Scania DI14 69 (750 hp), DI14 82 (800 hp). Marine engine. Operator’s manual - part 3

8. Every 400 hours:

CHECKING COOLANT

Coolant should be checked as follows:

a) Check the appearance of the coolant.

b) Coolant with glycol: Check the glycol content.

c) Coolant with Scania Anti-corrosive:

Coolant composition:

Check the corrosion protection.

If there is a danger of freezing:

The composition of the coolant is also described under

at least 30% glycol by volume

“Starting and running”.

max. 50% glycol by volume

a)

If there is no danger of

Checking the appearance of the coolant

freezing:

- Take a little coolant in a vessel and check that it is clean and clear.

7-12% by volume

- If the coolant is contaminated or cloudy: Consider changing the coolant

Scania Anti-corrosive

- The water for the coolant should be free of dirt.

- Use drinking water with a pH of 6 - 9.

b)

Checking glycol content

If there is a danger of freezing, use only glycol as protection against corrosion

Ethylene glycol is highly

in the coolant.

dangerous if ingested and can

- Cooling systems with glycol must contain at least 30% glycol by vol-

prove fatal.

ume to offer sufficient protection against corrosion.

Avoid skin contact with glycol.

-

30% glycol by volume provides anti-freeze protection down to -16 °C.

If more protection is required, see the table on the next page for calculat-

ing the necessary amount of glycol.

We recommend only nitrite-free glycol anti-freeze with the following sup-

plier designations:

The coolant should be ready

BASF G48 or BASF D542

mixed when it is poured into the

- Top up with glycol if the glycol content is less than 30% by volume. A

cooling system.

glycol content greater than 50% by volume will not provide more anti-

Never top up with only water or

freeze protection.

only glycol.

- The table shows the temperature at which ice (slush) starts to form. The

engine freezes and breaks at significantly lower temperatures, see graph.

- Ice forming in the coolant often causes malfunction without any risk of

damage. The engine must not be loaded hard when ice is forming.

Note: The coolant should be changed when the cooling system is

The recommended glycol must

cleaned: every 1,200 hours or at least every 3rd year.

not be mixed with glycol having

nitrite-based anti-corrosive.

Important: If a coolant filter is used in the cooling system, it must not

Risk for build up of sludge and

contain an inhibitor.

reduced cooling capacity.

32

2001-05:1

% glycol by volume

Properties of glycol at low temperatures:

- Example with 30% glycol by volume

- Ice slush starts to form at -16°C.

- There is risk for malfunctions at -30°C

No risk of damage by freezing with a minimum

content of 30% glycol by volume

Curve A: Ice build up starts (slush)

Curve B: Temperature at which damage due to

freezing can occur

1. Safe range

2. Malfunctions may occur (ice slush)

3. Risk of damage by freezing

A

% glycol by

15

20

25

30

35

40

45

50

60

Cooling

volume

system

Ice slush starts

capacity, dm3

-6

-9

-12

-16

-22

-27

-36

-46

-55

to form at °C

5

6

8

9

11

12

14

15

18

30

6

8

10

12

14

16

18

20

24

40

8

10

13

15

18

20

23

25

30

50

9

12

15

18

21

24

27

30

36

60

11

14

18

21

25

28

32

35

42

70

12

16

20

24

28

32

36

40

48

80

14

18

23

27

32

36

41

45

54

90

15

20

25

30

35

40

45

50

60

100

Glycol dm3

17

22

28

33

39

44

50

55

66

110

(litres)

18

24

30

36

42

48

54

60

72

120

20

26

33

39

46

52

59

65

78

130

21

28

35

42

49

56

63

70

84

140

23

30

38

45

53

60

68

75

90

150

24

32

40

48

56

64

72

80

96

160

26

34

43

51

60

68

77

85

102

170

27

36

45

54

63

72

81

90

108

180

29

38

48

57

67

76

86

95

114

190

30

40

50

60

70

80

90

100

120

200

A = Range to be avoided. Only for calculation of glycol mix.

Freezing point of coolant when ice slush starts to form at different glycol mixes

2001-05:1

33

b)

Checking Protection against corrosion

There must always be sufficient anti-corrosive (inhibitor) in the coolant to

Corrosion inhibitor, if

protect the cooling system against corrosion.

swallowed can be fatal.

If there is no danger of freezing use only Scania Anti-corrosive.

Avoid contact with the skin.

The inhibitor in Scania Anti-corrosive is nitrite-free.

