Scania DC13 XPI. Industrial engine. Operator’s manual - part 7

Miscellaneous

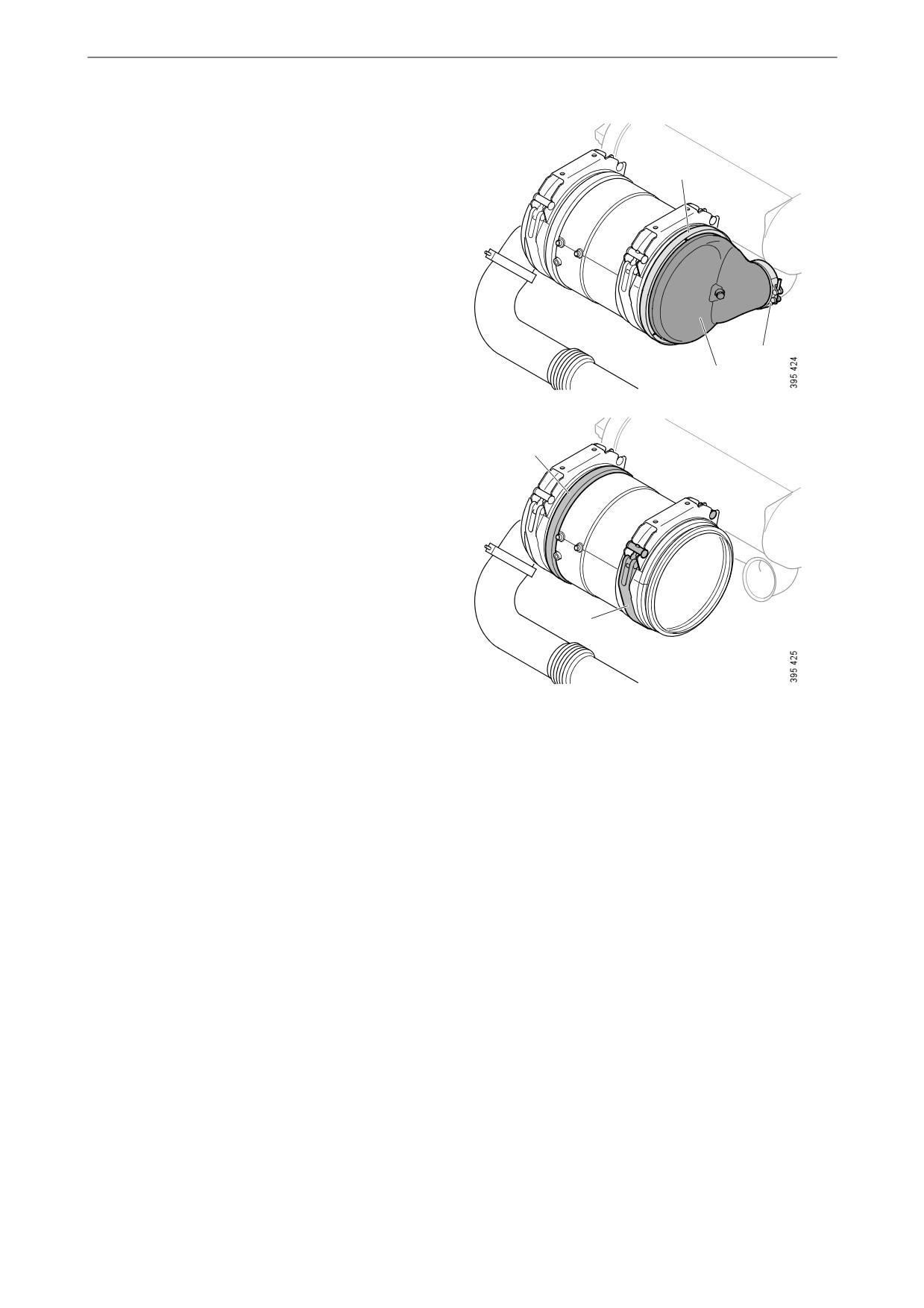

2.

