Scania 2.0 Instrumentation en-GB 2 495 120. Operator's manual - part 2

Main display

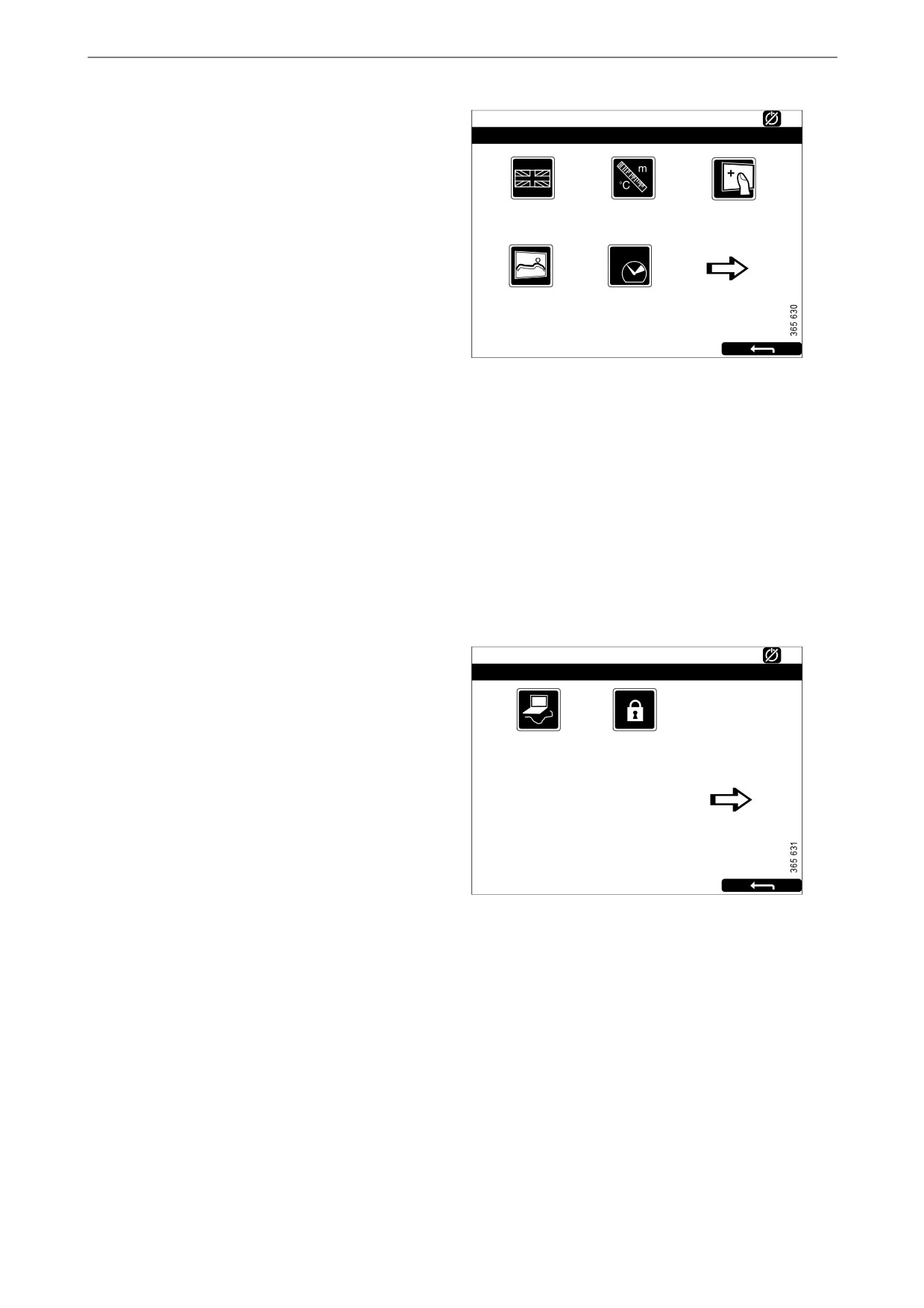

Language

Ready

Settings

123

Select language.

The languages which can be selected depend on

how the display is configured.

Language

Units

Calibrate Touch

[English]

[Metric]

Screen

Units

Select unit of measurement: Metric or U.S.

Wallpaper

Engine Overspeed

Calibrate Touch Screen

Test

[Inactive]

Calibrate the main display if necessary.

Wallpaper

Here you choose between different backgrounds

for instruments, menus and dialogue boxes.

Engine Overspeed Test

Select Active to activate the engine overspeed

test. When the overspeed test is activated, the

overspeed setting is temporarily reduced to a

nominal engine speed. Start the engine to carry

out the test.

The engine overspeed test is deactivated auto-

matically after a timeout or when actual engine

overspeed is detected in the test.

Connect a PC

Ready

Settings

123

This function is used when configuring the main

display and updating software. Contact an au-

thorised Scania workshop if any of this needs to

Connect a PC

Administration

be carried out.

[Locked]

Administration

In the administration section the main display is

configured, which can only be done by an au-

thorised Scania workshop. It is therefore pass-

word-protected.

