SCANIA MARINE ENGINES (specification) - part 4

Standard equipment

• Scania Engine Management System, EMS

• Unit injectors, PDE

• Turbocharger

• Fuel pre-filter with water separator

• Fuel filter

• Oil filter, full flow

• Centrifugal oil cleaner

• Oil cooler, integrated in block

• Oil filler, in engine block

• Oil dipstick, in block

• Starter, 2-pole 7.0 kW

• Alternator, 2-pole 100A

• Flywheel SAE 14

• Silumin flywheel housing, SAE 1 flange

• Front-mounted engine brackets

• Protection covers

• Closed crankcase ventilation

• Operator’s manual

Engines with heat exchanger:

• Sea water pump

• Heat exchanger with expansion tank

Optional equipment

• Hydraulic pump

• Side-mounted PTO

• Front-mounted PTO

• Exhaust connections

• Electrical base system

• Control and instrument panels

• Accelerator position sensor

• Engine heater

• Power pack engine bracket

• Stiff rubber suspension

• Air cleaner

• Studs in flywheel housing

• Reversible fuel filter

• Low coolant level reaction

• Variable idle speed setting

• Low and extra low oil sump

• Long oil dipstick

• Oil level sensor

• Bilge pump

SCANIA MARINE ENgINEs

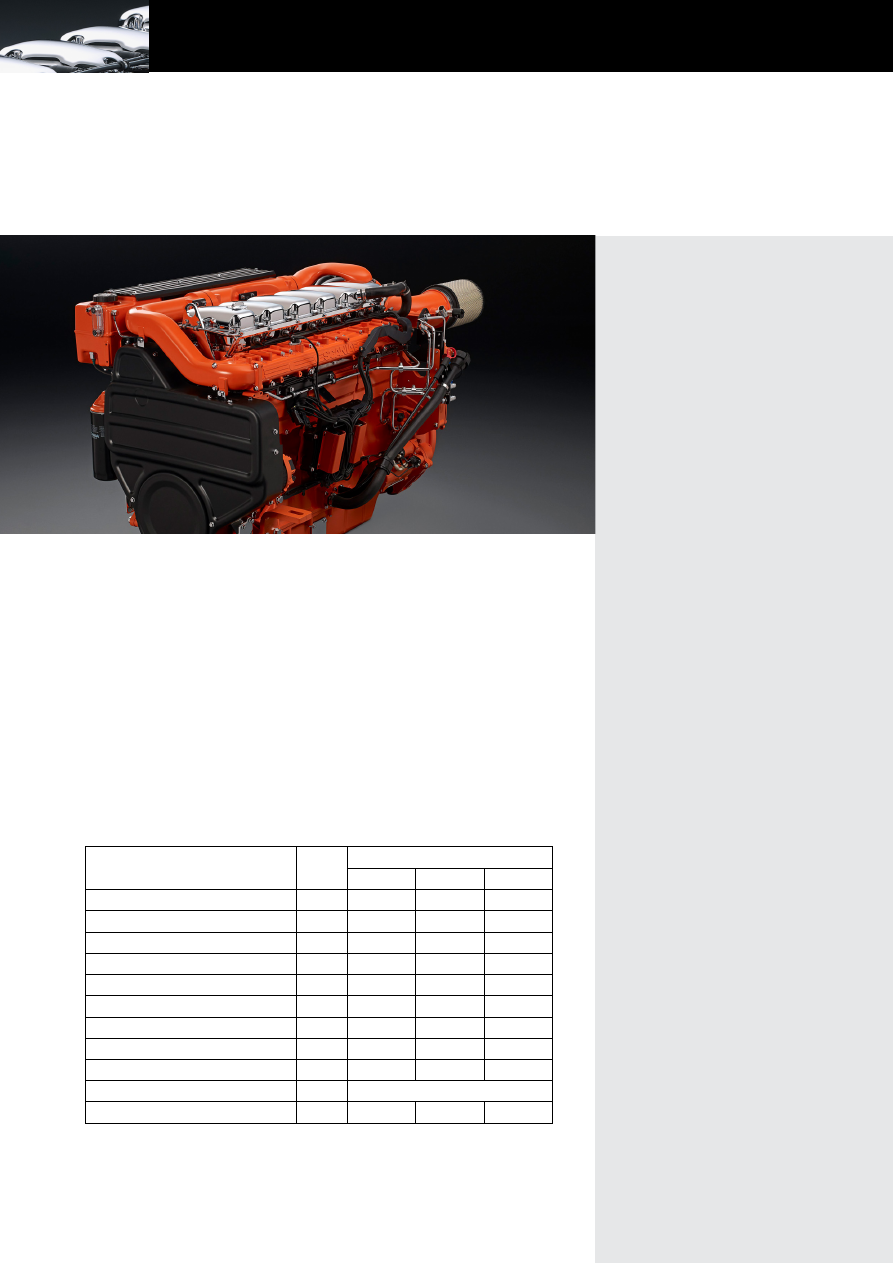

DI13 080M. 162 kW (220 hp)

IMO Tier II

The marine engines from Scania are based on a robust design with a strength

optimised cylinder block containing wet cylinder liners that can easily be exchanged.

Individual cylinder heads with 4 valves per cylinder promotes repairability and fuel

economy. The engines are type approved in all major classification societies.

The engine is equipped with a Scania developed Engine Management System,

EMS, in order to ensure the control of all aspects related to engine performance.

The injection system is based on electronically controlled unit injectors that gives low

exhaust emissions with good fuel economy and a high torque already at low revs.

The engine can be fitted with many accessories such as air cleaners, PTOs, transmis-

sions and type approved instrumentation in order to suit a variety of installations.

This specification may be revised without notice.

Engine speed (rpm)

Rating

1200

1500

1800

Gross power, full load (kW)

ICFN

126

152

162

Gross power, full load (hp, metric)

ICFN

171

207

220

Gross power, propeller curve (kW)

ICFN

59

103

162

Gross power, propeller curve (hp, metric)

ICFN

80

140

220

Gross torque (Nm)

ICFN

999

968

859

Spec fuel consumption. Full load (g/kWh)

202

208

227

Spec fuel consumption. 3/4 load (g/kWh)

208

216

239

Spec fuel consumption. 1/2 load (g/kWh)

219

232

255

Spec fuel consumption. Propeller curve (l/h)

16

27

44

Optimum fuel consumption (g/kWh)

197

Heat rejection to coolant (kW)

103

124

150

ICFN – Continuous service: Rated power available 1 h/1 h.

Unlimited h/year service time at a load factor of 100%