Scania EMS Instrumentation 1 588 955 - part 1

Scania EMS

Instrumentation

1 588 955

1588955

1

Contents

Scania EMS Instrumentation

4

General

4

Instrument Panel (analogue)

6

General

6

Troubleshooting using flash codes for the EMS control unit

8

Overview of flashing codes for EMS control unit

9

Troubleshooting using flash codes for the EMS coordinator

10

Overview of flash codes for EMS coordinator

11

Scania Control Panel (SCP)

12

Remote Control Box (RCB)

17

Scania EMS Display (SED)

19

General

19

Function

19

Favourite screen

19

Information (4)

22

Fault codes (5)

24

Settings (6)

26

Alarm and fault code generation

34

1588955

3

Scania EMS Instrumentation

General

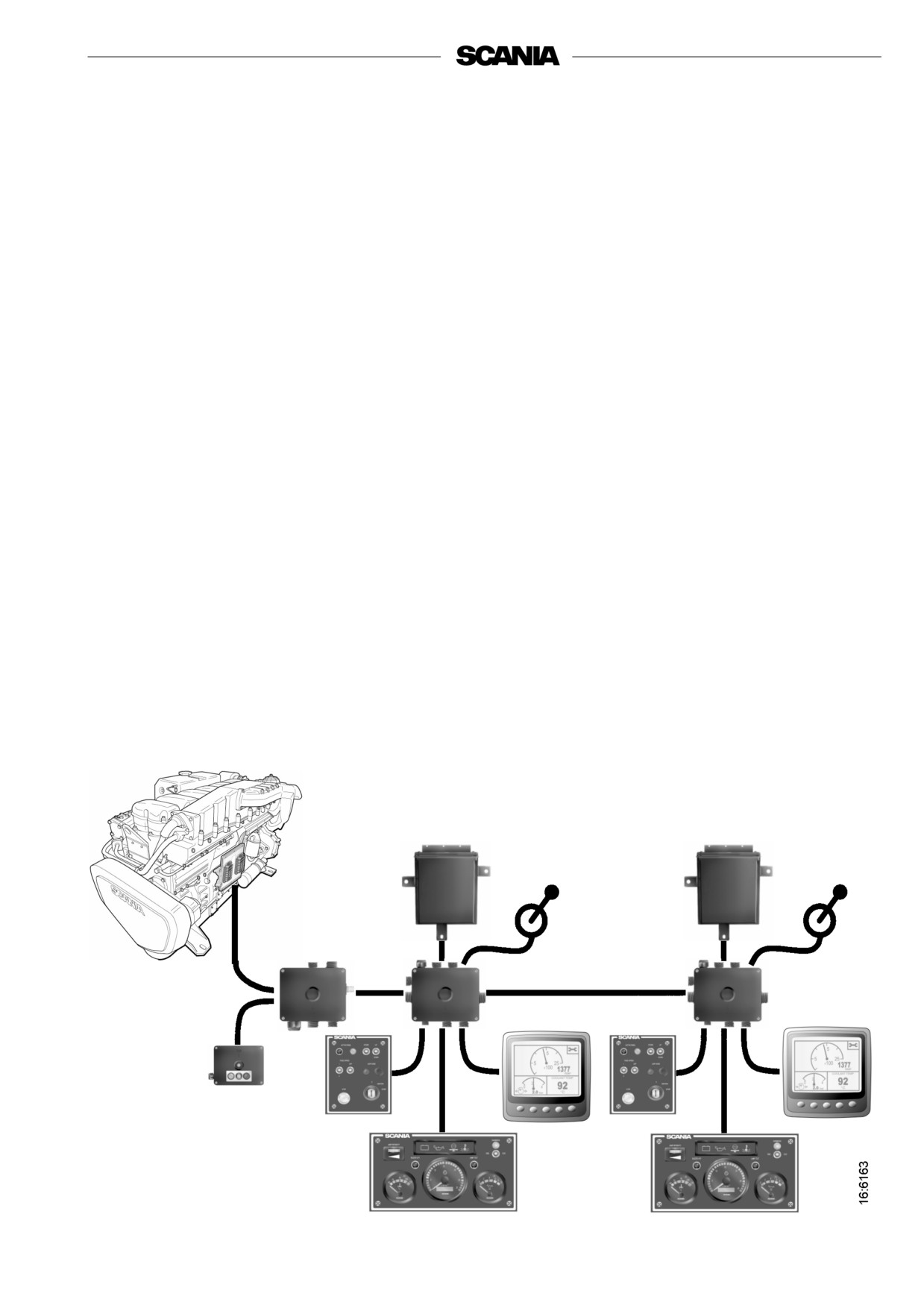

The base system comprises of the main supply box (MSB), the

junction box for the coordinator (CBC) and the coordinator (COO).