16

Main display

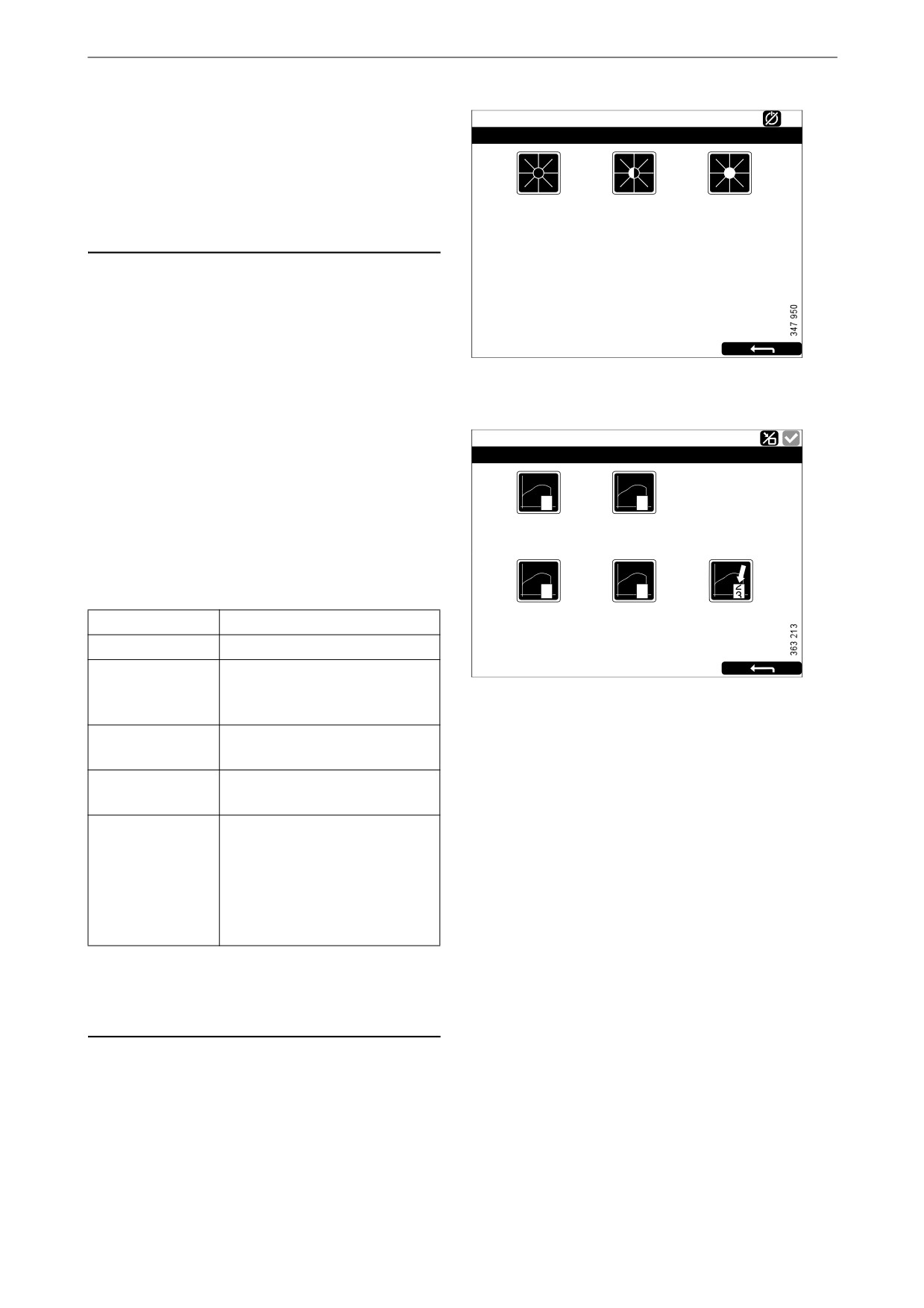

Screen Backlight

Ready

Backlight

The Screen Backlight button is in the Menu.

Note:

10 %

50 %

100 %

The button is only available if the display has

software version 2.11 or earlier.

When you press Screen Backlight, the Backlight

window opens. This increases and reduces the

brightness of the main display.

Torque Limit

Running

Torque Limit Selection

The Torque Limit button is in the Menu. When

you press it the Torque Limit Selection window

opens.

0

1

Cu r ve 0

Cu r ve 1

Torque limitation is different types of power

curves which the engine should follow. The

power curves are configured in SDP3.

2

3

Cu r ve 2

Cu r ve 3

Input Controlled

Adjustment

Description

[Cu r ve 0]

Curve 0

Maximum engine torque.

Curve 1

Maximum engine torque, an-

other lower engine torque re-

quested.

Curve 2

Customer defined engine

torque.

Curve 3

Customer defined engine

torque.

Input Controlled

Activation of curve 1-3 via in-

puts on the main display, if this

has been configured.

The button is only available if

the display has software ver-

sion 2.12.

Note:

Customer defined engine torques are always

lower than the maximum engine torque.

17

Main display

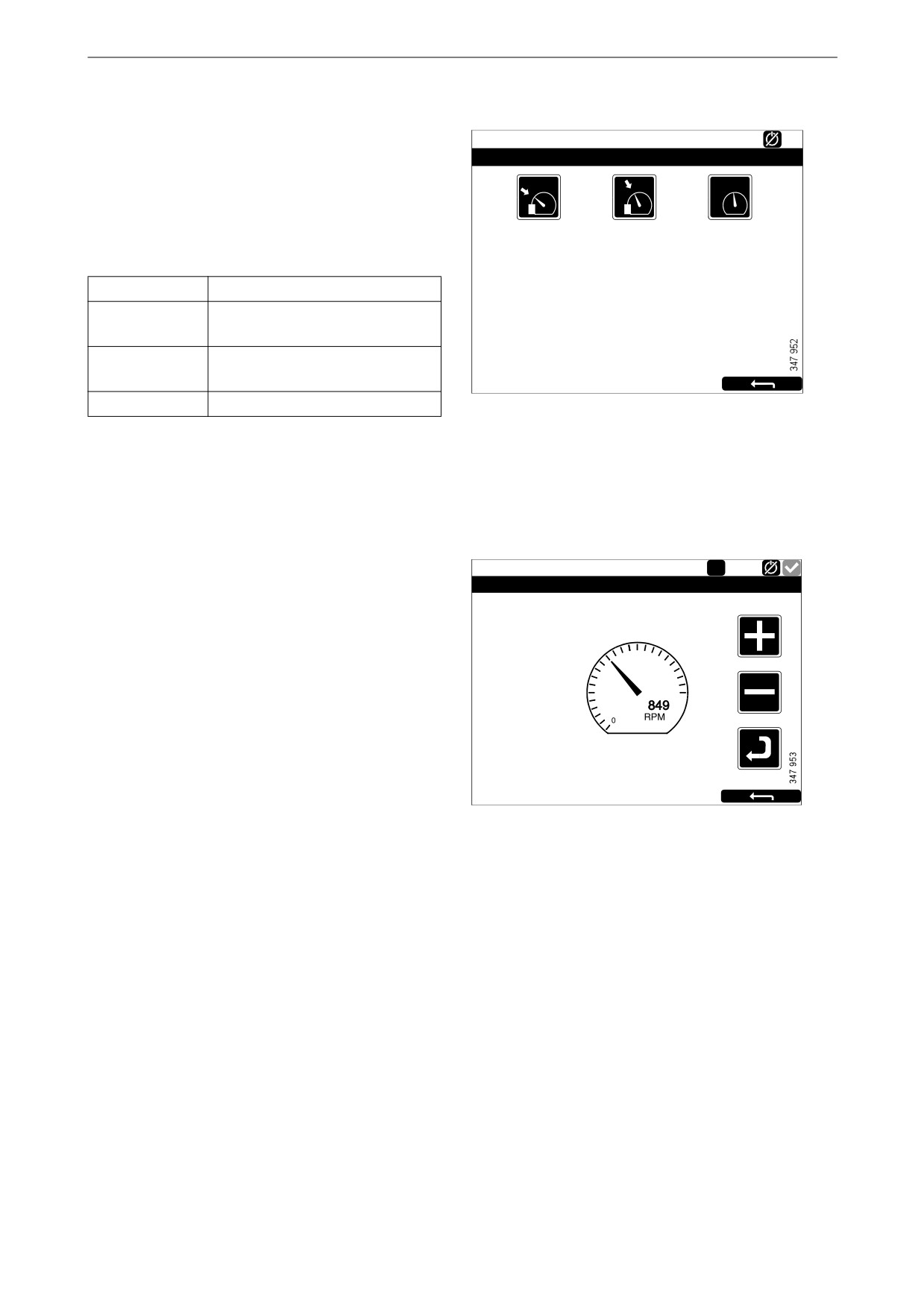

Fixed Speed

Running

The Fixed Speed button is in the Menu. When

Mode

you press it the Mode window opens.