The correct level of anti-corrosive is 7-12% by volume.

- Fill with Scania Anti-corrosive as indicated on the packaging.

- Topping up with 1.0% by volume of Scania Anti-corrosive should be

Mixing corrosion inhibitor with

done after every 400 operating hours.

glycol or adding too much

- Never top up with water only or anti-corrosive only. Lost fluid should

corrosion inhibitor may cause

always be replaced with pre-mixed coolant:

deposits and reduced cooling

water + 10% Scania Anti-corrosive by volume.

capacity.

Note: The coolant should be changed when the cooling system is cleaned:

every 1,200 hours or at least every 3rd year.

If a coolant filter has been fitted

it must not contain inhibitor.

Changing the coolant

1. Remove the filler cap from the expansion tank.

2. The coolant is drained at two points:

- the ”lowest point” of the engine block, see drawing

- the ”lowest point” of the cooling system.

3. Close the drain cocks.

4. Fill coolant through the expansion tank filler hole.

Mix coolant as described on page 32.

Always collect fluid in a suitable

container to avoid spillage when

changing coolant.

Dispose of used coolant through

an authorized waste disposal

contractor.

34

2001-05:1

9. Every 1200 hours:

CLEANING THE COOLING SYSTEM

Note: If necessary, the cooling system should be cleaned more often.

External cleaning

The cooling system must never

Heat exchanger

be cleaned with caustic soda.

1. Drain the coolant from the engine, see “Changing coolant”.

There is a risk of damage to

aluminium parts.

2. Close the bottom valve or valves and drain the seawater circuit.

3. Disconnect the heat exchanger’s seawater pipe connections and the con-

nections to the charge air coolers, oil cooler and block.

