SsangYong Musso. Manual - part 211

1F-428 ENGINE CONTROLS

SSANGYONG Y158

KAA1F760

KAA1F750

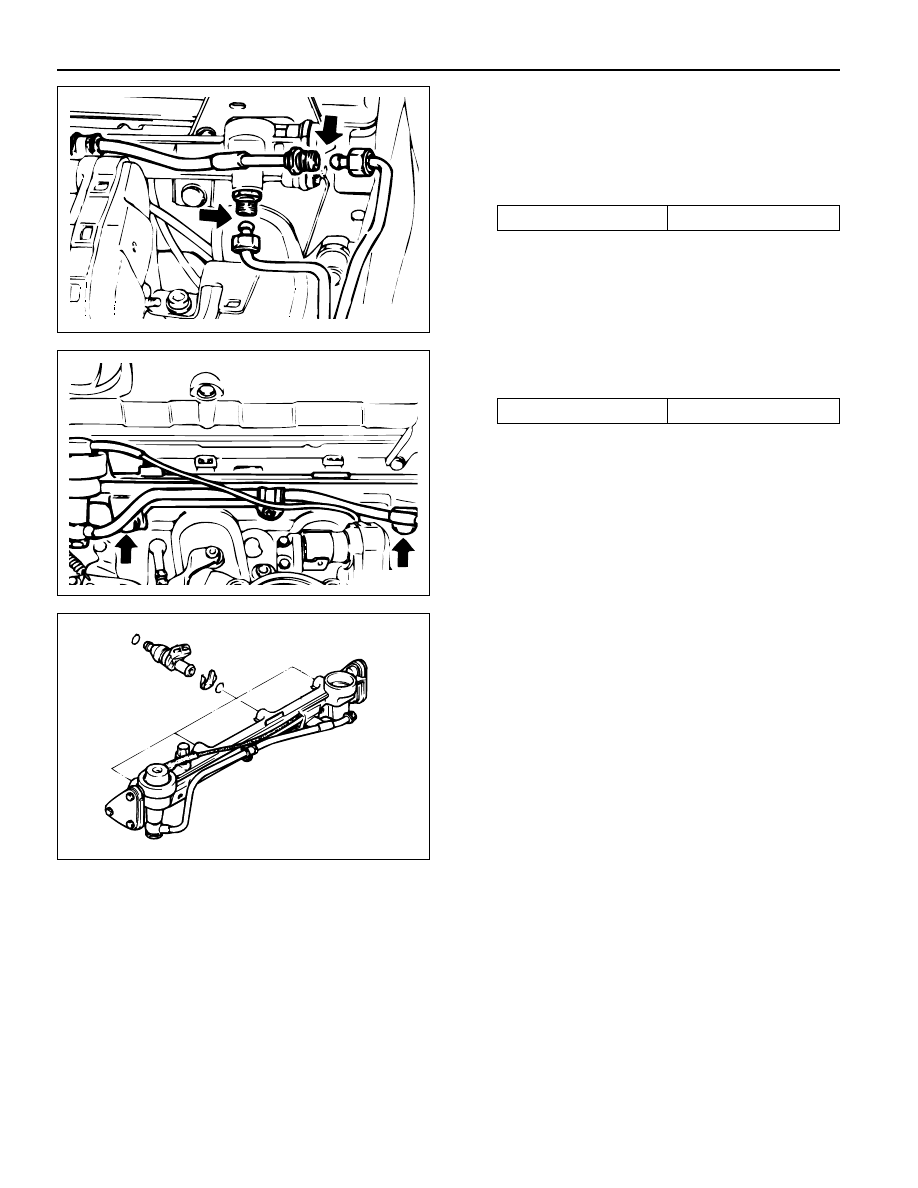

7. Remove the fuel return and supply line.

Notice: For removal, cover around parts with cloths not to

be stained by fuel. In case of checking the injector only,

do not remove the fuel return and supply line.

Installation Notice

8. Remove the for injector connectors.

Notice: Before removal, the fuel rail assembly may be

cleaned with a spray-type cleaner, following package

instructions. Do not immerse the fuel rails in liquid cleaning

solvent. Use care in removing the fuel rail assembly to

prevent damage to the electrical connectors and injector

spray tips. Prevent dire and other contaminants from

entering open lines and passages. Fittings should be

capped and holes plugged during service

Important: If an injection becomes separated from the

rail and remains the cylinder head, replace the injector O-

ring seals and the retaining clip.

10. Remove the injectors and the fuel rail carefully.

11. Remove the fuel injector retainer clips.

12. Remove the fuel injectors by pulling them down and

out.

13. Discard the fuel injector O-rings.

14. Lubricate the new fuel injector O-ring with engine

oil. Install the new O-ring on the fuel injectors.

15. Perform a leak check of the fuel rail and fuel

injectors.

16. Installation should follow the removal procedure in

the reverse order.

9. Remove the two combination bolts.

Installation Notice

Tightening Torque

25 N•m (18 lb-ft)

Tightening Torque

25 N•m (18 lb-ft)

KAA1F750

KAA1F760

KAA1F770