The main supply box is connected directly to the S6 control unit.

For this base system there are several different options for connection

to the system:

- Scania EMS digital display together with a control panel with

ignition key.

- A remote control box which enables controlling the engine from the

engine room.

- An analogue instrument panel instead of the digital display or

together with it.

- A Scania APS sensor (accelerator pedal sensor).

- In addition, the system can be doubled if there are two control

pulpits.

The whole system for instrumentation is Plug and Play which makes it

very simple to install.

See illustration of dual system on the next page.

In this Operator's manual, only the analogue instrument panel 9,

Scania EMS display 10 and Control Panel, 8 and 9, are described.

4

1588955

1

3

4

7

8

12

9

9

2

10

10

10

5

6

11

11

1. Control Unit S6

2. Main Supply Box

3. Coordinator

4. Coordinator

5. Connection Box Coordinator (master)

6. Connection Box Coordinator (slave)

7. Control Panel (master)

8. Control Panel (slave)

9. Instrument Panel

10. Scania EMS Display

11. Accelerator Position Sensor

12. Remote Control Box

Scania instrumentation, dual system

1588955

5

Instrument Panel (analogue)

General

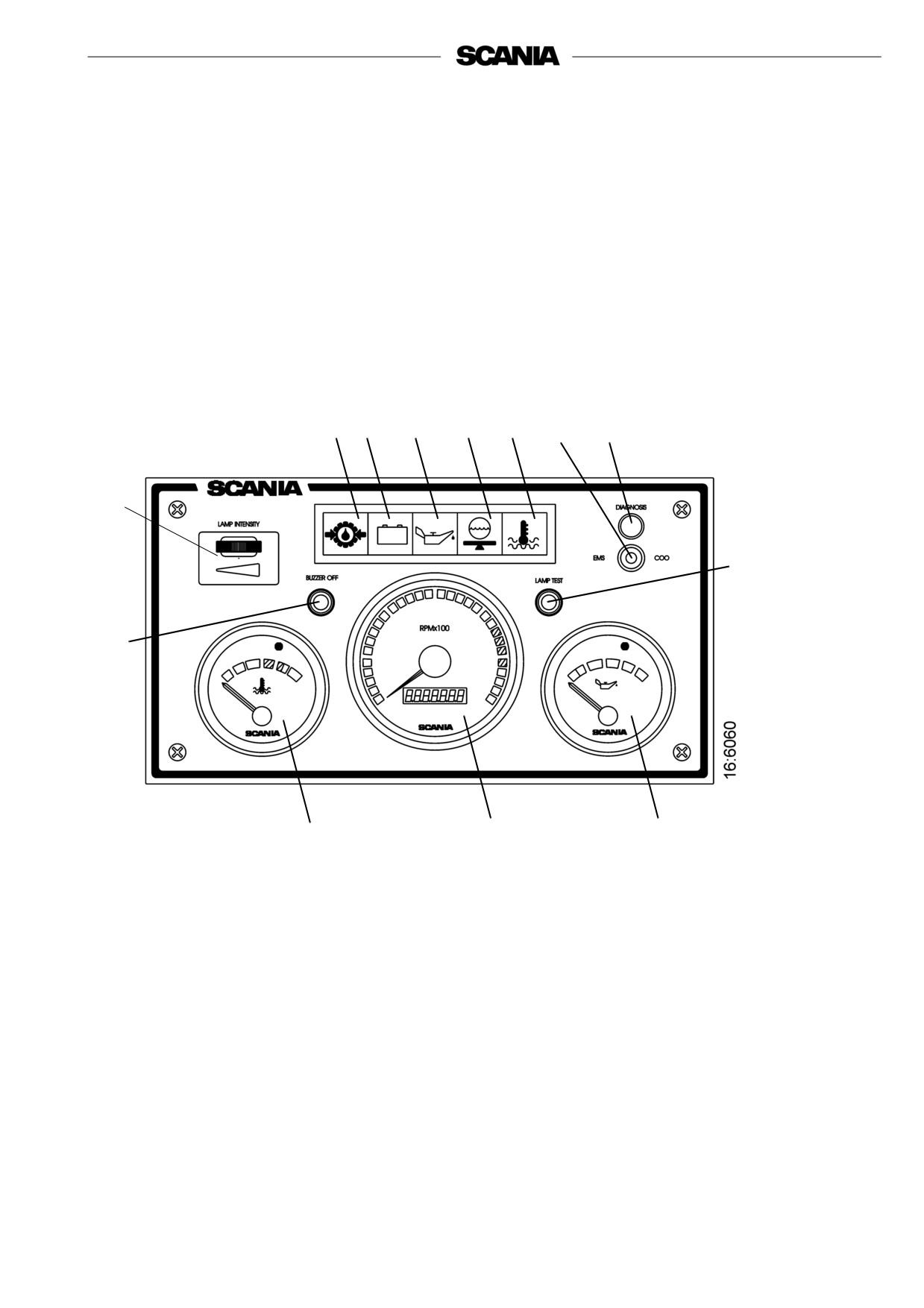

The analogue instrument panel has instruments for reading rotation

speed with hour counter, coolant temperature and oil pressure as well

as switches and lamps for diagnosis and alarm.

The analogue instrument panel has the following functions:

Also see illustration on next page.

Lamp intensity (S54)

The intensity of the gauges can be regulated with this roller control.

Buzzer off (S51)

This button deactivates the buzzer sound on any existing alarm. The

warning lamp for the current alarm trigger will continue to illuminate

until the fault is rectified.

Lamp test (S52)

With this button it is possible to check that the system lamps are intact

and functioning. When the button is activated the coordinator will

activate all lamps on the panel and the buzzer will sound. The lamps

illuminate and the buzzer sounds as long as the button is depressed.

When the key in the control panel is turned to the Ignition position an