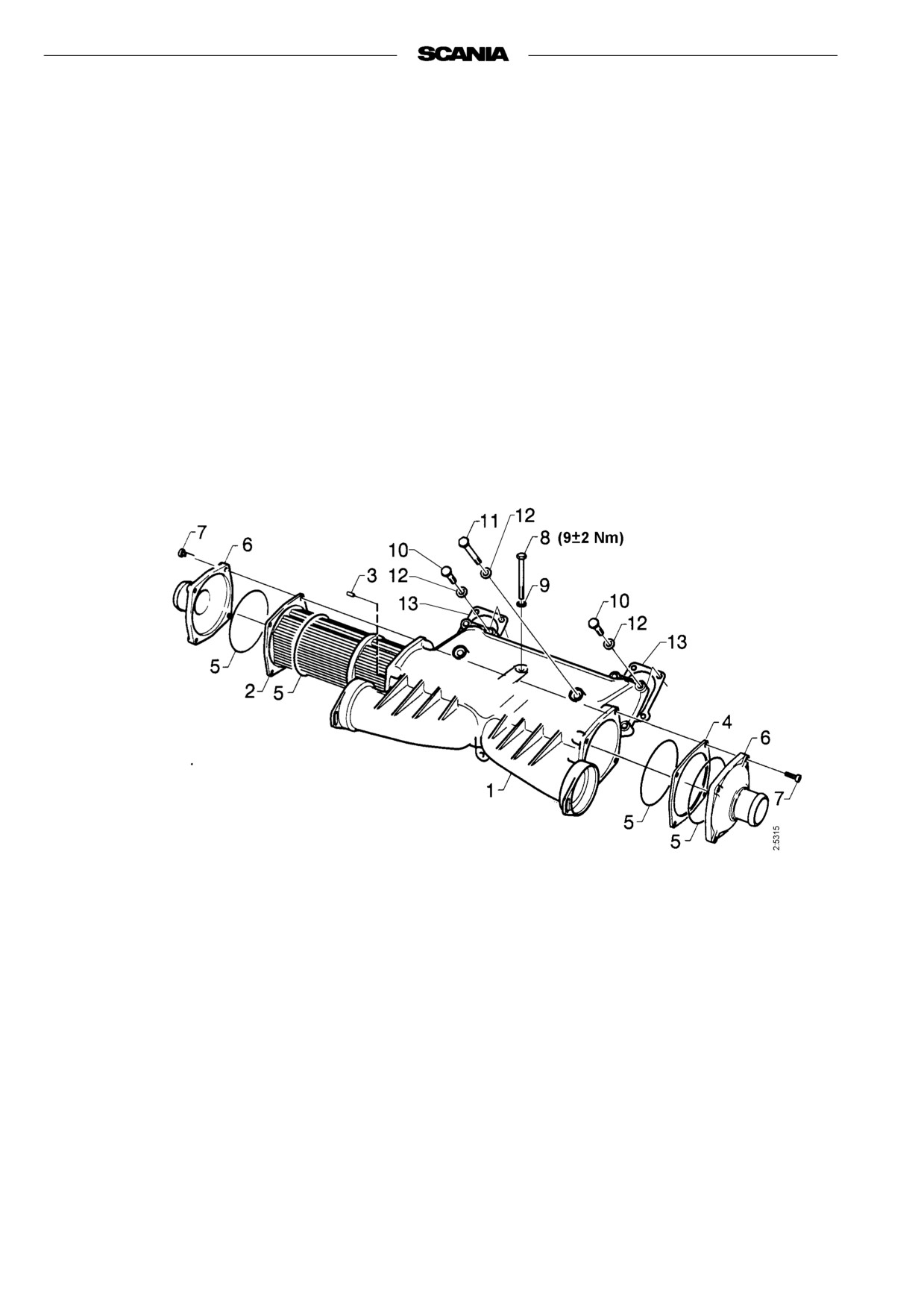

4. Remove the heat exchanger assembly and dismantle it as illustrated.

5. Clean the outside of the element. Use a paraffin-based engine cleaner.

There are springs and retainers

6. Remove any deposit on the inside of the pipes using a round file.

in the heat exchanger, between

7. Assemble the heat exchanger. Change damaged and hardened O-rings.

the housing and the element,

which are not illustrated.

8. Make sure that the thermostats are in place and fit the heat exchanger

back in place on the engine. Reconnect the pipes to the charge air cool-

ers and oil cooler and also the return line from the block.

9. Fill the system with coolant as described in the specifications on

page 32.