- Remove the V-clamp at the particulate fil-

ter outlet (1)

2

- Remove the V-clamp securing the end

plate (2) and remove the end plate (3)

1

3

2

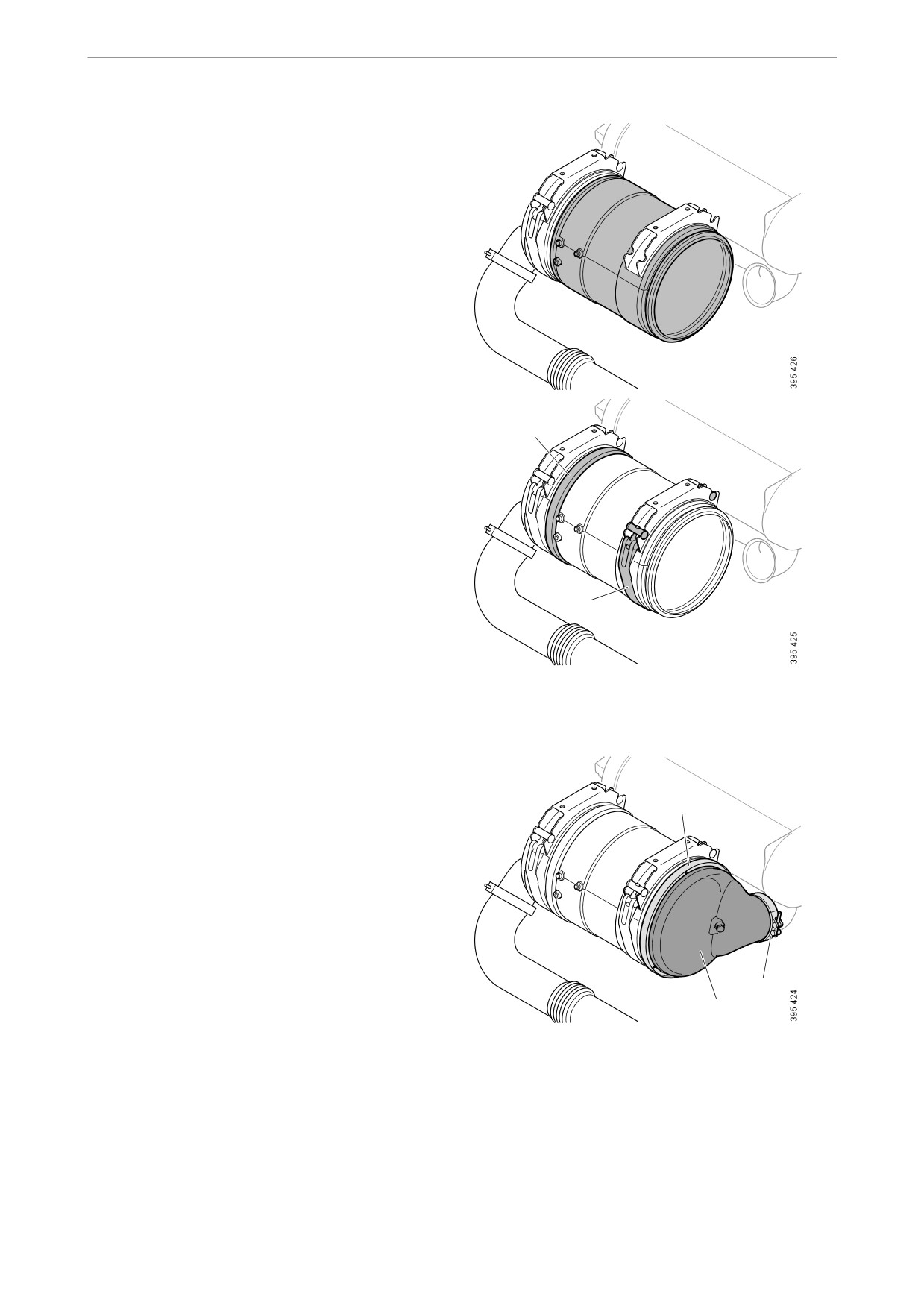

3.

- Support the weight of the particulate filter

using a jack.

- Remove the V-clamp (2) and the band

clamp around the particulate filter (1).

1

96

Miscellaneous

4.

- Carefully lift off the old particulate filter.

- Make a note of the serial number of the

new particulate filter.

- Fit the new particulate filter. Use a jack to

support the particulate filter.