automatic lamp test takes place for 2 seconds and the buzzer sounds for

1 second.

Diagnosis EMS/COO (W21 and S53)

This is a 3-position switch which belongs to diagnostic lamp W21. The

diagnostic lamp remains lit for as long as the system has an active fault

code.

When the switch is activated in the direction of the COO for at least 1

second, the coordinator will send out any fault codes as flash codes on

the diagnostic lamp (W21).

When the switch is activated in the direction of the EMS for at least 1

second, the coordinator will send out any fault codes for the EMS the

control unit as flash codes on the diagnostic lamp (W21).

6

1588955

In order to read flash codes with dual instrumentation it is necessary to

demand diagnosis from the instrument panel where the coordinator in

question is connected.

For further information on reading and deleting flash codes, see

Troubleshooting using flash codes.

Warning lamps (W1, W4, W5, W6, W7)

On the warning lamp panel there are warning lamps for alternator

charging, oil pressure, coolant temperature and coolant level. Warning

lamp for hydraulic pressure is not used.

W6 W1 W5 W7 W4 S53 W21

S54

S52

S51

O1

O3

O2

O1

Tachometer with hour counter

O2

Coolant temperature gauge

O3

Oil pressure gauge

S51

Deactivation of buzzer

S52

Lamp test switch

S53

Diagnostic switch

S54

Rheostat for instrument lighting

W1

Charge warning lamp

W4

Warning lamp, coolant temperature

W5

Warning lamp, oil pressure

W6

Warning lamp, hydraulic pressure

W7

Warning lamp, coolant level

W21

Diagnostic lamp

Scania analogue instrument panel

1588955

7

Troubleshooting using flash codes for the EMS

control unit

1.

Switch on the ignition. If the diagnostic lamp is on after 2 seconds

there is an active fault.

2.

Activate the diagnostic switch (S53) to the left to see the flash

codes for the control unit (EMS).

3.

A fault code will then flash on the diagnostic lamp (W21). This

flash code consists of long flashes (approximately 1 second long)

and short flashes (0.3 seconds long). Long flashes are equivalent

to tens and short flashes to units.

Example: long - short - short = fault code 12.

4.