1. Housing

15. Gasket

2. Spiral pin

16. O-ring

3. Element

17. Bolt

4. O-ring

18. Gasket

5. Gasket

19. Flange pipe

6. Gasket

20. Gasket

7. Cover

21. Bolt

8. Bolt

22. Bolt

9. Washer

23. Plug

10. Cover

24. Washer

11. Bolt

25. Washer

12. O-ring

26. Bolt

13. Plug

27. Bolt

14. Sacrificial anode

2001-05:1

35

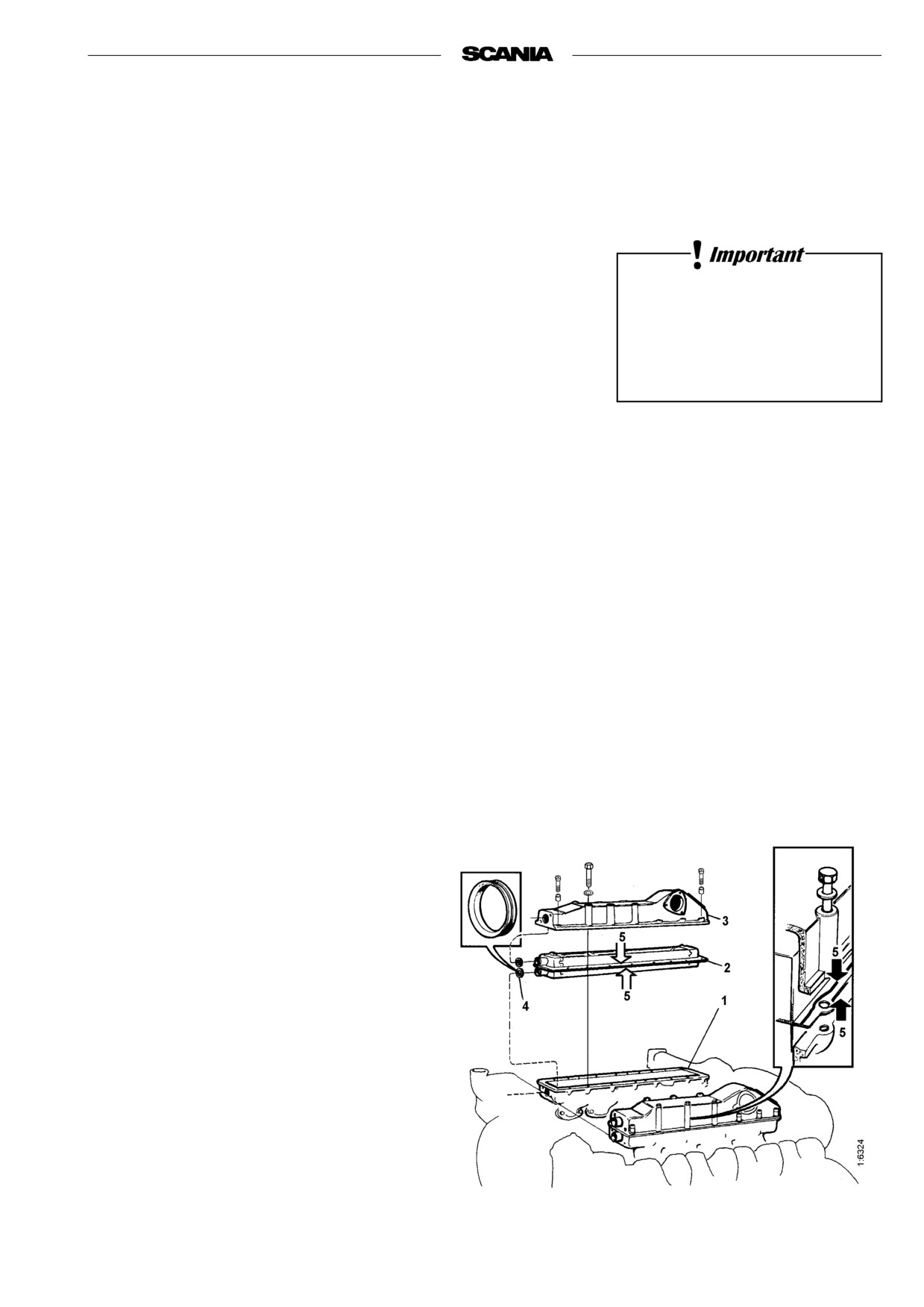

Seawater-cooled charge air cooler

1. Disconnect the connecting pipes for air and seawater and remove the

charge air cooler assembly.

2. Dismantle the charge air cooler as illustrated.

3. Clean the outside of the element. Use a paraffin-based engine cleaner.

4. Remove any deposit on the inside of the pipes using a round file.

5. Assembly the charge air cooler. Change any damaged and hard O-rings.

6. Refit the charge air cooler assembly after the seawater-cooled charge air

coolers have been cleaned and assembled.

Tighten bolt 8 to 9±2 Nm.

Note: On assembly, silicone (816 064) should be applied to both sides of

new gaskets 13.