2

5.

- Fit the V-clamp (2) and the band clamp

around the particulate filter (1).

1

2

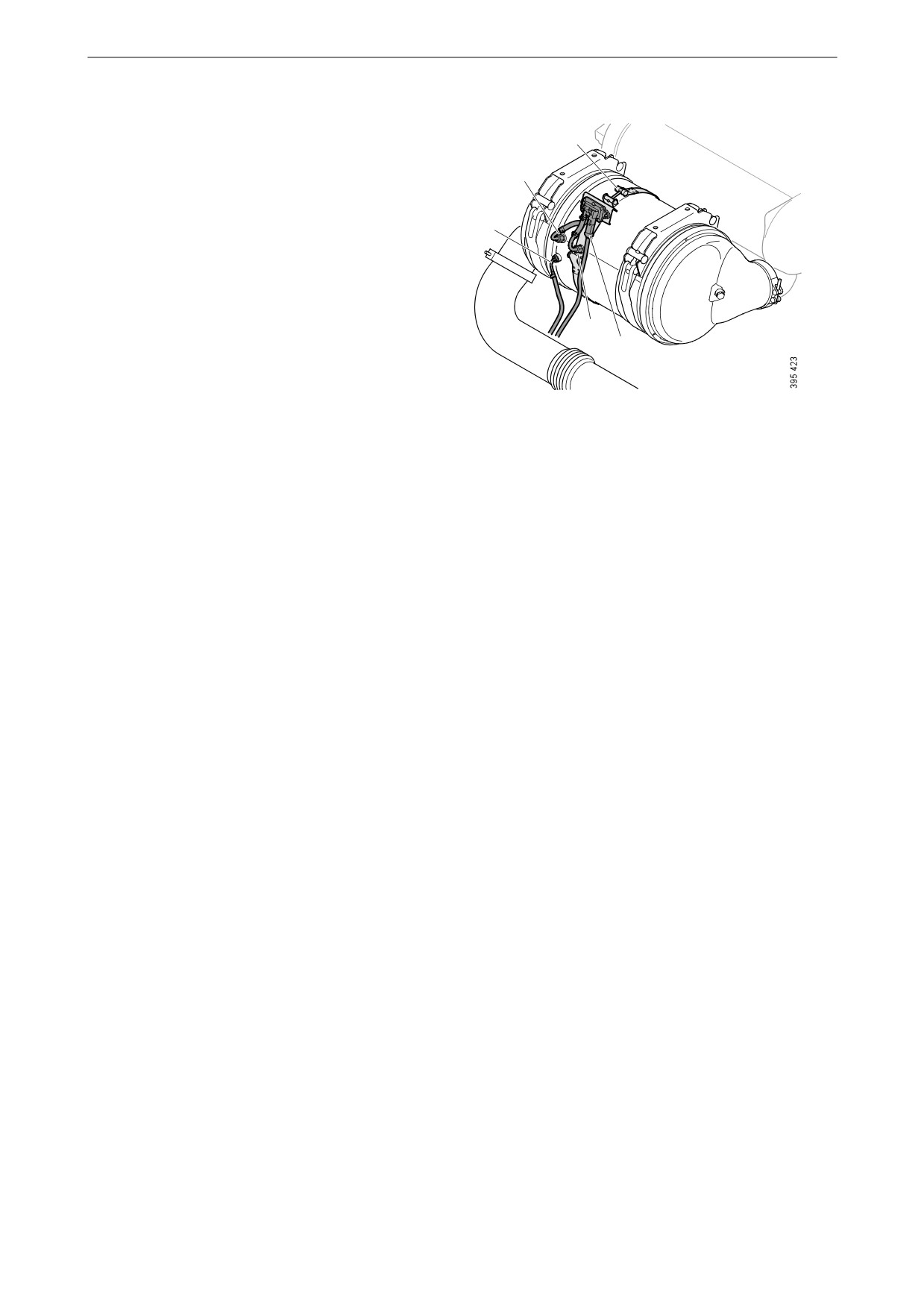

6.

- Fit the end plate (3).

- Fit the V-clamp securing the end plate (2).

- Fit the V-clamp at the particulate filter

outlet (1).

