Scania Marine engine. DI13 XPI. Operator’s manual - part 2

Component identification

Component identification

1

2

3

14

15

16

17

18

4

13

19

5

12

20

11

21

6

10

9

8

7

25

24

23

22

13

The illustration shows a normal version of a DI13 engine with heat exchanger. The engine ordered may have

different equipment.

1. Oil filler in rocker cover.

2. Hand pump for fuel.

3. Bleed nipples on fuel filter (2 off).

4. Water separating prefilter for fuel.

5. Fuel filter.

6. Ventilating valve on the high pressure pump.

7. Oil plug.

8. Oil dipstick.

9. Oil filler in cylinder block.

10. Sea water intake.

11. Sea water pump.

12. Engine data plate.

13. Sacrificial anodes (2).

14. Charge air cooler.

15. Holes for draining condensation in charge air cooler (on underside).

16. Expansion tank.

17. Filling coolant.

18. Level glass for checking coolant level.

19. Thermostat.

20. Engine number, stamped into the cylinder block.

21. Oil filter.

22. Centrifugal oil cleaner.

23. Nipple for draining and filling coolant.

24. Heat exchanger.

25. Sea water outlet.

Note: There is a further water separating prefilter for the fuel located between the fuel tank and engine.

16

Starting and running

Starting and running

Starting the engine

Checks before first start

WARNING!

Before the engine is started for the first time, car-

Never use starter gas or similar agents to help

ry out the maintenance items listed under First

start the engine. This can cause an explosion in

start in the maintenance schedule. Check the fol-

the intake manifold and possible injury.

lowing:

Only start the engine in a well ventilated area.

• Oil level.

When the engine is run in an enclosed space,

• Coolant.

there must be effective devices to extract exhaust

• Fuel level.

gases and crankcase gases.

• Fluid level in batteries.

• State of battery charge.

IMPORTANT!

• Condition of the drive belt.

See also Maintenance intervals.

The starter motor must only be cranked twice for

30 seconds at a time. After that, it must rest for at

least 5 minutes before the next attempt to start it.

For environmental reasons the Scania engine has

Checks before running

been developed to be started with a low fuel feed.

Using unnecessarily large amounts of fuel when

Carry out daily maintenance as described in the

starting the engine always results in emissions of

maintenance schedule prior to operation. See

unburnt fuel.

Maintenance intervals.

1. Open the fuel cock if fitted.

2. Disengage the engine.

3. If the engine has a battery master switch:

Switch on the power by means of the battery

master switch.

4. Start the engine.

If the fuel tank has been run dry or if the engine

has not been used for a long time, bleed the fuel

system. See the section Bleeding the fuel system.

17

Starting and running

Starting at low temperatures

Limp home mode

Take the local environmental requirements into

If there is a fault in the normal throttle opening or

account. Use a fuel heater and engine heater to

if CAN communication is interrupted, the fol-

avoid starting problems and white smoke.

lowing emergency operation option is provided:

Scania recommends that an engine heater should

A CAN fault or throttle opening fault in an all-

be used if the engine will be used at temperatures

speed engine (both signal and idling switch):

below -10°C (14°F).

• The throttle opening value is 0% and the en-

A low engine speed and a moderate load on a

gine is running at normal idling speed.

cold engine limits white smoke, gives better

• The throttle opening value is 0% and the en-

combustion and warms up the engine more

gine is running at raised idling speed (750

quickly than warming it up with no load.

rpm) if this function is activated.

Avoid running it longer than necessary at idling

Throttle opening fault, but the idling switch is

speed.

working:

• The throttle opening value can be increased

slowly between 0 and 50% by using the idling

switch.

Running

CAN fault:

Check instruments and warning lamps at regular

• The engine is switched off if the shutdown

intervals.

function is activated.

Engine speed range

Driving at high altitude

The engine operating speed range is between low

When driving at high altitudes engine power is

idling and the nominal engine speed. The nomi-

reduced automatically due to the lower oxygen

nal engine speed is indicated on the engine data

content in the air. It is then not possible to run the

plate. Low idling can be set between 500 and

engine at maximum power.

1,050 rpm.

• ICFNengines may be used at an altitude of up

to 2,000 metres.

• IFN-, Patrol Craft Long- and Patrol Craft

Short engines must not be used at an altitude

of more than 1,000 metres.

• Contact Scania if the operating conditions de-

viate from these.

18

Starting and running

Coolant temperature

• Alarm at the lowest limit value and engine

shutdown at the highest limit value.

IMPORTANT!

• Alarm, torque reduction at the lowest limit

value and engine shutdown at the highest lim-

An excessive coolant temperature can cause en-

it value.

gine damage.