7. Refit the pipe connections for air and seawater.

1. Housing

8. Bolt

2. Element

9. Washer

3. Spiral pin

10. Bolt

4. Spacer

11. Bolt

5. O-ring

12. Washer

6. Cover

13. Gasket (2)

7. Bolt

36

2001-05:1

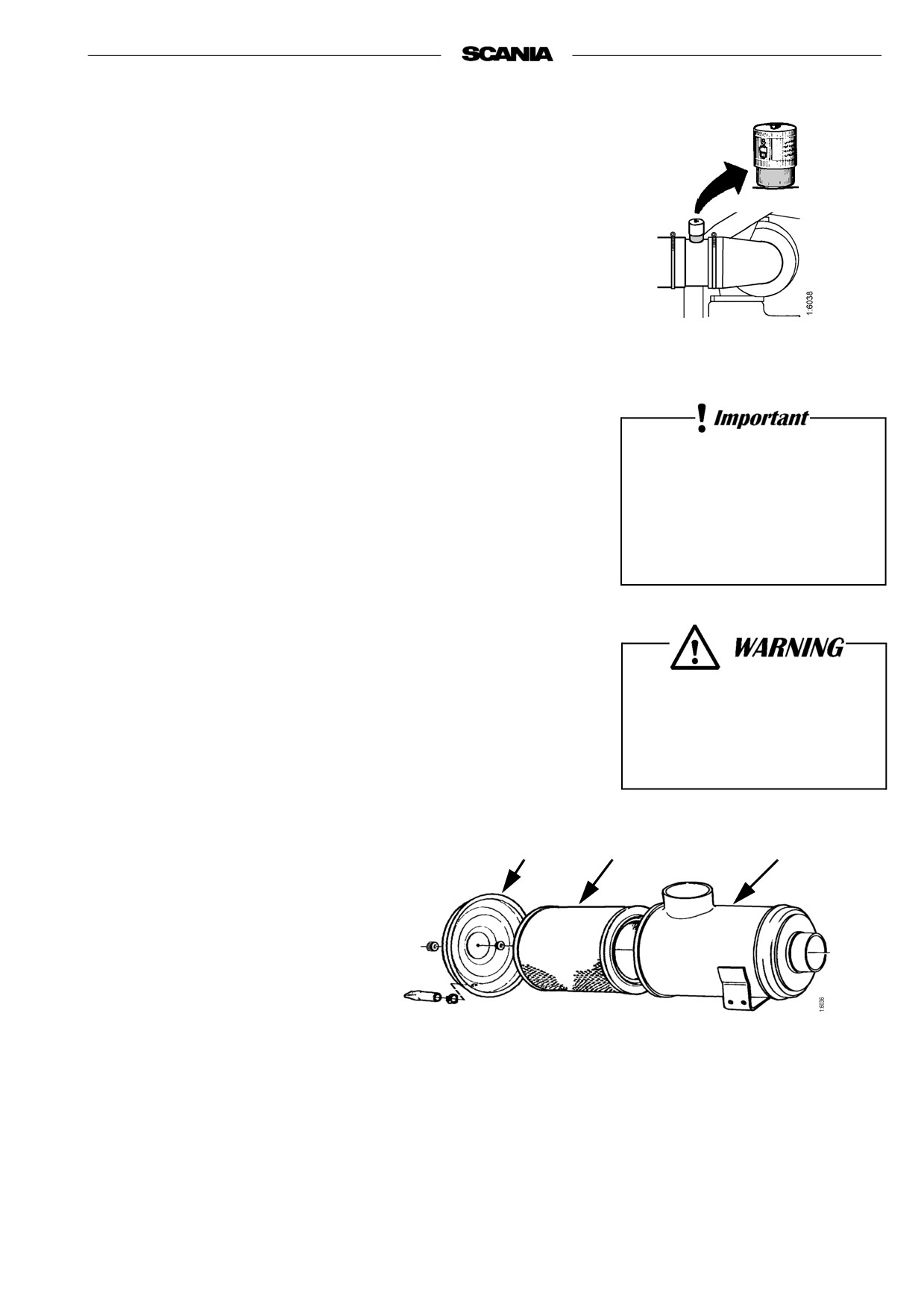

Coolant-cooled charge air cooler

1. Drain the coolant from the engine, see “Changing the coolant”, and

drain the seawater circuit if this has not been done when cleaning the

heat exchanger.

2. Remove the catwalk, delivery pipes, fuel filter and water pipes to the

turbo unit.

3. Remove the rear, transverse charge air cooler (seawater-cooled).

4. Undo the charge air cooler’s inlet and outlet pipe connections.

5. Dismantle the charge air cooler as illustrated.

The cooling system must never

Exercise care - do not damage the element’s water connections.

be cleaned with caustic soda.

6. Clean the outside of the element. Use a paraffin-based engine cleaner.

There is a risk of damage to

7. Clean and degrease the sealing surfaces on the core and the air intake

aluminium parts.

manifold upper and lower parts with a spirit based cleaner.

8. Apply sealant (silicone 816 064) in a uniform bead, approximately

2-3 mm, on both sealing surfaces of the element.

9. Fit new V-ring seals on the connections of the element.

10. Assemble the charge air cooler within 15 minutes of applying the sea-

lant. Torque tighten the bolts to 50 Nm.

11. Reconnect the inlet and outlet pipe connections and refit the delivery

pipe, fuel filter and other parts that have been removed.

12. Refit the transverse charge air cooler and its pipe connections for air and

seawater.

Note: On reassembly, apply silicone to the sealing surfaces against the

seawater-cooled charge air cooler and its gaskets.

13. Fill up with coolant as per the specifications on page 32.

Important Allow the sealant to cure for minimum

24 hours before the engine is used.

1. Intake manifold,

lower part

2. Radiator element

3. Intake manifold,

upper part

4. V-ring seal

5. Sealant 816 064

2001-05:1

37

Internal cleaning

Removing oils and greases

- If possible, run the engine until it is warm and then drain the cooling

system.

- Remove the thermostats. This will necessitate removal of the heat

exchanger assembly. It is therefore advisable to do this in connection

with cleaning the heat exchanger.

- Fill the system with clean, hot water mixed with liquid dishwasher

Handling cleaning agents for

detergent designed for household machines. Mix 1% (0.1/10 l).

the cooling system:

- Warm up the engine for about 20 or 30 minutes. Do not forget the cab

Read the warning label on the

heating system, if any.

container.

- Drain the cooling system.

- Fill the system again using clean, hot water and run the engine for about

20-30 minutes.

