SsangYong Musso. Manual - part 209

1F-420 ENGINE CONTROLS

SSANGYONG Y158

DIAGNOSTIC TROUBLE CODE (DTC) P1813

CLUTCH SWITCH PLAUSIBILITY

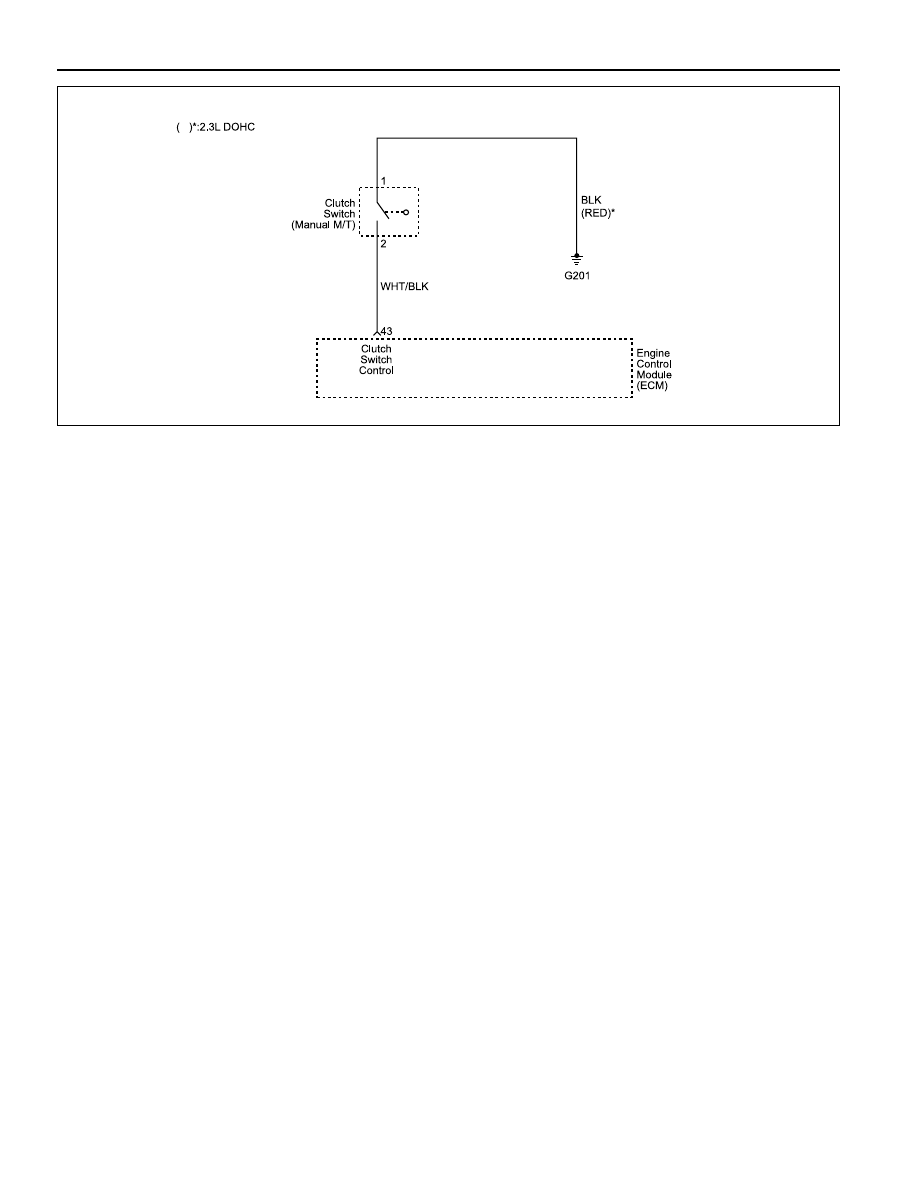

Circuit Description

Clutch switch plausibility diagnosis detects whether no

clutch switch signal detects in the corresponding range

(vehicle speed, engine speed) and engine load exceeds

upper load threshold for more than minimum time.

Conditions for Setting the DTC

•••••

DTCs P0101, P0102, P0103, P0335, P0336 and

P0501 are not set.

•••••

Vehicle speed is less than 2.4 km/h.

•••••

Ignition status is on.

•••••

Engine speed is less than 1800 rpm.

•••••

Engine load is greater than 0.6 for more than 5

seconds.

•••••

Start end is reached.

Action Taken When the DTC Sets

•••••

The Malfunction Indicator Lamp (MIL) will illuminate

after two consecutive driving cycles in which the diag-

nostic runs with the fault active.

•••••

The ECM will record operating conditions at the time

the diagnostic fails. This information will be stored in

the Freeze Frame and Failure Records buffers.

•••••

A history DTC is stored.

Conditions for Clearing the MIL/DTC

•••••

The MIL will turn off after three consecutive driving

cycles in which the diagnostic runs without a fault.

•••••

A history DTC will clear after 40 consecutive warm-

up cycles without a fault.

•••••

The DTC(s) can be cleared by using the scan tool.

Diagnostic Aids

An intermittent problem may be caused by a poor con-

nection, rubbed-through wire insulation, or a wire that is

broken inside the insulation.

Any circuitry, should be thoroughly checked for the fol-

lowing conditions:

•••••

Backed-out terminals

•••••

Improper mating

•••••

Broken locks

•••••

Improperly formed

•••••

Damaged terminals

•••••

Poor terminal-to-wire connection

•••••

Physical damage to the wiring harness

Test Description

Number(s) below refer to the step(s) number on the

Diagnostic Table.

1. Euro On-Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure

records data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

9. The replacement ECM must be reprogrammed. Re-

fer to the latest Techline procedure for ECM repro-

gramming.

YAB1F240