• Alarm at the lowest limit value and engine

shutdown at the highest limit value with the

possibility of engine shutdown override con-

Normal coolant temperature during operation is

trol.

90 to 95°C/194 to 203°F for engines with a heat

• Alarm, torque reduction at the lowest limit

exchanger and 83 to 88°C/181 to 190°F for en-

value and engine shutdown at the highest lim-

gines with keel cooling.

it value, with the possibility of engine shut-

Alarm levels are set in the engine control unit.

down override control.

The default setting for the lowest and highest

limit values for high coolant temperature are

If run for extended periods under an extremely

95°C/203°F and 105°C/221°F respectively.

light load, the engine may have difficulty in

maintaining the coolant temperature. At an in-

The high coolant temperature alarm has the fol-

creased load the coolant temperature rises to the

lowing functions:

normal value.

• Alarm only.

• Alarm and torque reduction at the lowest lim-

it value.

19

Starting and running

Oil pressure

Normal oil pressure during operation is 3-6 bar

(43.5-87 psi). The lowest permitted oil pressure

when idling is 0.7 bar (10.2 psi).

The engine management system issues an alarm

when the oil pressure has been under the limit

value for over 15 seconds, at the following limit

values:

• At an engine speed below 600 rpm and an oil

pressure below 0.7 bar (10.2 psi).

• At an engine speed below 1,200 rpm and an

oil pressure below 1.85 bar (26.8 psi).

• At an engine speed above 2,100 rpm and an

oil pressure below 2.8 bar (40.6 psi).

With engine speeds between these limits, the en-

gine management system issues a low oil pres-

sure alarm at an interpolated value of the two

closest engine speeds above.

The incorrect oil pressure alarm has the follow-

ing functions:

• Alarm only.

• Alarm and torque reduction by 30%.

• Alarm and engine shutdown.

• Alarm and engine shutdown override control.

Note:

High oil pressure (above 6 bar/87 psi) is normal

if the engine is cold when started.

20

Starting and running

Charging indicator lamp

If the lamp comes on during operation: Check

and adjust the alternator drive belt according to

the instructions in the section Checking the drive

belt.

If the charging indicator lamp is still on, this

could be due to an alternator fault or a fault in the

electrical system.

Belt transmission

When the belt transmission is new, it may make

a squeaking noise when running. This noise is

normal and disappears after 50-100 hours of op-

eration. The noise does not affect the service life

of the belt transmission.

21

Starting and running

Engine shutdown

IMPORTANT!

There is risk of the oil boiling and of damage to

the turbocharger if the engine is switched off

without cooling. The power must not be

switched off before the engine has stopped.

Note:

The battery voltage must remain on for a few

seconds after the 15 voltage is switched off so

that the control units can store the values and

switch to standby mode.

10 prohibited engine shutdowns in a row will

cause a torque reduction (70% of fuel quantity).

Reset the engine by switching it off correctly

once.

1. Run the engine without a load for a few min-

utes if it has been run continuously with a

heavy load.

2. Switch off the engine.

22

Starting and running

Checks after running

WARNING!

Secure the starting device or disconnect a battery

cable before working on the engine. If the engine

starts unexpectedly, there is a serious risk of in-

jury.

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are engine

manifolds, turbochargers, oil sumps, as well as

hot coolant and oil in pipes and hoses.

IMPORTANT!

Check the coolant level following the first start.

Top up with coolant as necessary.

1. Check that the power supply has been cut.

2. Top up the fuel tank. Make sure that the filler

cap and the area round the filler opening are

clean to avoid contamination of the fuel.

3. If there is a risk of freezing, the cooling sys-

tem must contain enough glycol. See the sec-

tion Risk of freezing.

4. If the temperature is below 0°C (32°F): Pre-

pare for the next start by connecting the en-

gine heater (if fitted).

23

Maintenance

Maintenance

The maintenance programme covers a number of

points that are divided into the following sec-

tions:

• Lubrication system.

• Air cleaner.

• Cooling system.

• Fuel system.

• Other.

WARNING!

Secure the starting device or disconnect a battery

cable before working on the engine. If the engine

starts unexpectedly, there is a serious risk of in-

jury.

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are engine

manifolds, turbochargers, oil sumps, as well as

hot coolant and oil in pipes and hoses.

IMPORTANT!

On delivery a Scania engine is optimised for its

application. However, regular maintenance is

necessary to

• prevent unplanned stops

• extend the service life of the engine

• maximise the long-term emission perfor-

mance of the engine

• give the best possible operating economy.

24

Maintenance

The maintenance programme includes the fol-

lowing:

• R maintenance: One event when taken into

service.