- Drain the water from the system.

- Refit the thermostats.

- Fill the system with coolant as described in the specifications on

page 32.

Always collect fluid in a suitable

Removing deposits

container to avoid spillage when

- If possible, run the engine until it is warm and then drain the cooling

draining coolant.

system.

Dispose of used coolant through

- Remove the thermostats. This will necessitate removal of the heat

an authorized waste disposal

exchanger assembly. It is therefore advisable to do this in connection

contractor.

with cleaning the heat exchanger.

- Fill the system with clean, hot water mixed with one of the commer-

cially available radiator cleaners based on sulphamic acid and contain-

ing dispersing agents. Follow the manufacturer’s instructions for mix

ratios and cleaning times.

- Run the engine for the specified time and then drain the cooling system.

- Fill the system again with hot water and run the engine for about 20 or

30 minutes.

- Drain the water from the system.

- Refit the thermostats.

- Fill the system with coolant as described in the specifications on

page 32.

Preventive replacement of coolant pump gear

Note: To be carried out in connection with cleaning of the cooling

system.

- Remove the coolant pump.

- Remove the drive gear.

- Fit a new gear and tighten the nut to 200 Nm.

Note: Do not apply the tightening torque to the gear itself.

- Refit the coolant pump, using new gaskets for the timing gear cover.

38

2001-05:1

AIR CLEANER

10. Daily:

TEST READING

LOW PRESSURE INDICATOR

If the indicator’s red plunger is fully visible, change or clean the air cleaner

filter insert, point 11.

11. Every 1,200 hours:

Only use Scania genuine air

CLEANING OR CHANGING THE

filter. Change the filter element

FILTER INSERT

if it is damaged.

Note: Earlier if low pressure indicator shows red.

Danger of engine damage if the

Dismantling

filter element is damaged.

1. Remove air cleaner’s side cover.

2. Change or clean the insert.

Note: Cleaning the insert always entails a risk of damage. The insert

may be cleaned no more than four times. After cleaning, it has a

lower dust capacity than a new insert.

Never start the engine unless

3. Mark the filter when it has been cleaned.

the air filter is installed.

Danger of personal injury or

Cleaning insert

engine damage.

- Carefully blow the filter insert clean using dry compressed air from the

inside.

Note: This insert must not be washed using water.

1

2

3

1. Cover

2. Filter insert

3. Filter housing

2001-05:1

39

Checking

- Insert a flashlamp into the insert and check from the outside that there

are no holes or cracks in the filter paper.

- Change the filter insert if there is any damage at all. Danger of engine

damage.

Assembly

1. Assemble the air cleaner in reverse order.

2. Reset the red plunger in the low pressure indicator by pressing in the

button.

Filter with non-replaceable insert (unit cleaner)

Cleaning

- The filter must be cleaned no more than 3 times. Make a mark on it each

time it is cleaned.

- Use a washing solution consisting of water mixed with about 1% mild

detergent.

1. Pour the washing solution into the filter outlet while turning the filter so

that the solution runs out of it opposite to the direction of air flow.

2. Leave the filter in the washing solution for 5 minutes and then lift it to

drain off the solution.

3. Rinse the filter with about 30 litres of clean water at 30 - 40 °C. Pour the

rinse water into the filter in the same way as the washing solution.

4. Lift the filter and allow the rinse water to drain.

5. Repeat this procedure until the rinse water runs clear.

6. Leave the filter to dry in a warm place for a day or so.

Note: The filter must not be blown dry using compressed air.

40

2001-05:1

FUEL SYSTEM

Be extremely careful with

12. Daily:

cleanliness when working on

the fuel system.

CHECKING THE FUEL LEVEL

Malfunctions

- Top up fuel if necessary.

can easily arise and the

- If the tank is run dry, bleed the fuel system, see point 13.

injection equipment

can be damaged.