Here you activate and deactivate the engine

1

2

speed setting. You can choose from the follow-

Fixed Speed Mode 1 Fixed Speed Mode 2 Fixed Speed Off

ing options:

Adjustment

Description

Fixed Speed

Activate engine speed setting 1.

Mode 1

Fixed Speed

Activate engine speed setting 2.

Mode 2

Fixed Speed Off

Deactivate engine speed setting.

In order to activate engine speed setting 1 or 2,

the engine must be running, the display must be

active and the throttle must be at 0%.

Adjust Fixed Speed

Running

1

The Adjust Fixed Speed button is in the Menu.

Fixed Speed Adjustment - Mode 1

When you press it the Fixed Speed Adjustment

window opens. Here you adjust engine speed

setting 1 and 2.

Engine Speed

1000

1500

You can only adjust an engine speed setting if

you have first activated it. This can be done in 2

500

2000

different ways:

• Via Menu > Fixed Speed in the main display,

see the previous section.

• Via the engine speed setting control in the

control panel, see the Control panelsection.

18

Main display

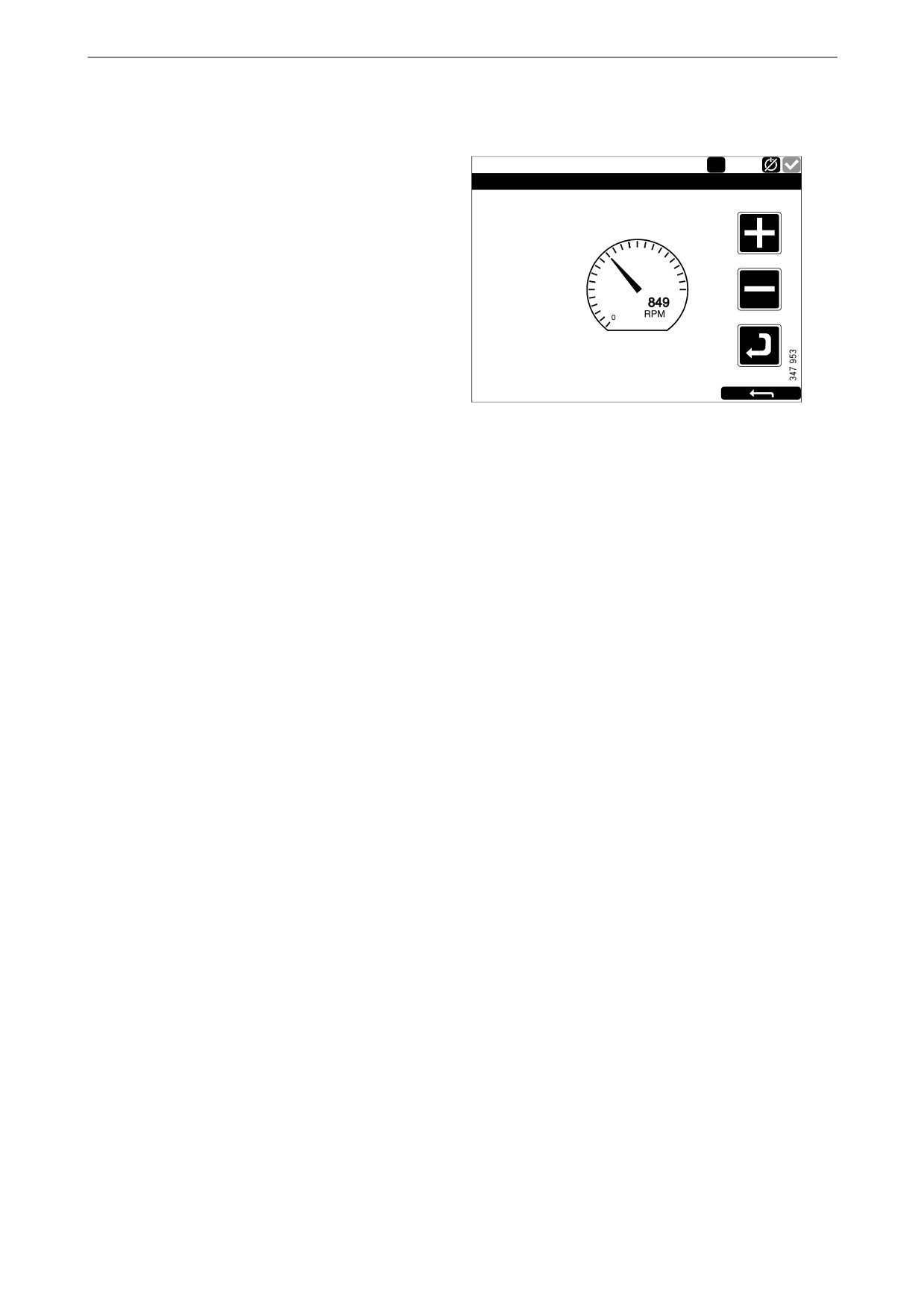

The following 2 engine speed settings are in Ad-

just Fixed Speed:

Running

1

• Fixed Speed Mode 1 is an engine speed which

Fixed Speed Adjustment - Mode 1

can be set between high and low idling. High

and low idling vary depending on the type of

engine.

Engine Speed

• Fixed Speed Mode 2 is an engine speed which

1000

1500

can be set between 450 and 2,000 rpm.

500

2000

Proceed as follows to adjust engine speed setting

1 or 2:

1. Select the engine speed setting to be adjust-

ed.

2. Press the activate button, i.e. the arrow but-

ton underneath the minus button for 3 to 6 s

to access the adjustment mode.

3. Step to the desired engine speed using the +

and - buttons.

4. Save the desired engine speed by keeping the

activate button pressed for 3 to 6 s. No con-

firmation is shown but the setting is saved.

5. Exit the menu by pressing the return arrow.

When either of the engine speed settings is acti-

vated, the engine speed goes up or down to the

last saved engine speed setting.

You can set torque limitation for both engine

speed settings via SDP3. The engine speed set-

tings are isochronous.

19

Main display

Log & Counters

The Log & Counters button is in the Menu.

Ready

Log & Counters

Here, a log of engine operating hours and all

warnings and alerts is shown. When you have

pressed Log & Counters, the following buttons

Counters

Event Log

Engine Se r vice

are shown:

Inte r val

Counters

This submenu contains counters for

Scania Fault

• the engine's total operating hours and fuel

Codes

consumption (Total).

• operating hours and fuel consumption since

start (Since Start).

• operating hours and fuel consumption since

reset (Since Reset).