• S maintenance: Minimum basic maintenance.

• M maintenance: More extensive mainte-

nance.

• L maintenance: Includes nearly all mainte-

nance items in the form.

• XL maintenance: Includes all maintenance

items in the form.

During a period, the sequence is S-M-S-L-S-M-

S-L-S-M-S-XL.

XL

L

L

M

M

M

S

S

S

S

S

S

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

25

Maintenance

Cleaning the engine

WARNING!

Beware of hot washing water. Wear eye protec-

tion, protective clothes and protective gloves.

Environment

Dispose of the washing water in compliance with

relevant national or local regulations.

Clean the engine before maintenance.

Clean the engine with hot water. Also use a de-

greasing agent, if necessary.

Do not spray water on the engine control unit,

which is marked in the illustration.

Clean within the area marked by the line.

26

Maintenance

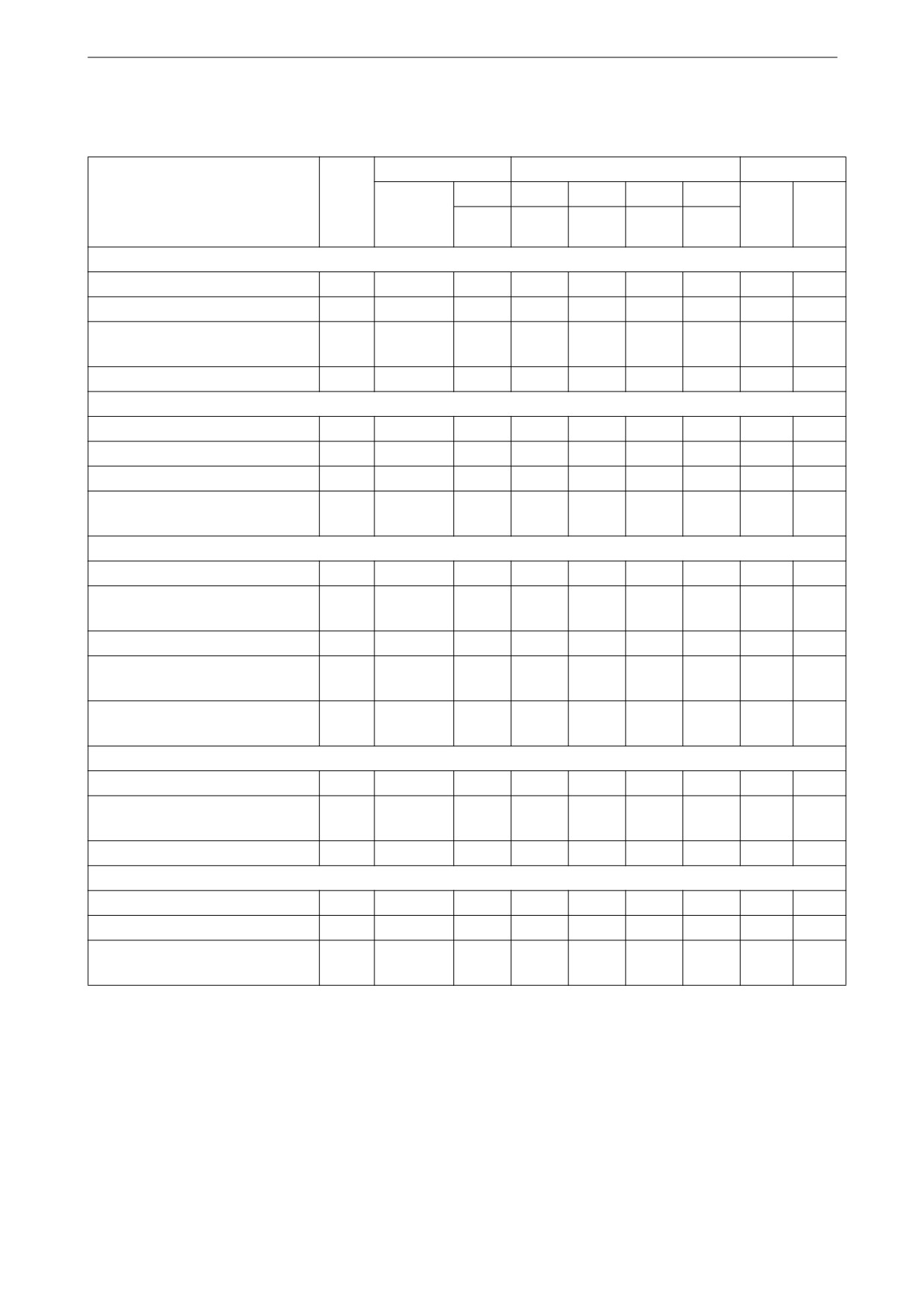

Maintenance intervals

Daily

First time at

Interval (hours)

