SsangYong Musso. Manual - part 121

1F-68 ENGINE CONTROLS

SSANGYONG Y158

29

Check for an open wire between the cooling fan relay

(LH high) connector terminal 30 and engine fuse block

fuse Ef5 and repair as necessary.

Is the repair complete?

1. Turn the ignition OFF.

2. Replace the cooling fan relay (LH high).

Is the action complete?

Replace the cooling fan motor (LH).

Is the action complete?

1. Turn the ignition OFF.

2. Disconnect the cooling fan relay (RH low) connector.

3. Start the engine.

4. Turn the A/C switch ON.

5. With a test light connected to battery, probe the

cooling fan relay (RH low) connector terminal 85.

Is the test light ON?

With a test light connected to battery, probe the cooling

fan relay (RH low) connector terminal 87.

Is the test light ON?

With a test light connected to ground, probe the cooling

fan relay (RH low) connector terminal 86.

Is the test light ON?

With a test light connected to ground, probe the cooling

fan relay (RH low) connector terminal 30.

Is the test light ON?

1. Turn the ignition OFF.

2. Replace the cooling fan relay (RH low)

Is the action complete?

Check for an open wire between the cooling fan relay

(RH low) connector terminal 85 and FATC controller

terminal A16 (or Manual A/C controller terminal 1) and

repair as necessary.

Is the repair complete?

Check for an open wire between the cooling fan relay

(RH low) connector terminal 87 and the cooling fan relay

(RH high) connector terminal 87 and repair as neces-

sary.

Is the repair complete?

Check for an open wire between the cooling fan relay

(RH low) connector terminal 86 and I/P fuse block fuse

F19 and repair as necessary.

Is the repair complete?

Check for an open wire between the cooling fan relay

(RH low) connector terminal 30 and engine fuse block

fuse Ef5 and repair as necessary.

Is the repair complete?

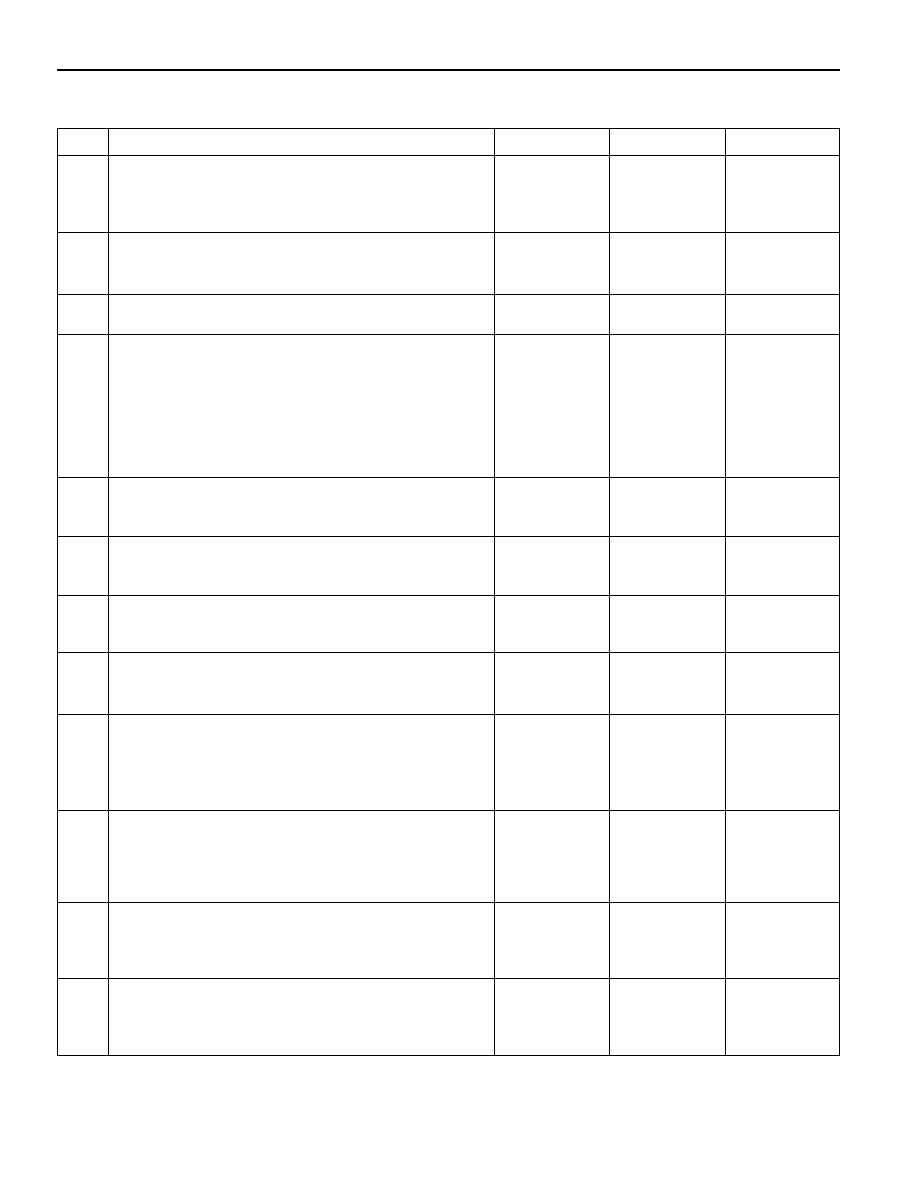

Step

Action

Value(s)

Yes

No

Engine Cooling Fan Circuit Check - with A/C (Cont’d)

-

System OK

-

30

31

34

-

Go to Step 33

Go to Step 38

32

-

Go to Step 35

Go to Step 39

35

-

Go to Step 36

Go to Step 40

36

-

Go to Step 37

Go to Step 41

38

-

System OK

Go to “7B or

7D section”

39

-

System OK

-

40

-

System OK

-

41

-

System OK

-

-

System OK

-

-

System OK

-

37

-

System OK

-