Repeat this procedure until the first flash code is repeated. This

means that the entire fault code memory has been flashed out. If

the fault code memory is empty, only one long flash

approximately 4 seconds long will be given.

5.

See the flash code table on the next page for a description and

localisation of the fault.

6.

In order to obtain further information on the fault code, the

PC-based diagnostics tool or Scania EMS Display must be used.

Contact an authorised Scania workshop.

7.

The diagnostic lamp will stay on for as long as a fault is active.

Even if the lamp has gone off and the fault is no longer active, the

code can generally be read off in accordance with the instruction

above.

8.

When a fault has been rectified the fault code can be erased as

described below.

Erasing fault codes (flash codes)

1. Turn the ignition off. If there is dual instrumentation the ignition

must be switched off on both panels.

2. Activate the diagnostic switch in the direction of the flash codes,

i.e. to the left for EMS.

3. Turn the ignition on at the same time as holding the diagnostic

switch activated to the left (EMS) for 3 seconds.

4. This will erase passive fault codes which can be read off via flash

code for the relevant system. The rest of the fault code will remain

in the EEPROM and can only be deleted using the PC tool.

8

1588955

Overview of flashing codes for EMS control unit

Code

Description

Code

Description

PDE in cylinder 3: The solenoid valve does not

0

No fault detected.

53

work correctly.

Overspeed. One or both rotation speed

PDE in cylinder 4: The solenoid valve does not

11

54

sensors are indicating values above 3000 rpm.

work correctly.

Rotation speed sensor 1 faulty, or incorrect

PDE in cylinder 5: The solenoid valve does not

12

55

signal.

work correctly.

Rotation speed sensor 2 faulty, or incorrect

PDE in cylinder 6: The solenoid valve does not

13

56

signal.

work correctly.

Coolant temperature sensor faulty, or incorrect

PDE in cylinder 7: The solenoid valve does not

14

57

signal.

work correctly.

Charge air temperature sensor faulty, or

PDE in cylinder 8: The solenoid valve does not

15

58

incorrect signal.

work correctly.

Charge air pressure sensor faulty, or incorrect

16

59

Incorrect signal in extra analogue input.

signal.

Oil temperature sensor faulty, or incorrect

17

61

Incorrect control unit shutdown.

signal.

18

Oil pressure sensor faulty, or incorrect signal.

66

Shutdown due to coolant level

Starter motor function interrupted or not

20

Coolant level sensor faulty.

69

activated.

23

Fault code internally in the coordinator.

82

Rotation speed above ref.speed at start

Accelerator pedal / brake. If the accelerator

Fault in memory circuit (EEPROM) in control

24

and brake pedals have been operated

83

unit.

simultaneously.

Accelerator pedal sensor / idling switch

Data transfer to the control unit memory

25

84

Accelerator pedal sensor / kick-down switch

(EEPROM) has been interrupted.

Incorrect temperature internally in the control

27

Engine shutdown bypassed.

85

unit.

Internal fault in the control unit: Fault in

28

Shutdown due to oil pressure

86

hardware control.

31

Torque limitation due to oil pressure

87

Fault in control unit RAM.

32

Incorrect parameters for limp home function.

88

Internal control unit fault: Memory fault

33

Battery voltage incorrect or no signal.

89

Incorrect seal: Prohibited changes in software.

Emergency shutdown switch activated in

Rotation speed sensors faulty or not

37

accordance with CAN message from

93

connected.

coordinator.

43

CAN circuit faulty in the control unit.

94

Shutdown due to high coolant temperature.

Immobiliser function. Ignition key code

Torque limitation due to high coolant

47

96

incorrect.

temperature.

CAN message from the coordinator incorrect

48

98

Incorrect voltage supply to one of the sensors.

or missing.

Incorrect CAN version in control unit or

49

99

Internal hardware fault in the processor (TPU).

coordinator.

PDE in cylinder 1: The solenoid valve does not

51

work correctly.

PDE in cylinder 2: The solenoid valve does not

52

work correctly.

1588955

9

Troubleshooting using flash codes for the EMS

coordinator

1. Switch on the ignition. If the diagnostic lamp is on after 2 seconds

there is an active fault.

Important! The diagnostic lamp only indicates faults for the

coordinator connected to the instrument panel from which the

flash codes are read.