1

3

97

Miscellaneous

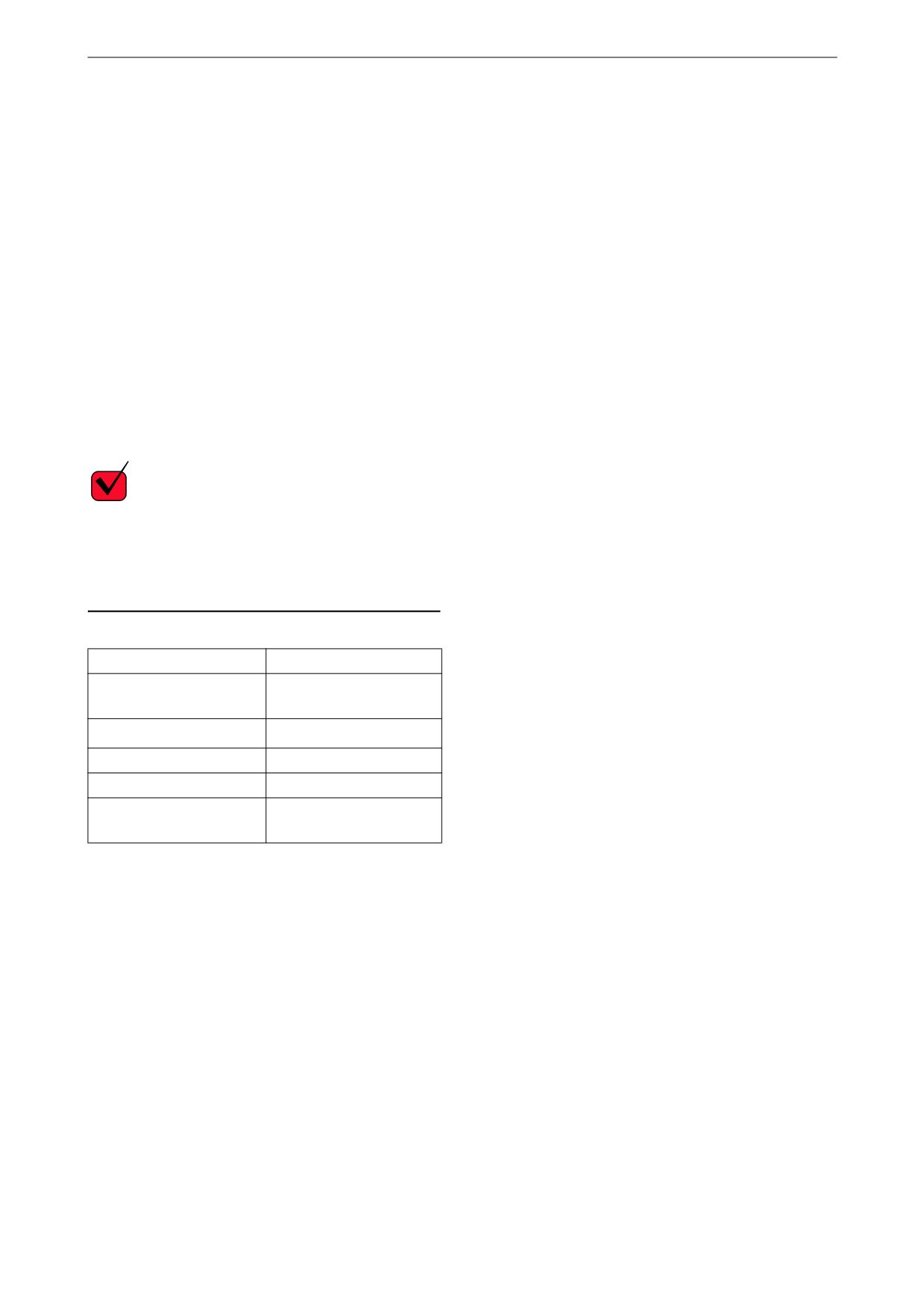

7.

- Fit the bracket with the differential pres-

4

sure sensor.

2

- Fit the differential pressure sensor connec-

tions to the particulate filter (2).

– Fit the temperature sensor (1) and connect

1

the differential pressure sensor harness-to-

component connector (3).

