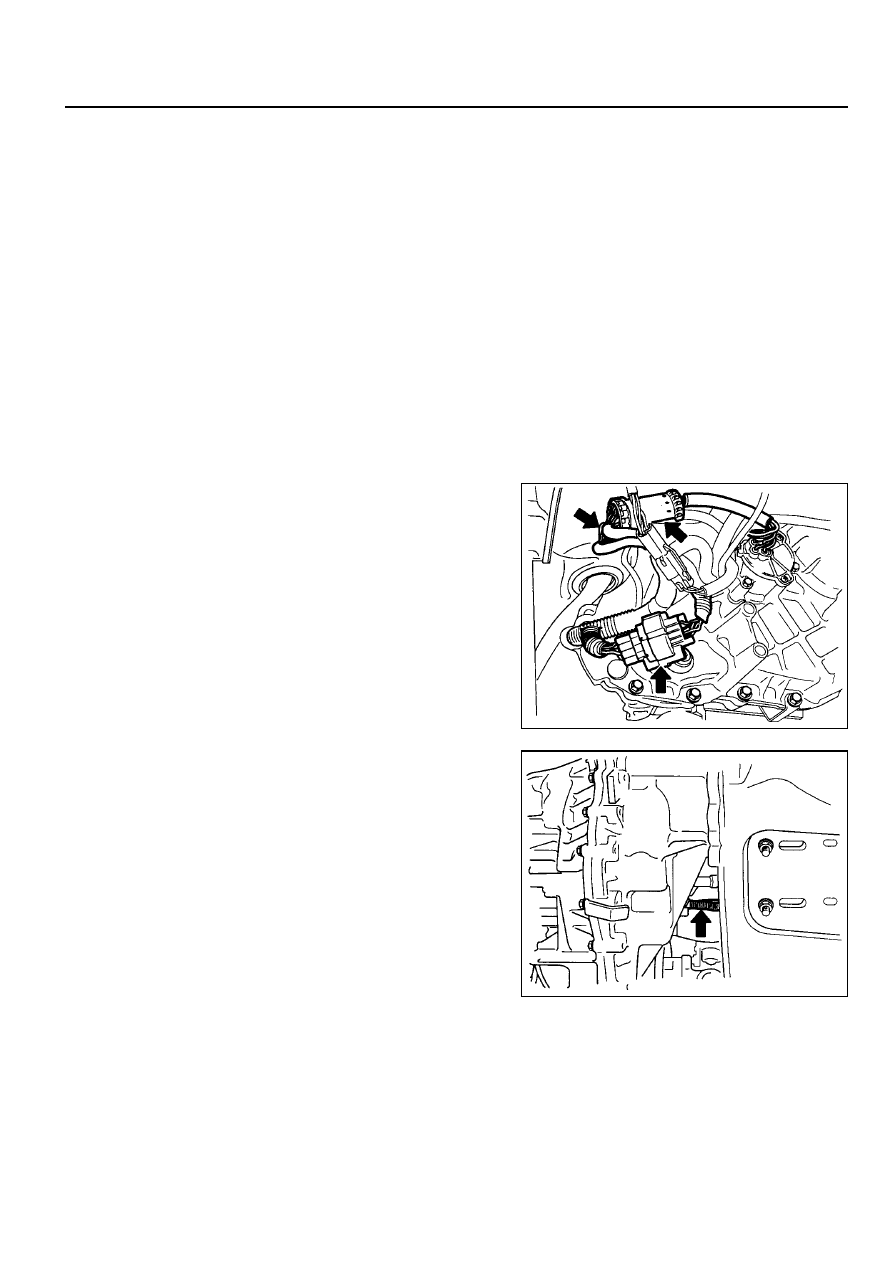

6. Disconnect shift motor/clutch coil connect (Black 7 pin)

connector upper backside.

7. Disconnect front and rear speed sensor connector (white

7 pin).

8. Disconnect speedometer sensor connector right upper

side.

9. Disconnect breather tube front upper side transfer case

(upper connecting point of transfer case and front

propeller).

10. Prepare hydraulic jack and support transfer case assembly.