SsangYong Musso. Manual - part 483

AUTOMATIC TRANSMISSION 5A-109

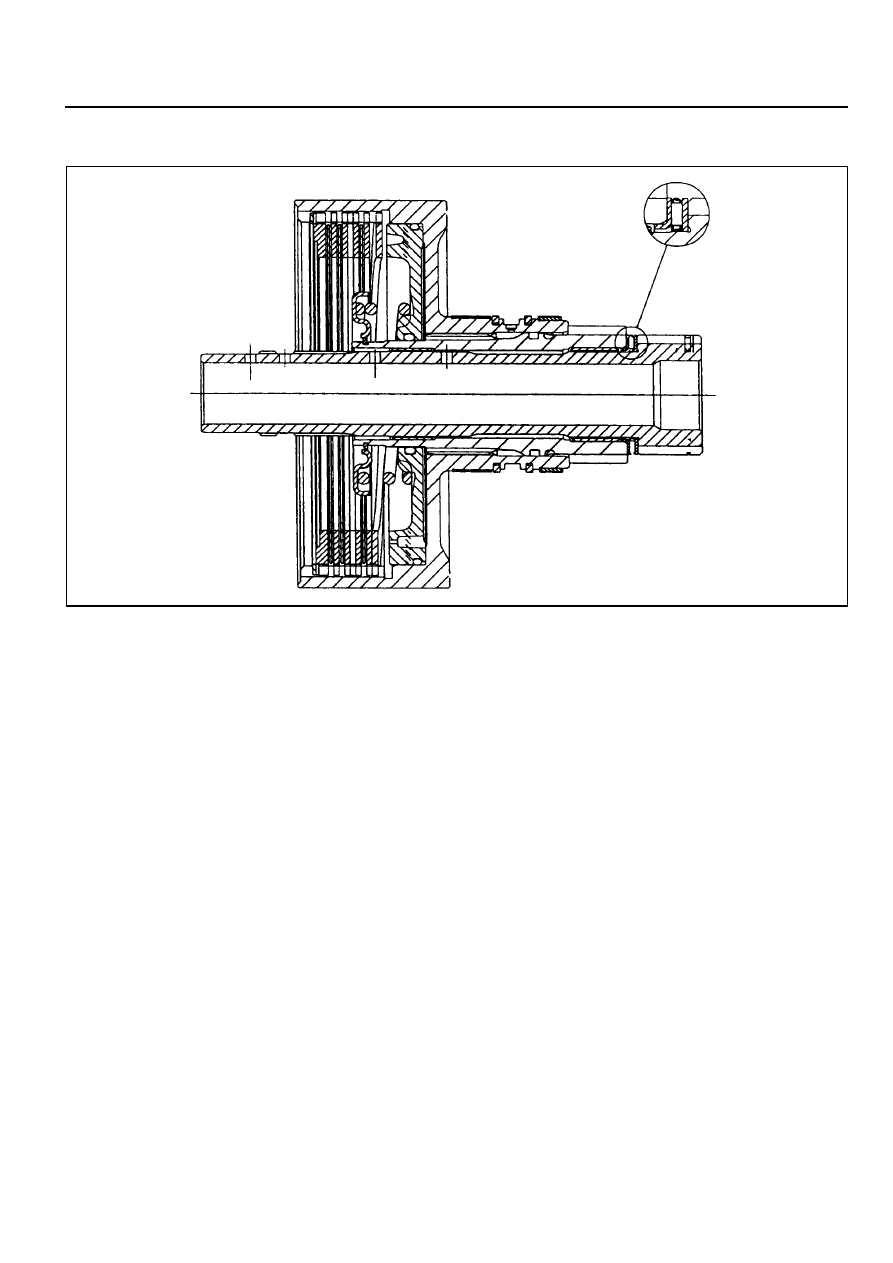

Forward Sun Gear and C3 Clutch Pack Assembly

To assemble the forward sun gear and C3 clutch pack assembly

(Refer to figure 8.30), proceed as follows:

1. Fit the No. 7 needle thrust bearing assembly over the forward

sun gear, ensuring that the thrust washer is between the

bearing and the sun gear.

2. Lubricate the thrust plate with petroleum jelly and fit the

thrust plate onto the reverse sun gear.

Refer to figure 8.33.

3. Align and fit the C3 clutch assembly over the forward sun

gear.

4. Lubricate the No. 6 needle thrust bearing with petroleum

jelly and fit it to the thrust plate. Ensure the lugs on the

outside diameter of the bearing fit in the thrust plate

counterbore.

Refer to figure 8.19.

5. Align and fit the plastic thrust washer to the thrust plate with

petroleum jelly.

Refer to to figures 8.19.

6. Install the assembly over the forward sun gear shaft against

the No.6 thrust bearing.

Refer to figure 8.19.

7. Place the assembly to one side.

Figure 8.30 - Typical forward Sun Gear add C3 Clutch Assembly