Minimum

first start

500

500

1,000

2,000

6,000

annu-

every

ally

5

S

M

L

XL

R

years

Lubrication system

Checking the oil level

X

X

Changing the oil

X

X

X

X

X

X

Cleaning the centrifugal oil

X

X

X

X

X

X

cleaner

Renewing the oil filter

X

X

X

X

X

X

Air cleaner

Reading the vacuum indicator

X

X

X

X

X

X

Renewing the filter element

X

X

X

Renewing the safety cartridge

X

X

X

Renewing an air filter with a

X

X

X

non-renewable element

Cooling system

Checking coolant level

X

X

X

X

X

X

X

Checking coolant antifreeze and

X

X

X

X

corrosion protection

Checking sacrificial anodes

X

X

X

X

X

X

Checking the sea water pump

X

X

X

X

X

X

impeller

Changing the coolant and clean-

X

X

ing the cooling system

Fuel system

Checking the fuel level

X

X

Draining the water separating

X

X

X

X

X

X

prefilter

Renewing the fuel filters

X

X

X

X

X

X

Other

Checking the drive belt

X

X

X

X

X

Checking for leaks

X

X

X

X

X

X

Checking and adjusting the

X

X

X

valve clearance

27

Lubrication system

Lubrication system

Oil grade

Scania LDF stands for the Scania Long Drain

Field test standard. Scania LDF oils have been

carefully selected after extensive testing. The ap-

proval is only granted to the highest quality en-

gine oils available on the market.

Recommended engine oil

Scania Oil LDF-3

Scania Oil LDF-2

Scania Oil LDF

Scania Oil E7

The engine oil must fulfil the following quality

requirements:

• ACEA E5/API CI-4.

• ACEA E7/API CI-4 +.

• For engines not run on low-sulphur fuel, the

TBN (Total Base Number) should be at least

12 (ASTM D2896).

• Oils with a low ash content (ACEA E9/API

CJ4) are not recommended.

Check with your oil supplier that the oil meets

these requirements.

If the engine is used in areas of the world where

engine oil with ACEA or API classification is

not available, the oil grade must be measured in

actual operation. In this case, contact the nearest

workshop with qualified personnel.

28

Lubrication system

For operation at extremely low outdoor tempera-

tures: Contact a workshop with qualified person-

nel in order to avoid starting difficulties.