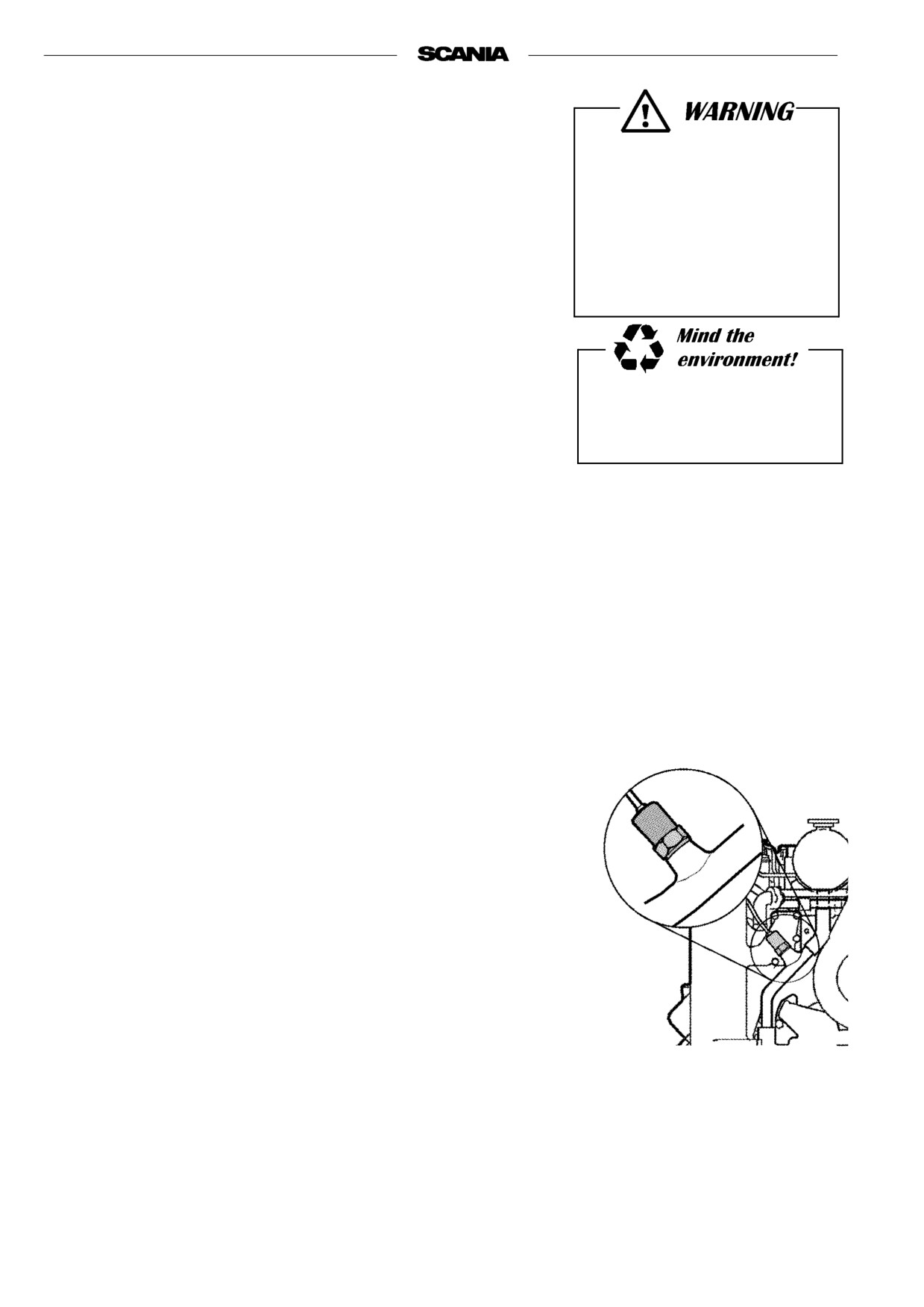

13. Every 1200 hours:

CHANGING THE FUEL FILTER

Fuel tanks

- Drain any water from the fuel tanks.

Filter

The filter consists of two filter units connected in parallel.

- Wash the outside of the filters and unscrew them. Dispose of the filters

according to environmental regulations.

- Tighten the new filters by hand.

Never use tools. The filters may be damaged, inhibiting circulation.

- Bleed the fuel system as described below.

- Start the engine and check for leaks.

Bleeding the fuel system

- Open bleed screw 1 on the main filter.

Only use Scania genuine fuel

filter.

- Pump hand pump 2 until air-free fuel flows out at the main bleed screw.

- Close the bleed screw. Pump a few times using the hand pump.

If the engine is difficult to start after bleeding

- Slacken injection pump overflow valve 3 half a turn

Always collect fuel in a suitable

and make a fresh attempt to start.

container to avoid spillage when

If the engine still won’t start

bleeding system or renewing

- Pump the hand pump until bubble-free fuel flows from the overflow

components.

valve.

Tighten the overflow valve when the engine has started.