2

3

98

Quality requirements for fuel

Quality requirements for

fuel

Quality requirements and testing standards for

the most important properties of different types

of fuel are described in the Workshop Manual.

This can be ordered from Scania dealers or di-

rectly from Scania.

Diesel

Properties

The quality of the diesel is very important for the

operation and service life of the engine and the

fuel system, and also for the engine performance.

REQUIREMENT!

The diesel should comply with the requirements

of European standard EN590.

However, Scania accepts larger tolerances of

certain properties. Please see the table below.

Property

Requirement

Viscosity at 40°C

1.4-4.5 cSt

(104°F)

Density at 15°C (59°F)

0.77-0.87 kg/dm3

Ignitability (CET rating)

minimum 49

Lowest flashpoint

56°C (132°F)

Particulate contamina-

Classification 22/20/17

tion level

according to ISO 4406

99

Quality requirements for fuel

Sulphur content

IMPORTANT!

The operator is responsible for using the correct

type of diesel to ensure that local laws are com-

plied with.

Important to use low sulphur diesel

It is important for sulphur-free or ultra-low sul-

phur diesel to be used on engines with SCR sys-

tems certified in accordance with Stage III B/

Tier 4i or later to ensure that the engine operates

correctly. If diesel with an excessive sulphur

content is used, it can cause damage to the engine

and the SCR system.

From January 2011 legislation in the USA and

Europe requires all diesel engines not used on the

road to be run on sulphur-free or ultra-low sul-

phur diesel.

REQUIREMENT!

In Europe, the diesel should be sulphur-free ac-

cording to standard EN 590. This means that the

sulphur content must not exceed 10 ppm.

In the USA, the diesel must be ultra-low sulphur

in accordance with the ASTM D975 standard.

This means that the sulphur content must not ex-

ceed 15 ppm.

100

Quality requirements for fuel

Permitted sulphur content in diesel

Engine type

Max. sulphur content

Note

Engines without EGR and SCR

4,000 ppm (0.4%)

If the sulphur content is higher than

systems

2,000 ppm, the oil change intervals

must be halved. A higher sulphur

content than 4,000 ppm is not per-

mitted, since this will result in en-

gine damage.

Engines with SCR system only

500 ppm (0.05%)

A higher sulphur content than

10 ppm for Europe or 15 ppm for

the USA may only be used where

Stage III A/Tier 3 or less restrictive

emission laws apply.

Engines with both EGR and SCR

350 ppm (0.035%)

A higher sulphur content than

systems

10 ppm for Europe or 15 ppm for

the USA may only be used where

Stage III A/Tier 3 or less restrictive

emission laws apply.

Diesel with a higher sulphur content than

500 ppm for engines with SCR systems

If diesel with a higher sulphur content than per-

mitted is used on a short-term basis, this will not

cause permanent damage to the SCR catalytic

converter. The SCR catalytic converter may,

however, require diesel with a low sulphur con-

tent for some time after this to regain its normal

efficiency.

If diesel with too high a sulphur content is used

for a prolonged period, there is a risk that the

SCR catalytic converter will not operate correct-

ly, which will result in a reduction in engine

torque.

101

Quality requirements for fuel

Temperature dependence of diesel

IMPORTANT!

Mixing kerosene or other paraffins with the die-

sel is prohibited. The injectors may be damaged.

It is not permissible to mix petrol with diesel. In

the long term petrol can cause wear in the injec-

tors and engine.

At temperatures lower than those specified for

the diesel, paraffin wax may precipitate from the

diesel and block filters and pipes. The engine can

then lose power or stop.

The diesel is adapted for use in the specific cli-

mate of each country. If an engine is to be oper-

ated in a temperature zone with a temperature

lower than normal, first identify the temperature

properties of that particular diesel.

HVO

HVO is a synthetic diesel which is manufactured

through the hydrogenation of plants and animal

fats. To the user, HVO is reminiscent of diesel in

accordance with EN590, apart from HVO having

a somewhat lower density.

Scania approves the use of up to 100% HVO for

all engines in accordance with the European

standard EN 15940.

102

Quality requirements for fuel

Biodiesel (FAME)

Use of biodiesel

IMPORTANT!

For engines with SCR systems, a maximum of

10% mixture of biodiesel should be used.