2.

Activate the diagnostic switch (S53) to the right to see the flash

codes for the coordinator (COO).

3.

A fault code will then flash on the diagnostic lamp (W21). This

flash code consists of long flashes (approximately 1 second long)

and short flashes (0.3 seconds long). Long flashes are equivalent

to tens and short flashes to units.

Example: long - short - short = fault code 12.

4.

Repeat this procedure until the first flash code is repeated. This

means that the entire fault code memory has been flashed out. If

the fault code memory is empty, only one long flash

approximately 4 seconds long will be given.

5.

See the flash code table on the next page for a description and

localisation of the fault.

6.

In order to obtain further information on the fault code, the

PC-based diagnostics tool or Scania EMS Display must be used.

Contact an authorised Scania workshop.

7.

The diagnostic lamp will stay on for as long as a fault is active.

Even if the lamp has gone off and the fault is no longer active, the

code can generally be read off in accordance with the instruction

above.

Erasing fault codes (flash codes)

1. Turn the ignition off. If there is dual instrumentation the ignition

must be switched off on both panels.

2. Activate the diagnostic switch in the direction of the flash codes,

i.e. to the right for the coordinator COO.

3. Turn the ignition on at the same time as holding the diagnostic

switch activated to the right (COO), for 3 seconds.

4. Any fault code that can be read by a flash code for the system in

question will be deleted. The rest of the fault code will remain in

the EEPROM and can only be deleted using the PC tool.

Important! It is only possible to delete fault codes for the

coordinator that is connected to the instrument panel from

which deletion is carried out.

10

1588955

Overview of flash codes for EMS coordinator

Flashing

Fault description

code

111)

Incorrect signal from the nominal rotation speed signal fine adjustment.

112)

Incorrect analogue signals from the accelerator pedal sensor.

121)

Incorrect analogue signal from the resistor module for governor setting.

Incorrect analogue signal from the resistor module for idling and fixed speed

122)

setting.

13

No communication (EMS) with the engine.

14

Short-circuit in the tachometer signal cable.

15

Faulty atmospheric pressure sensor.

17

Short-circuit in the coolant temperature gauge signal cable.

18

Short-circuit in the oil pressure gauge signal cable.

19

Short-circuit in the oil pressure lamp signal cable.

Different versions of the communications protocol between the coordinator and

21

EMS.

22

Faulty start switch or short circuit.

23

The supply voltage is too high.

24

The supply voltage is too low.

25

Check value from end of line (EOL) is incorrect.

26

Road speed sensor signal missing or incorrect.

27

The signals from the RCB (Remote Control Box) switches are implausible.

28

Incorrect signals from the droop-setting switches.

29

Faulty remote start switch or short circuit.

31

No communication from the slave coordinator or the master coordinator.

32

Short circuit in the signal cable to the coolant temperature warning lamp.

33

Short circuit in the signal cable to the charge indicator lamp.

34

Incorrect signal from the Fixed speed switches.

35

Fault in CAN communication.

1) Single speed engine

2) All-speed engine

1588955

11

Scania Control Panel (SCP)

Start and stop the engine from the Scania Control Panel which has a

starter key and a stop button together with functions for Fixed Speed

and Limp Home.

S42

W19S45 S47

S49

S43

W20

S46

S1

S50

W20

2

1

1.

Master panel

2.

Slave panel

W19

Lamp for Active Panel

W20

Lamp for Limp Home Throttle

S1

Ignition key

S42

Switch for Active Panel function

S43

Switch for activating and switching between Fixed Speed 1 and 2

S45

Switch for storing

S46

Stop button

S47

Switch for adjusting Fixed Speed / idle speed up or down

S49

Switch for deactivating Fixed Speed function

S50

Potentiometer for Limp Home Throttle

Scania Control Panel with ignition key

12

1588955

Following functions are available in Scania Control Panel:

Active Panel

Activate the panel by depressing pushbutton S42. The coordinator

S42

W19

registers that this control position is active and switches on lamp W19.

The panel from which the engine is started is automatically active and

it is then possible to make adjustments and requesting throttle

actuation.

In order to change active panel (changing throttle position) both

throttle controls must be at 0% throttle. Switch off the active panel so

that neither panel is active. Then it is possible to change control

position.

