SsangYong Musso. Manual - part 471

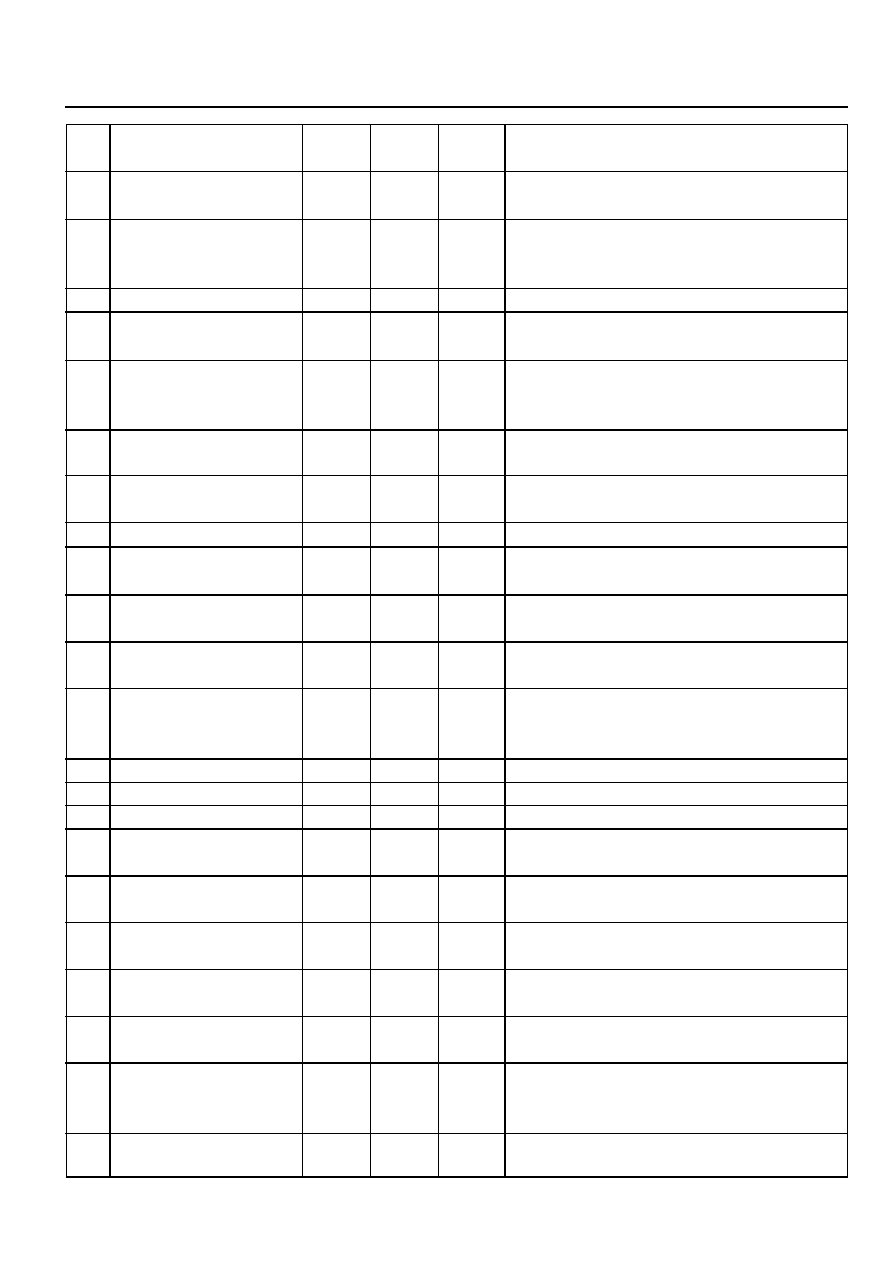

AUTOMATIC TRANSMISSION 5A-61

Pin

No.

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Identification

Mode Indicator Lamp -

‘Power’

Throttle Position Sensor

Output as Pulse Width

Modulation for TOD

Air Conditioner Input Signal

Kickdown Switch

Mode Switch

Transfer Case Input

(High) -4WD Lamp High

Ignition Switch

Do not use

Gear Position ‘1’ Lamp/

Gear Position Code 1

*Gear Position ‘2’ Lamp/

Gear Position Code 2*

Gear Position ‘3’ Lamp/

Gear Position Code 3*

Gear Position ‘Drive’

Lamp/

Gear Position Code 4*

CAN (-ve)

CAN (+ve)

K-line Communication Link

Engine Speed Input

Sensor (+ve)

Road Speed Pulses

Shaft Speed Sensor

Signal

Throttle Position Sensor -

Ground

Throttle Position Sensor -

Reference

Throttle Position Sensor -

Input Signal

Transfer(or Case Input

(Low) - 4WD Lamp Low

Type

OP

OP

-

IP

IP

IP

IP

-

OP

OP

OP

OP

I/O

I/O

I/O

IP

OP

IP

GND

REF

IP

IP

Description

Indicates ‘POWER’ mode shift schedule is se-

lected.

Provides an analogue signal of the throttle po-

sition for the Torque on Demand (TOD) Con-

trol Module.

Input

Switch to indicate when a kickdown is required

at high throttle position.

Switch to select ‘NORMAL’, ‘POWER’ or ‘WIN-

TER’ shift schedule.

Voltage varies from OV to 12V.

Switch to indicate 4WD’HIGH RANGE’ is se-

lected.

Ignition power is used as the main power source

to drive the unit and the solenoids.

Drives jewel in the instrument cluster to indi-

cate

gear leverposition’1'. Drives jewel in the instru-

ment cluster to indicate

gear lever position’2'. Drives jewel in the instru-

ment cluster to indicate gear lever position’3'.

Drives jewel in the instrument cluster to indi-

cate

‘DRIVE’. gear lever position.

CAN low side bus communication (CANL).

CAN high side bus communication (CANH).

Diagnostic information and vehicle coding.

Flywheel/Ring gear pulses to indicate engine

speed.

Road speed signals derived from shaft speed

sensors.

This sensor transmit shaft speed signal to the

TCU.

Throttle position sensor ground.

This is the 5V reference voltage supply gener-

ated by the unit for the throttle position sensor.

This sensor is a resistance potentiometer indi-

cating throttle position.

Voltage varies 0V to 5V.

Switch to indicate 4WD’LOW RANGE’ is se-

lected.

4WD

(Diesel)

O

O

O

O

!

!

!

4WD

(Gas)

O

O

O

O

O

O

O

O

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!