Scania uses the term biodiesel to refer to a re-

newable diesel made from greases or oils and

methanol. The biodiesel should conform to the

requirements of European standard EN 14214 or

Brazilian standard ANP-45. For biodiesel in ac-

cordance with EN 14214 or ANP-45, the generic

term FAME is frequently used.

Normal diesel in accordance with EN 590 can

contain up to 7% biodiesel from the diesel sup-

plier. There are grades of diesel that comply with

EN 590 but contain a higher mixture of biodies-

el.

Scania approves up to a 10% mixture of biodies-

el for all engines.

103

Quality requirements for fuel

Storage of biodiesel

IMPORTANT!

Biodiesel must not be stored for more than 6

months.

Biodiesel has a maximum storage life of

6 months from the date of production to the ex-

piry date. Biodiesel is affected by light, temper-

ature, water, etc. during storage, which affects

the characteristics and durability of the biodiesel.

Biodiesel also has lower stability against oxida-

tion than diesel. This can result in a thickening of

the biodiesel and blocking of parts of the fuel

system, e.g. the fuel filter. Bacterial growth can

occur when fuel is stored in tanks under unfa-

vourable conditions. Avoid storage in barrels or

auxiliary tanks, except when fuel turnover rates

are high. Check tank cleanliness whenever refu-

elling takes place.

If the engine has been refuelled with biodiesel,

and is stationary for a long period, condensation

water can form in the fuel tank resulting in bac-

terial growth.

See also the section Preservative fuel.

104

Reductant for SCR

Reductant for SCR

IMPORTANT!

The operator is responsible for using the correct

type of reductant to ensure that local laws are

complied with.

REQUIREMENT!

In order for the emission control to meet the

emission requirements set by the public authori-

ties, the reductant should be specified in accord-

ance with ISO 22241.

Reductant is a solution consisting of urea and

water, and is usually called AdBlue®, DEF,

ARLA 32 eller AUS 32, depending on the mar-

ket. If the engine is equipped with an SCR sys-

tem, the reductant is added to the exhaust gases

upstream of the catalytic converter. This reduces

nitrogen oxide emissions.

Reductant in accordance with ISO 22241 con-

tains 32.5% by weight of urea and freezes at ap-

proximately -11°C (12°F). When the solution

freezes, ice and urea always maintain the same

concentration. Always store reductant at a tem-

perature between -11°C and 30°C (12-86°F).

Rec. % by weight of

Limit values according

urea

to ISO 22241

32.5%

31.8-33.2%

105

Reductant for SCR

Reductant is normally colourless if no dye has

been added. It is not harmful to the skin. Nor is it

toxic in small quantities, but it tastes very un-

pleasant.

Reductant is highly corrosive. Therefore, rinse

any reductant spillage from connections and oth-

er details using lukewarm water. Water works

very well for cleaning purposes. Please use hot

water. If reductant seeps into electrical connec-

tions or electrical cables, these must be renewed.

Reductant has a low surface tension and rapidly

spreads over large areas, which then become

very slippery.

Reductant can dry out and form white or greyish

brown crystals or deposits that can be washed

away with warm water.

The risk of crystal formation increases with low

outdoor temperatures. When the outdoor temper-

ature is below -20°C (-4°F), reductant dosing is

switched off to avoid the risk of crystals forming

in the SCR system.

106

Preparing the engine for storage

Preparing the engine for

storage

If the engine is not being used for an extended

period its cooling system, fuel system and com-

bustion chamber and outside must be protected

against rust.

The engine can normally stand idle for up to

6 months without needing preparation. For

longer periods of than 6 months, however, the

measures in the following sections must be tak-

en. These measures provide protection for ap-

proximately 3 years, then the preparing

procedure must be repeated. An alternative to

preparing the engine for long-term storage is to

start the engine and warm it up every 6 months.

Preparation means that the following measures

are taken:

• The engine is cleaned thoroughly.

• Run the engine for a specific period using

special preservative fuel, oil and coolant.

• Otherwise prepare the engine for storage (fil-

ter renewal, lubrication, etc.).

Preservative products

Preservative oil

Use a normal engine oil that meets the require-

ments in the Oil grade section.