The values for Since Start are reset automatically

each time the engine is started.

The values for Since Reset are reset by pressing

Reset at the bottom left of the Counters window.

Event Log

All events (warnings and alarms) are saved in the

main display and can be shown in this menu.

Select an event to see information on when it

first occurred, when it was acknowledged (if it is

possible to acknowledge the event) and when it

disappeared.

Engine Service Interval

Not used.

Scania Fault Codes

This shows Scania fault codes in DTC format.

These can make things easier when contacting a

Scania workshop.

Note:

The button is only available if the display has

software version 2.12.

20

Main display

Help

Ready

Help

The Help button is in the Menu. In Help there are

options for troubleshooting and for the main dis-

play software version and IP address.

Troubleshooting Version Information

Troubleshooting

Ready

Troubleshooting DCU

12

There are options here to troubleshoot the main

display.

Supply

Switch

4-20mA

First, press Troubleshooting DCU. Then select

using the buttons within the area in which the

troubleshooting should be carried out. Note that

there are 2 pages of options.

PT100

Communication

Version Information

Ready

Version Information - DCU 210

Information about the main display hardware

Engine #1

version, software version and operating system

Hardware Version:

4

Software Version:

2.12B10 - Build: 13107

is shown here. When connecting via CAN, the

Kernel Version:

120223

SDU Software Version:

1.43

software version of the engine control unit is

IP Address:

192.168.0.101

MAC Address:

00:14:2D:21:BC:8A

shown.

Cfg: DnVTypeApprovalConfig

The IP address of the display, which is needed if

the main display is to be connected to a PC, is

also shown here.

21

Auxiliary display

Auxiliary display

The auxiliary display largely works in the same

way as the main display. Therefore, only aspects

specific to the auxiliary display are described

here.

The auxiliary display reads the configuration

from the main display it is connected to. If the

configuration of the main display has been

changed, the auxiliary display adapts automati-

cally to the new configuration.

The auxiliary display can only monitor and con-

trol a main display.

Symbols in the status bar

In addition to the symbols shown in the main dis-

play (see the Main display layoutsection), the ac-

tive display symbol can also be shown in the

auxiliary display status bar. See illustration.

Active display symbol in the auxiliary display

22

Auxiliary display

Menu

Engine # 1 - Ready

Menu

12

You get to the auxiliary display main menu in the

same way as with the main display:

Settings

Backlight

Torque Limit

[100%]

[Curve 0]

• Press in the middle of the display for 1 s. on

one of the instrument pages, or

• press the Menu button in the Shortcut Menu

window.

Fixed Speed

Adjust Fixed Speed

[Off]

When the main menu is opened the most recently

used function is preselected.

In the following section only the Settings and Ac-

Menu, page 1

tive Station buttons are described, as all the other

buttons work in the same way as with the main

display.

Engine # 1 - Ready

Menu

12

Active Station

Log & Counters

Camera

[None]

Settings

Help

The Settings button is the first button on page 1

of the Menu. In this section only the Sound but-

ton is described, as all the other buttons in Set-

tings have the same function as in the main

display.

Menu, page 2

Sound

The auxiliary display has a 3.5 mm output for

Engine # 1 - Ready

connection of external loudspeakers. The sound

Sound

from external loudspeakers is different to the

sound from the buzzer, and different sounds are

connected to different events.

Button Beep

Sound

[Enabled]

Configuration

• With the Sound Configuration button, select

[Buzzer]

either external loudspeaker or the inbuilt

buzzer.

Settings > Sound

23

Auxiliary display

Active Station

Auxiliary # 8 - Running

Active Station

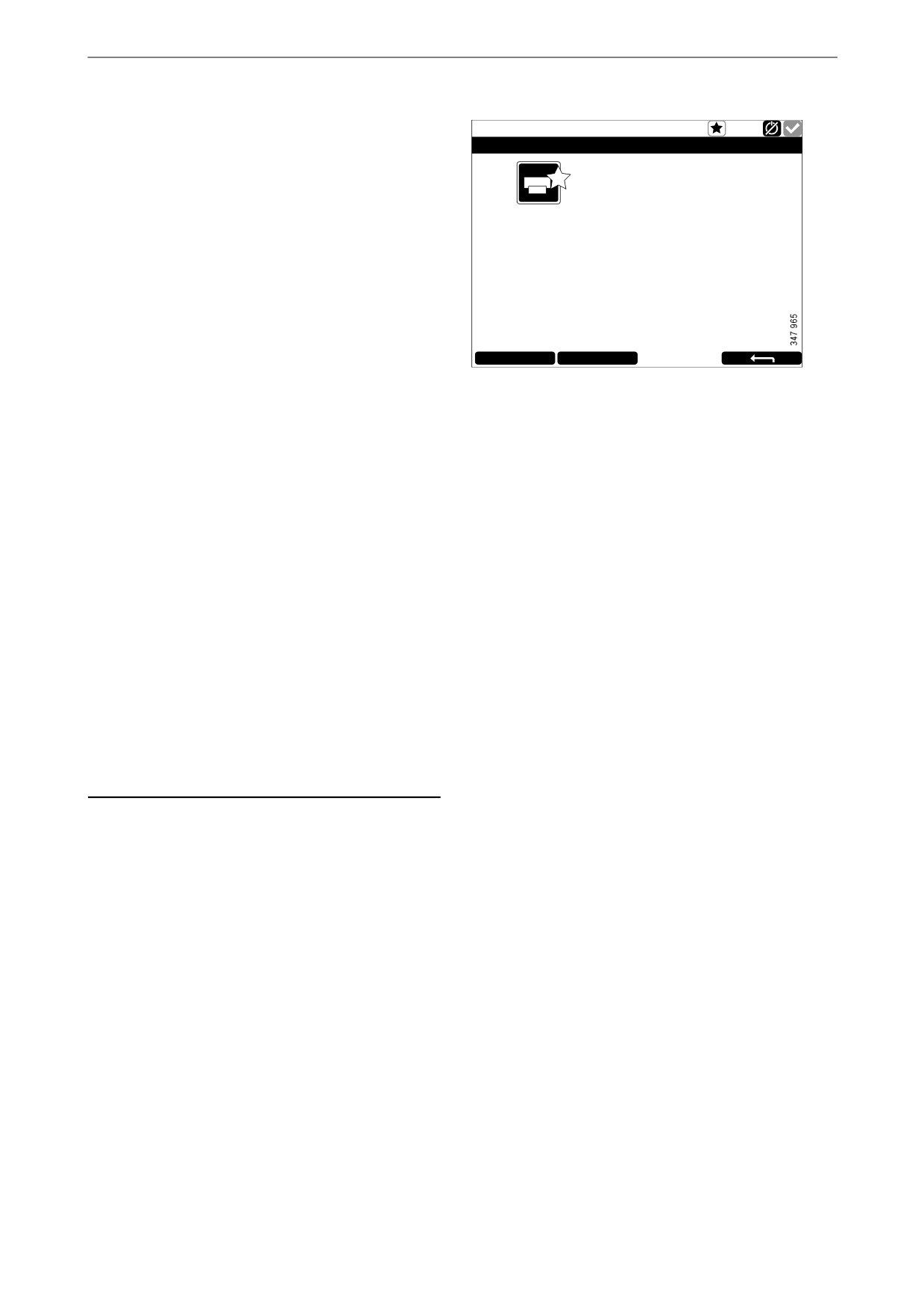

The Active Station button is the first button on

page 2 of the Menu.