Viscosity

Outdoor temperature in °C

class

SAE 20W-30

-15°C

-

+30°C

SAE 30

-10°C

-

+30°C

SAE 40

-5°C

-

+45°C

SAE 50

0°C

-

+45°C

SAE 5W-30

< -40 °C

-

+30°C

SAE 10W-30

-25°C

-

+30°C

SAE 15W-40

-20°C

-

+45°C

Viscosity

Outdoor temperature in °F

class

SAE 20W-30

5°F

-

86°F

SAE 30

14°F

-

86°F

SAE 40

23°F

-

113°F

SAE 50

32°F

-

113°F

SAE 5W-30

< -40°F

-

86°F

SAE 10W-30

-13°F

-

86°F

SAE 15W-40

-4°F

-

113°F

29

Lubrication system

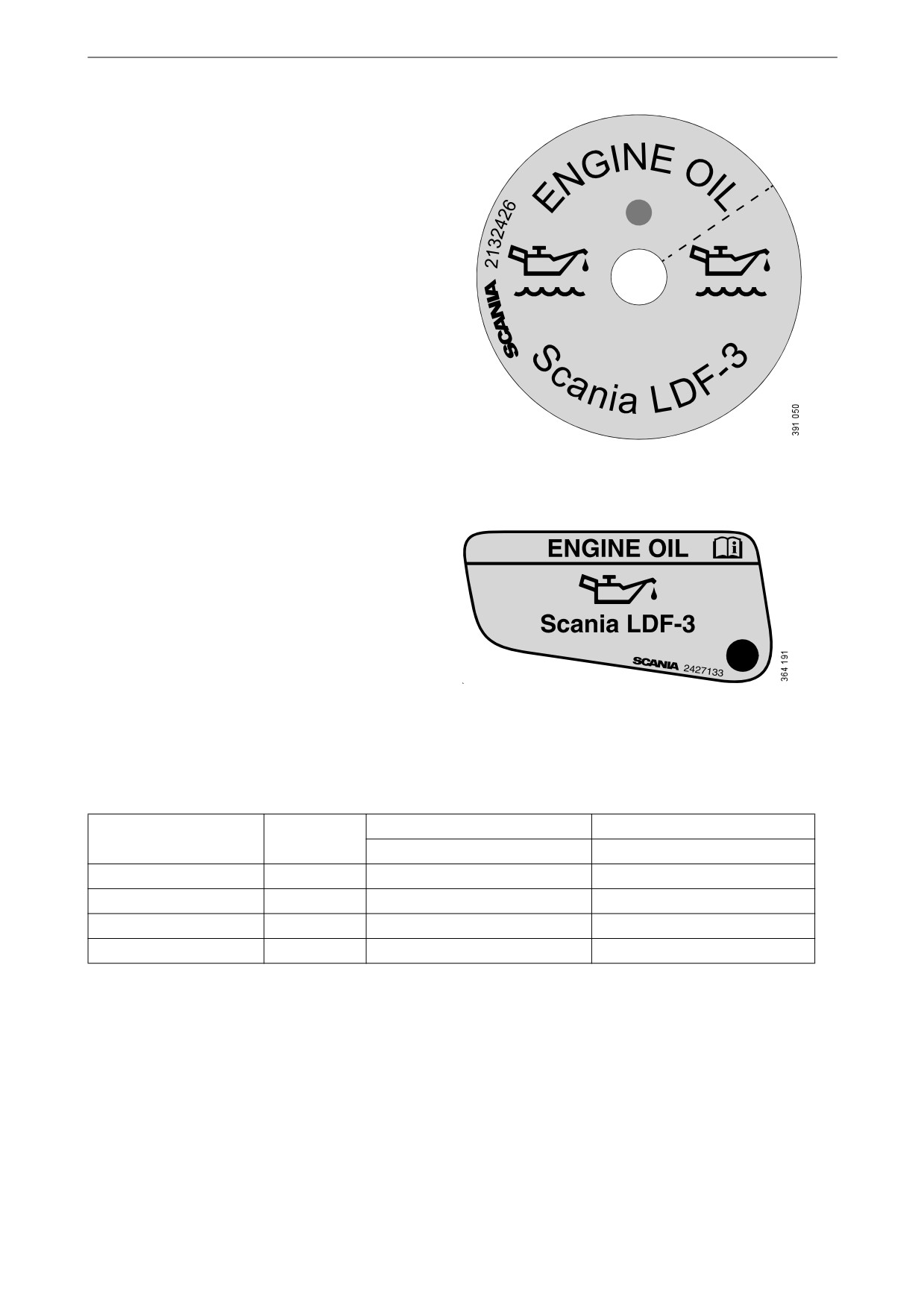

Labels for filled engine oil grade

When changing oil it is important to use the cor-

rect engine oil grade. The oil filler should there-

fore be clearly marked with a label for the filled

oil grade. However, there are only labels for oils

with Scania LDF approval and oil grade

ACEA E7.

Stick on a new label if the oil type or oil grade is

changed in favour of any of the oil types above.

Replace the label if it is missing.

Filling label in the cylinder block.

Filling label in the rocker cover.

If the oil grades below are used, you can order oil

filler labels from Scania.

Oil grade

Colour

Part no.

Part no.

Filling in the cylinder block

Filling in the rocker cover

Scania LDF-3

Red

2 132 426

2 427 133

Scania LDF-2

Blue

2 132 424

-

Scania LDF

Grey

2 269 345

-

ACEA E7

White

2 132 425

2 427 132

30

Lubrication system

Oil analysis

To be able to extend the oil change intervals us-

ing an oil analysis, Scania LDF-3 and LDF-2 oils

must be used. Certain laboratories offer engine

oil analysis.

The following conditions must remain fulfilled

when the oil is changed:

• Viscosity at 100°C (212°F): max. ±20% of

original value of the fresh oil.

• TBN (in accordance with ASTM

D4739):>3.5.

• TBN (in accordance with ASTM D4739): >

TAN (in accordance with ASTM D664).

• Soot (DIN 51452):< 3%.

Such analysis measures the oil's TBN (Total

Base Number), TAN (Total Acid Number), fuel

dilution, water content, viscosity and the quanti-

ty of particles and soot in the oil.

The result of a series of analyses is used as the

basis for establishing a suitable oil change inter-

val.

If the conditions are changed, a new oil analysis

programme must be carried out to establish new

oil change intervals. Work out the new oil

change interval for the engine in conjunction

with the workshop.

REQUIREMENT!

Only Scania LDF oils may be used in conjunc-

tion with oil analysis and a possible extended oil

change interval.

Depending on the market, the warranty condi-

tions may also change if the oil change intervals

differ from the recommended Scania timetable.

31