Preservative coolant

Use coolant containing 50% by volume of gly-

col. Example: BASF MPG Glysacorr P113 and

Valvoline Zerex P113 FP.

WARNING!

Ethylene glycol can be fatal if ingested and can

cause skin irritation and eye damage.

107

Preparing the engine for storage

Preservative fuel

Preservative fuel must not contain biodiesel.

Even small amounts of 5-10% biodiesel can have

adverse effects on the engine when in long-term

storage.

Long-term storage of diesel, where the diesel

comes into contact with water, may lead to the

growth of micro organisms (bacteria and fun-

gus).

In order to minimise the growth of micro-organ-

isms, preservative fuel should contain the fol-

lowing additives. The additives should be

selected and added by the fuel supplier.

Preservative fuel should comply with the follow-

ing requirements:

•

0% biodiesel.

•

Max. sulphur content 50 ppm.

•

Max. water content 200 ppm.

•

The fuel must contain additives to stop the

growth of micro-organisms.

Reductant

Over time, the water in the reductant evaporates

and there is only urea left. The reductant then be-

gins to crystallise. The reductant tank is not sen-

sitive to crystals, but the ball valves in the

reductant pump may become clogged. However,

note that corrosion or other particles can also

clog the ball valves.

So that the water in the reductant does not evap-

orate, all connections in the SCR system must be

closed before storage. The SCR system should

then be stored in a cool location and not in direct

sunlight. If the reductant tank has never been

filled with reductant, it can be stored when emp-

ty for an unlimited time.

When the engine is taken into operation again,

all reductant must be drained and changed. If old

reductant is used, the SCR system will not work.

108

Preparing the engine for storage

Preparations for storage

Environment

Use a suitable container. Used oil, coolant and

reductant must be disposed of as specified in na-

tional and international laws and regulations.

Note:

Do not remove the injectors.

1. Remove plugs and tape from the coolant

connections, air intake and exhaust pipe.

2. Drain the oil.

3. Renew the oil filter and fuel filter.

4. Clean the centrifugal oil cleaner.

5. Fill with engine oil to the minimum level on

the oil dipstick.

6. Drain and flush the cooling system of any old

coolant.

7. Top up with preservative coolant.

8. Mix preservative fuel in a can. Detach the

fuel pipe at the feed pump suction line and

connect a hose from the can.

109

Preparing the engine for storage

9. Detach the fuel pipe at the overflow valve

and connect a return hose to a separate can.

10. Connect and bleed the fuel system.

11. Start the engine and run it at about 1,100 rpm

for 20 minutes.

If the engine has an SCR system and the re-

ductant tank is empty, it is possible to run the

engine for this limited time without damag-

ing the components of the SCR system. This

applies if the engine is run without load.

12. If the engine has an SCR system and the re-

ductant tank is full of reductant: Seal all con-

nections in the SCR system.

13. Remove the rocker covers and lubricate the

valve mechanisms with pushrods and the

valve tappets, as well as the injector mecha-

nism, using a liberal amount of preservative

oil. Refit the rocker covers.

14. Drain the coolant if the engine is not to be

stored with coolant in the system. Plug and

tape all coolant connections if the engine is

to be stored without coolant in the cooling

system.

15. Renew the filter element in the air cleaner.

16. Cover the air intake and exhaust pipe.

17. Spray the outside of the alternator and starter

motor with water-repellent anti-corrosive

oil: CRC 226, LPS1 or equivalent.

18. Spray the outside of bright engine parts, first

with penetrating preservative oil such as

Dinitrol 25B and then with Dinitrol 112 or

the equivalent.

19. Clearly mark the engine with the storage

preparation date, and state that the engine

must not be started or cranked.

110

Preparing the engine for storage

Batteries

WARNING!

Wear protective gloves and protective goggles

when charging and handling batteries. The bat-

teries contain a highly corrosive acid.

Remove the batteries and trickle charge them at

the battery charging station. This does not apply

to batteries specified as maintenance-free by the

manufacturer.

The same applies to short-term storage, even if

the engine has not been prepared for storage as

above.

Storage

After the preparation, the engine should be

stored indoors in a dry location at room temper-

ature. The engine must be packed in packaging

made of VCI plastic to protect against dust, dirt

and moisture.

111