Here, you activate and deactivate the option for

Running

the auxiliary display to have active display sta-

[This Station]

Auxiliary #8

tus, i.e. Active Station.

There may be several auxiliary displays in the

system controlling the same engine, but only one

auxiliary display can be active at any time.

Request

Release

Activating Active Station status

How to request that the auxiliary display become

an active display:

• Select an engine and press Request.

A request is sent to the auxiliary display which

currently has active display status.

If the engine icon has a yellow star in the status

bar at the top of the window, as in the illustration,

this means that the engine is currently being con-

trolled by this auxiliary display.

Note:

If there is only one auxiliary display in the sys-

tem, it still may not be the active display.

When you have activated Active Station once,

the setting is saved, even when the auxiliary dis-

play is restarted.

24

Alarm list

Deactivating Active Station status

Auxiliary # 8 - Running

Active Station

You can also deactivate the auxiliary display Ac-

tive Station status. Other auxiliary displays with

lower priority can then control the engine. Pro-

ceed as follows:

Running

[This Station]

Auxiliary #8

• Select an engine and press Release.

Request

Release

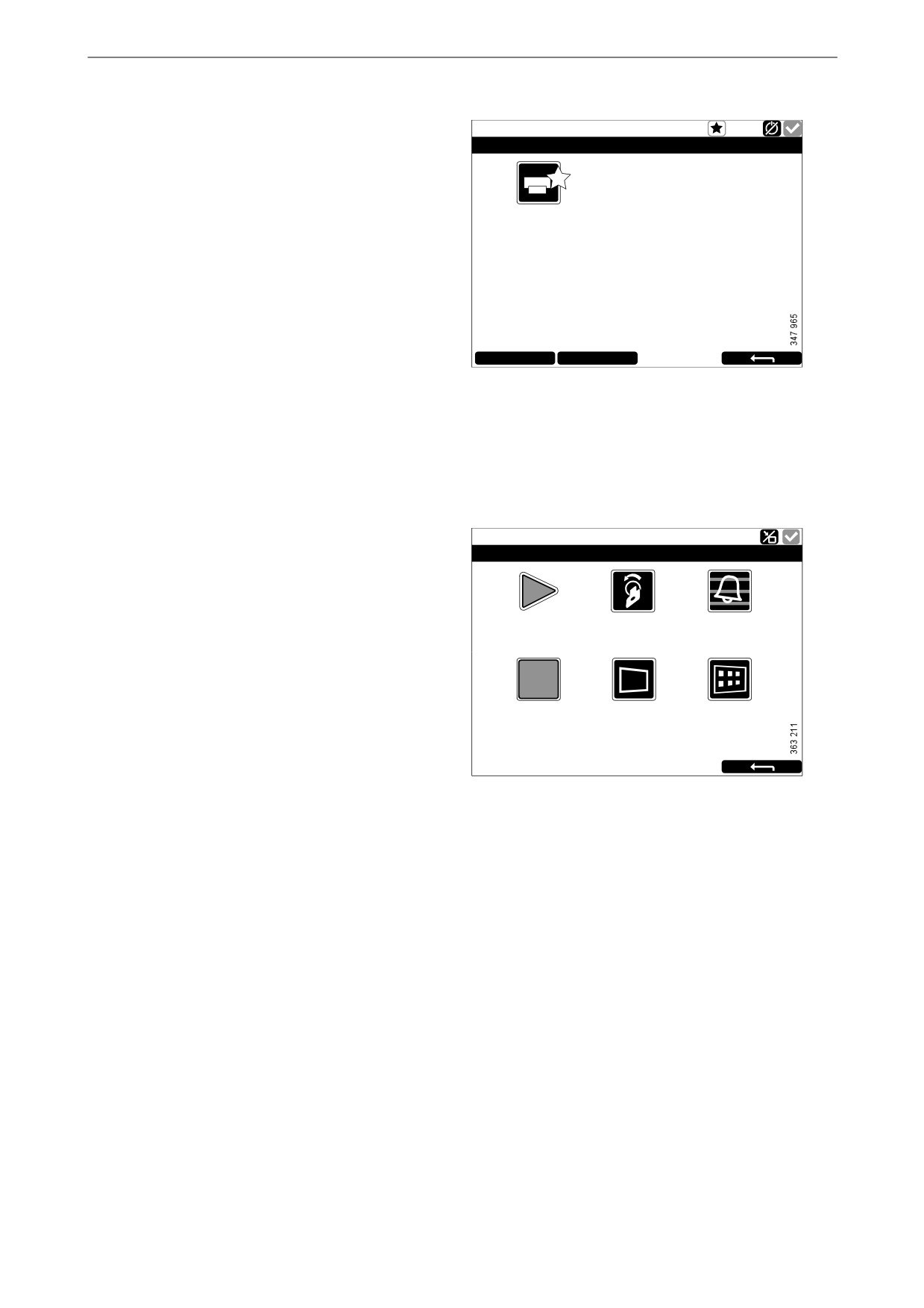

Alarm list

Ready

Sho r tcut Me nu

The alarm list is displayed and functions in the

0

1

same way on the main display and the auxiliary

display. In the alarm list warnings and diagnosis

Sta r t Engine

Ignition off

Ala r m List

messages are also shown.

There are 2 different ways to get to the alarm list

in the main display and auxiliary display:

Stop Engine

Bla ck Panel Mode

Me nu

• Press in the upper right-hand corner on one of

[Ena bled]

the instrument pages.

• Press the Alarm List button in the Shortcut

Menu window.

25

Alarm list

Typefaces and background

colours

Ready

Alarm list

All Alarms

The following principles apply to how warnings

2: Throttle Position

and alarms are shown in the alarm list:

• An event which is not acknowledged is dis-

played using bold.

• An acknowledged event is displayed using

normal text.

• An alarm and an engine shutdown are dis-

played using a red background. During en-

gine shutdown, a stop signal is also displayed.

Ack Alarms

Panel Alarms

Engine Diag.

• A warning is displayed using a yellow back-

ground.

• A diagnosis message is displayed using a

white background.

• An event which is not acknowledged and has

turned inactive is displayed using a grey

background.

Example: The coolant temperature has ex-

ceeded the limit value and then returned to a

normal level before the operator has had time

to acknowledge the event.

This table lists examples of how different

events are shown in the alarm list.