2

3

2001-05:1

41

14. Every 1,200 hours:

1. Socket nut

CHECKING INJECTORS

2. O-ring

Injectors should be inspected by trained personnel with access to the required

3. O-ring

equipment, at least once every year or every 2,400 hours.

4. Stop ring

Removal

5. Guide pin

1. Clean around the injectors and connections including clamps and

6. Seal

brackets.

2. Undo the leak-off pipes and bunch of delivery pipes. Be careful to

avoid bending any of the delivery pipes.

3. Unscrew the injector.

4. Place protective plugs on the injector and delivery pipe.

5. Lift the seal from the bottom of the injector seat if it does not come out

together with the injector.

The delivery pipes must

6. Place a seal plug in the injector seat in the cylinder head.

not be bent.

7. Clean the injectors and check/adjust in an injector tester.

All clamps must be refitted.

Correct opening pressure, see Technical data, page 52.

Fitting

1. Check that there is no old seal in place and fit a new seal in the bottom

of the injector seat.

Always wear gloves and eye

2. Fit a new O-ring in the socket nut and a new seal under it.

protection when testing

3. Fit the injector.

injectors.

4. Tighten the socket nut to 70 Nm (7.0 kgfm).

Fuel escaping under high

5. Fit the delivery pipe and tighten the cap nuts to 20 Nm (2.0 kgfm).

pressure can penetrate body

Fit clamps and brackets.

tissue and cause serious injury.

Take care to fit the delivery pipe without tension and make sure that

the cone on the delivery pipe is correctly positioned in the connection.

6. Fit the leak-off fuel line. Tighten the bolts to 11 Nm (1.1 kgfm).

1. Delivery pipes

2. Cap nut

3. Washer

4. Cone

5. Connection on injector or

injection pump

Delivery pipe connection

42

2001-05:1

ELECTRICAL SYSTEM

15. Every 200 hours:

Do not let open flame or sparks

CHECKING THE ELECTROLYTE

come near the batteries.

LEVEL IN BATTERIES

When batteries are charged,

they emit highly flammable

1. Unscrew the plugs and check the electrolyte level in all cells.

fumes that can explode.

2. Top up with distilled water until the level is 10-15 mm above the plates.

16. Every 200 hours:

CHECKING THE CHARGE STATE

OF THE BATTERIES

- Check the specific gravity using a hydrometer (battery electrolyte

tester).

Wear gloves and eye protection

In a fully charged battery it should be:

when charging and

1.280 at +20 °C

handling batteries.

1.294 at 0°

Batteries contain a highly

corrosive acid.

1.308 at -20 °C

- If the specific gravity is below 1.20, the battery must be charged.

A discharged battery freezes at -5 °C.

- Trickle charging is recommended during the winter if the engine is not

used.

Avoid boost charging. This will damage the battery in the long term.

17. Every 200 hours:

Do not connect the cables to the

wrong terminals.

CLEANING BATTERIES

This could cause serious

1. Clean batteries, cables and cable terminals.

damage to the electrical system.

2. Check that all cable terminals are well tightened.

If the terminals are

shortcircuited, sparks

3. Grease posts and cable terminals using petroleum jelly.

will be generated.

2001-05:1

43

CHANGING BATTERY

Removal

Do not connect the cables to the

1. Detach the negative lead (-) from the battery (cable to engine casing).

wrong terminals.

2. Detach the positive lead (+) from the battery (cable to starter motor).

This could cause serious

Fitting

damage to the electrical system.

If the terminals are short-

1. Connect the positive lead (+) to the battery (cable to starter motor).

circuited, sparks will be

2. Connect the negative lead (-) to the battery (cable to engine casing).

generated.

Dispose of used batteries

through an authorized waste

disposal contractor.

18. Every 400 hours:

CHECKING THE COOLANT LEVEL

MONITOR

(optional equipment)

Note: The level monitor should be checked when the engine is cold.

1. Undo the clamps on the level monitor’s lead to the wiring harness on the

engine and unplug the connector.

2. Place a receptacle under the coolant pump and unscrew the monitor.

Immediately fit a plug with an M18x1.5 thread in the hole for the moni-

tor. Avoid getting the coolant on your skin.

3. Plug in the monitor’s connector and set the control switch to ”ON”.

4. Check that the indicator lamp remains on and that the buzzer sounds.

5. Submerse the monitor in liquid in a metal receptacle (steel). It is impor-

tant to ensure that the body of the monitor is in contact with the metal.

6. The indicator lamp should go out after about 2 seconds.

7. