SsangYong Musso. Manual - part 419

1F3-26 OM600 ENGINE CONTROLS

Tools Required

001 589 65 09 00 Serration Wrench

Removal & Installation Procedure

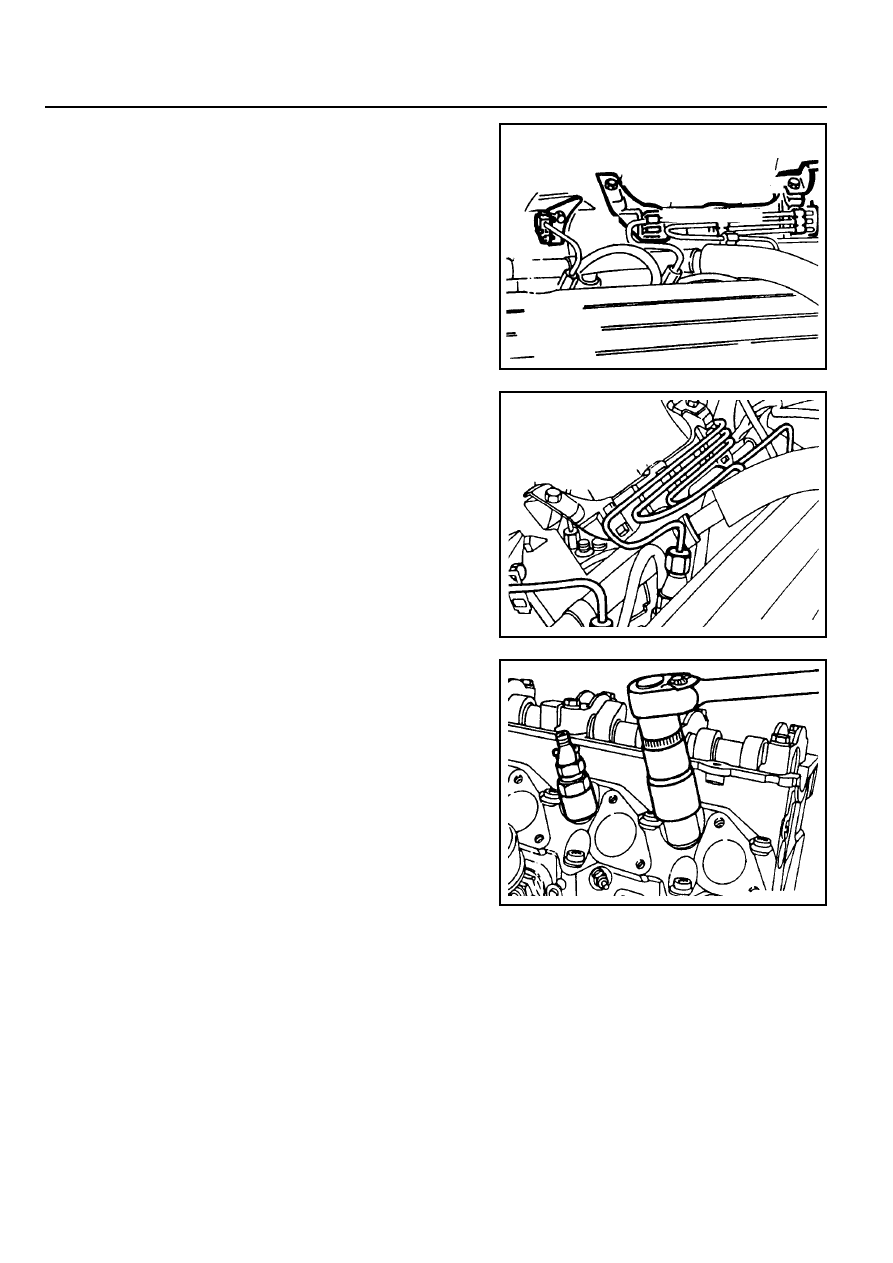

1. Remove the plastic clip from the injection pipe

2. Remove the fuel return hose.

3. Disconnect the injection pipes from the injection nozzles and

push them to the side.

4. Remove the fuel injection nozzle.

Serration Wrench 001 589 65 09 00

Notice

Replace the washers.

5. Installation should follow the removal procedure in the

reverse order.

Notice

Pay attention to the installation position of new nozzle washer

and tightening torque