Alarm list

Type of alarm

Display

New active alarm or engine shutdown.

Bold with red background.

Acknowledged active alarm or engine shutdown.

Red background.

Not acknowledged inactive alarm.

Red text with grey background.

New active warning.

Bold with yellow background.

Acknowledged active warning.

Yellow background.

Not acknowledged inactive warning.

Yellow text with grey background.

New active diagnostic message.

Bold with white background.

Acknowledged diagnostic message.

White background.

Not acknowledged inactive diagnostic message.

Black text with grey background.

26

Alarm list

Filtering alarms

Ready

Alarm list

All Alarms

In the alarm list, the alarms can be filtered in 3

2: Throttle Position

different groups:

• All alarms

• Display alarms

• Diagnostics

You activate the different filters by pressing the

respective section at the bottom of the display.

On line 2 in the alarm list, the filter which is ac-

tive is displayed.

Ack Alarms

Panel Alarms

Engine Diag.

Turning off the buzzer during

an alarm

The buzzer is switched off when the alarm list is

opened. If the buzzer begins to sound when the

alarm list is open, you can switch it off by press-

ing Ack Alarms.

Acknowledging 1 alarm

In the alarm list:

• Select the alarm to be acknowledged. If there

is more information to display the row will be

extended.

• Press Ack Alarms.

Acknowledging all alarms

In the alarm list:

• Keep the Ack Alarms button depressed for 1

second.

Note:

Active alarms will remain in the alarm list.

Alarms from safety device unit

If the alarm is generated via the safety device

unit, it must be acknowledged in both the safety

device unit and on the main display.