With single instrumentation, the panel is activated when the key is

turned to the ignition position.

If the throttle control fails, the Active Panel lamp is still illuminated

and the Limp Home lamp comes on which means that the limp home

throttle (emergency throttle) is engaged.

If CAN communication fails, the Limp Home lamp comes on and the

Limp Home throttle is engaged.

See also under Limp Home Throttle.

1588955

13

Fixed Speed 1 and 2

These two functions are activated via a 3-position switch, S43. With

Fixed Speed 1 it is possible to set an isochronous speed between high

and low idle speed. With Fixed Speed 2 it is possible to set an

isochronous speed between 450 and 2000 rpm. In both modes, it is

S49

S45

S47

S43

possible to set torque limitation via diagnostic tool or the digital

display.

When activating, the engine goes up or down to the last saved value for

the mode.

It is a prerequisite for activating these modes that the engine is running,

that the panel is active and that the throttle is at 0%.

Change the speed for either modes in the following way:

- Activate the mode to be changed by activating switch S43 to 1 or 2.

- Adjust the speed up or down using switch S47.

- Press Store switch S45 for 3 seconds to save the new values. If you

exit the mode without saving, the engine will resume the latest

speed value that was stored for that mode.

- With dual instrumentation, it is only possible to make adjustments

from the panel that is active.

- In order to deactivate the function, press switch S49 to Off, touch

the accelerator pedal, change panel when using dual

instrumentation, or switch off the engine.

14

1588955

Idle speed adjustment

Adjust the engine idle speed as follows:

1. Activate Store switch S45 for 3 seconds in order to go to

adjustment mode.

S45

S47

2. Adjust the idle speed up or down (+ or -) using switch S47.

3. Save the set value by activating the Store switch for

3 seconds.

- It is also possible to set the engine idle speed using the diagnostic

tool or Scania digital display.

- In order to adjust the idle speed, the coolant temperature must be

higher than 50°C and the engine running at idle.

- The idle speed can be set to between 500 and 1,050 rpm.

Stop

The function stop the engine is available in several places in the

system.

With single instrumentation, the stop button can be located in 2 places:

S46

- In the Remote Control Box (RCB).

- In the Control Panel (S46).

With dual instrumentation, the stop button can be located in 3 places:

- In the Remote Control Box (RCB).

- In both Control Panels (S46).

When one of these buttons is activated COO sends a message to S6 to

stop the engine.

It is also possible to stop the engine by turning the key to O. With dual

instrumentation it is possible that both Control Panels are in ignition

position and both keys must then be turned to O.

Therefore we recommend that the engine is stopped with a stop

button.

1588955

15

Limp Home Throttle

Limp Home Throttle is an emergency function that is activated if the

master coordinator fails or if the master throttle control fails while the

master control panel is active, or if the slave throttle control, slave

coordinator fail while the slave control panel is active or CAN traffic is

W20

not working.

If this happens Limp Home lamp W20 will come on and Limp Home

Throttle will be engaged.

S50

Limp Home Throttle, S50, consists of a potentiometer on the master

Control Panel with which it is possible to drive in limp home mode.

The potentiometer value goes directly to switch A2 on the S6 control

unit.

In order to use Limp Home Throttle the potentiometer must first be

turned to the 0 position before it is activated. The potentiometer is only

on the Master Control Panel. There is a Limp Home lamp on both

panels. If CAN fails, both lamps will come on and Limp Home Throttle

is activated.

The potentiometer is only on the master panel but Limp Home lamp

W20 is on both panels.

If the master control fails when the master panel is active, the lamps on

S1

both panels will come on. If you then change to the slave panel, both

lamps will go off and it is possible to control the engine throttle via the

slave panel.

The same will also apply the other way round.

Start Key

Start the engine by using key S1 on Scania Control Panel. The key

gives U15 signal in the Ignition position and U50 signal in the Start

position.

When the coordinator receives a signal from the key to start, the

coordinator sends a CAN message to the S6 control unit, which in turn

sends a signal to the starter relay that supplies the starter motor with

power and the engine starts.

- If one panel is active, it is only possible to start from that panel.

- If no panel is active, the panel that you use to start the engine will

automatically become active.

The engine stops when the key is turned to the 0 position. In dual

systems, this only applies if the other key is not turned on.

16

1588955