27

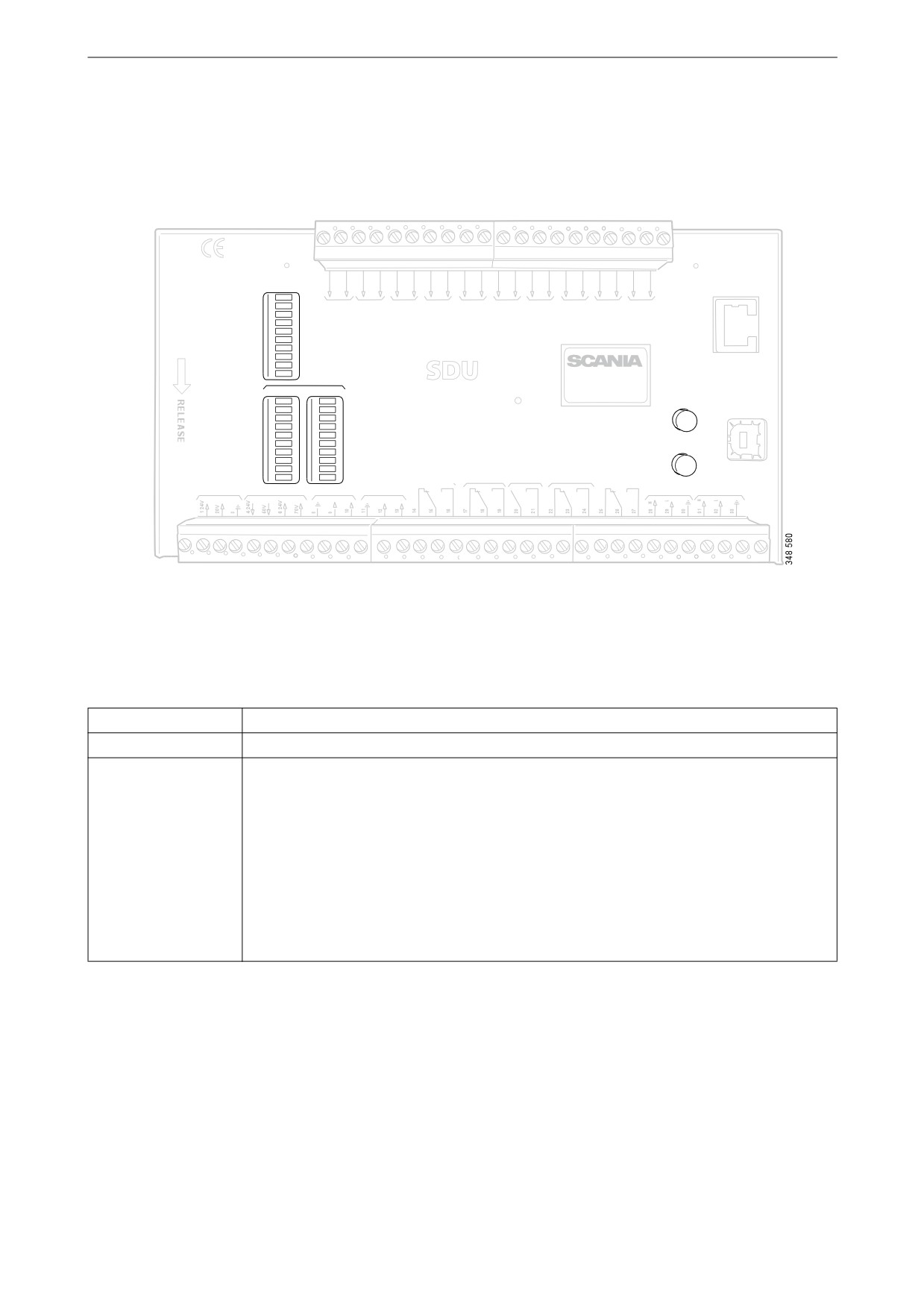

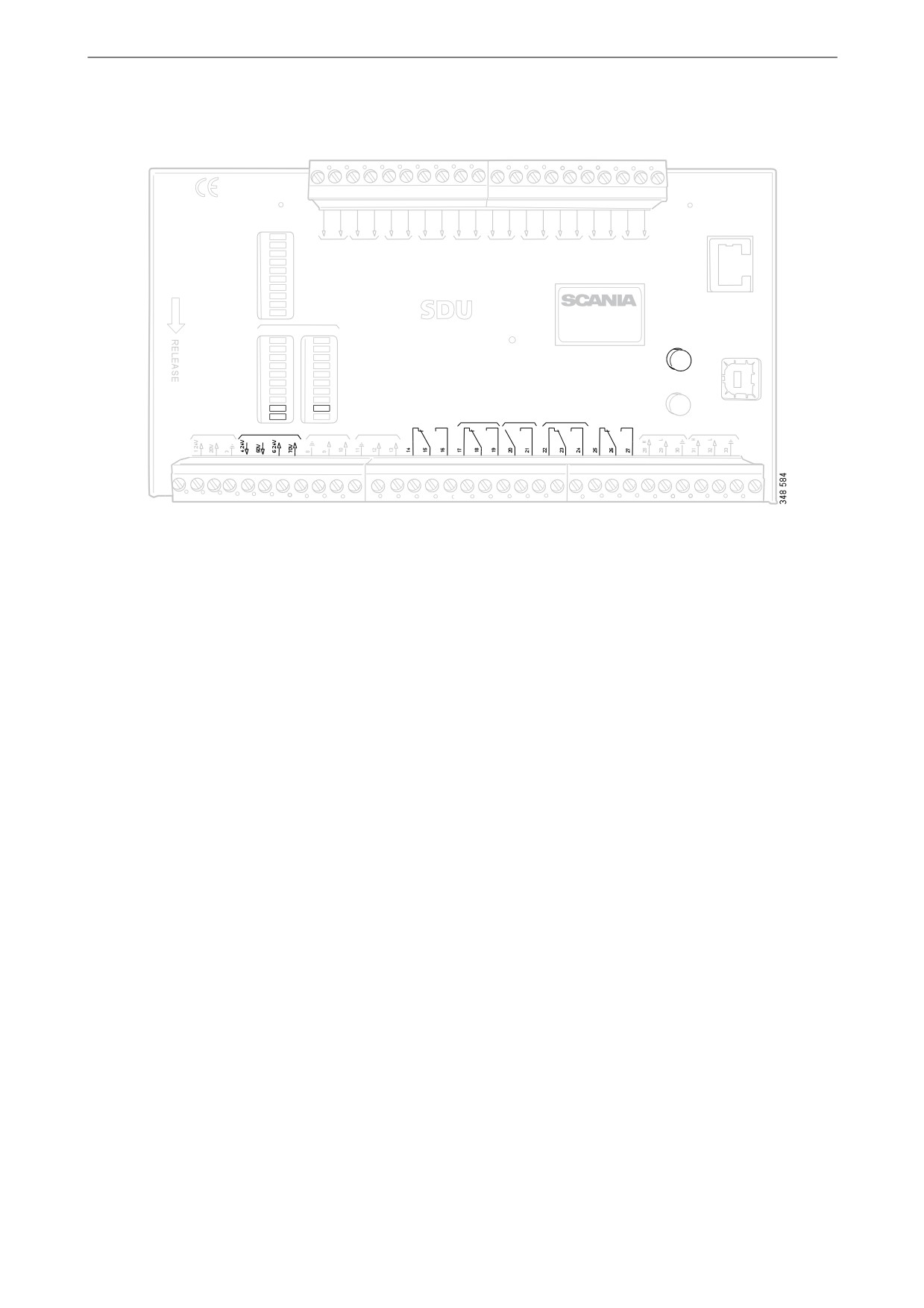

Safety device unit

Safety device unit

The safety device unit has its own monitors and sensors. An alarm which has been generated via the safety

device unit must also be acknowledged on the main display.

COM 3

STATUS

CONFIGURA TION

ETHERNET

PO WER

CRANK CUT OFF

SWITCH 1

SWITCH 2

SWITCH 3

SWITCH 4

SWITCH 5

SWITCH 6

SWITCH 7

SWITCH 8

SHUTDO WN

ACKNO WLEDGE

RUNNING

OVERRIDE

TACHO 1

TACHO 2

SHUTDO WN O VERRIDE

B UZZER

COM 1

COM 2

COM 3

shutdo wn unit

SHUTDO WN

FAULT

SWITCH 1

SWITCH 1

A CKNO WLEDGE

COM 4

SWITCH 2

SWITCH 2

USB

SWITCH 3

SWITCH 3

SWITCH 4

SWITCH 4

SWITCH 5

SWITCH 5

SWITCH 6

SWITCH 6

O VERSPEED

TEST

SWITCH 7

SWITCH 7

SWITCH 8

SWITCH 8

SHUTDO WN

SHUTDO WN COIL

CRANK

OVERSPEED

SHUTDO WN O VERIDE SHUTDO WN

CUT OFF

B UZZLER

FAULT

RUNNING

COM 2

COM 1

RS 485

SUPPL Y

SHUTDO WN COIL

TACHO 1

TACHO 2

DCU LINK

MODB US R TU

Safety device unit.

Buttons

Button

Description

Acknowledge

With the Acknowledge button all faults and engine shutdowns are acknowledged.

Overspeed Test

How to carry out an overspeed test: When the engine is switched off, keep the Over-

speed Test button depressed until the Overspeed LED starts flashing quickly. The safe-

ty device unit is now in test mode, and the limit value for engine overspeed is reduced

to 95% of the set overspeed limit value. Then start the engine.

The overspeed test can be deactivated in 3 different ways:

• The test is completed and is finished with an engine shutdown due to overspeed at

95% of the set overspeed limit value.

• Press the Overspeed Test button.

• Automatic deactivation after 5 minutes.

28

Safety device unit

LEDs

The LEDs indicate status, engine shutdown or faults. When an LED is flashing, there is a new event which

has not been acknowledged. When an LED is constantly on, there is an event which has been acknowledged

but which is still active.

Status LEDs

LED

Description

Power

Lights when the safety device unit is supplied with a voltage above 21 V. Flashes if

voltage is below 21 V. Alarm if voltage is below 21 V for more than 30 s. If voltage

drops to below 18 V the safety device unit switches off all channels.

Crank Cutoff

Lights when the engine speed is above the set limit value.

Running

Lights when the safety device unit gets a signal that the engine speed is above the set

limit value, which is normally 400 rpm.

Tacho 1/Tacho 2

Lights when the engine speed is above 5 rpm.

Shutdown Override

Lights when engine shutdown override control is activated.

Buzzer

Lights when the buzzer is activated.

COM 1

Flashes when the safety module communicates with the main display.

COM 2

Flashes when the safety module communicates via Modbus RTU interface.

COM 3

Flashes when the safety module communicates with the Ethernet interface.

LEDs for engine shutdown and faults

Shutdown

LED

Description

Switch 1

Lights at engine shutdown due to impermissible engine oil pressure.

Switch 2

Lights at engine shutdown due to high coolant temperature.

Switch 3

Lights at engine shutdown due to remote controlled emergency stop.

Switch 4

Lights at engine shutdown due to too high coolant pressure.

Switch 5-8

Lights at engine shutdown due to customer configured settings.

Shutdown

Lights at all engine shutdowns.

Overspeed

Lights at engine overspeed. Flashes rapidly at engine overspeed test.

Fault

LED

Description

Switch 1-8

Lights at open circuit for the respective sensor.

Shutdown Coil

Lights at open circuit for the Shutdown Coil output.

Shutdown Override

Lights at open circuit for the Shutdown Override input.

29

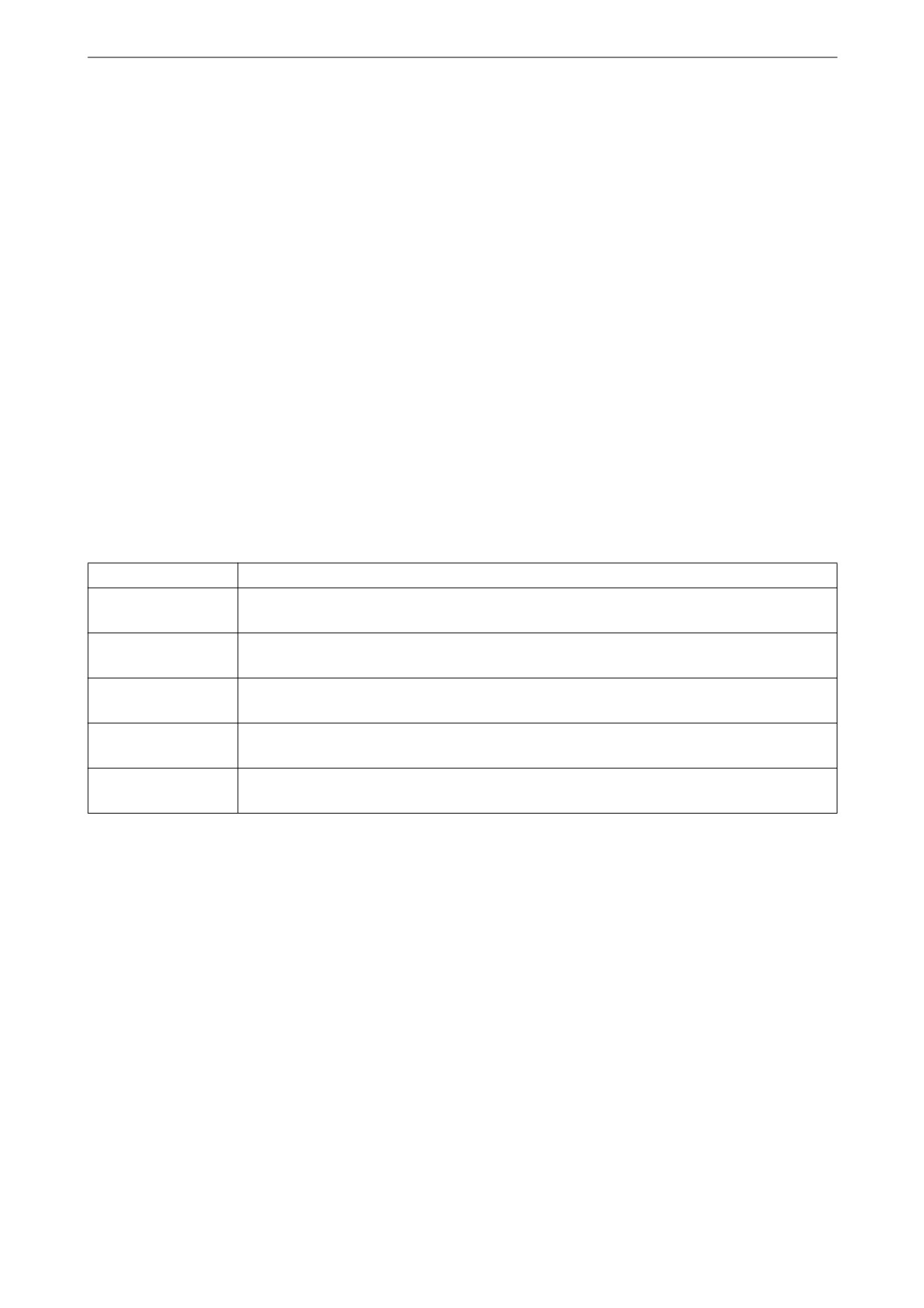

Safety device unit

Engine shutdown at engine overspeed

COM 3

STATUS

CONFIGUR ATION

ETHERNET

POWER

CRANK CU TOFF

SWITCH 1

SWITCH 2

SWITCH 3

SWITCH 4

SWITCH 5

SWITCH 6

SWITCH 7

SWITCH 8

SHUTD OWN

A CKN OWLEDGE

R UNNING

OVERRIDE

TACHO 1

TACHO 2

SHUTD OWN OVERRIDE

B UZZER

COM 1

COM 2

COM 3

shutd o wn unit

SHUTD OWN

FAULT

SWITCH 1

SWITCH 1

A CKN OWLEDGE

COM 4

SWITCH 2

SWITCH 2

USB

SWITCH 3

SWITCH 3

SWITCH 4

SWITCH 4

SWITCH 5

SWITCH 5

SWITCH 6

SWITCH 6

OVERSPEED

TEST

SWITCH 7

SWITCH 7

SWITCH 8

SWITCH 8

SHUTD OWN

SHUTD OWN COIL

CRANK

OVERSPEED

SHUTD OWN OVERIDE SHUTD OWN

CU TOFF

B UZZLER

FAULT

R UNNING

COM 2

COM 1

RS 485

SUPP LY

SHUTD OWN COIL

TACHO 1

TACHO 2

DCU LINK

MOD B US R TU

Safety device unit.

If a signal is sent to one of the 2 engine speed inputs that the engine speed exceeds the limit value, the safety

device unit shuts off the engine.

Override of engine shutdown

It is not possible to override engine shutdown at engine overspeed. The engine is always shut off in case of

engine overspeed.

Indication

The red Overspeed LED lights. The red Shutdown LED lights.

Acknowledgement

When engine shutdown has occurred: Acknowledge the engine shutdown with the Acknowledge button on

the safety device unit.

30

Safety device unit

Engine shutdown due to sig-

Shutdown Coil

nal from sensor

The Shutdown Coil output is activated at all en-

gine shutdowns. The output is deactivated

If any of the sensors indicates engine shutdown

8 seconds after the engine has stopped.

the safety device unit activates engine shutdown.

Detecting an open circuit

Override of engine shutdown

If there is an open circuit in the electrical cables

All sensor channels can be configured to disre-

connected to junction block 4 and 5, the red

gard the engine shutdown override signal.

Shutdown Coil LED lights. The impedance

should be in the region of 300-700 ohms.

Indication

The red Switch LED for the corresponding sen-

Power supply

sor lights. The red Shutdown LED lights.

Shutdown Coil is supplied with power separately

via junction block 6 and 7.

Acknowledgement

When engine shutdown has occurred: Acknowl-

edge the engine shutdown with the Acknowledge

button on the safety device unit.

Relays

Relay

Description

Shutdown

Is activated at all engine shutdowns. Active until the engine has been stopped and the

operator has acknowledged the event.

Crank Cutoff

Is activated at a set engine speed, which is normally 400 rpm. Is deactivated when the

safety device unit has obtained a signal that the engine has stopped.

Buzzer

Is activated for all new engine shutdowns and faults. Is deactivated when the operator

has acknowledged the event.

Fault

Fault indicator, i.e. is activated for all new faults. Is deactivated when the fault has been

acknowledged and has disappeared.

Running

Is activated at a set engine speed, which is normally 400 rpm. Is deactivated when the

safety device unit has obtained a signal that the engine has stopped.

31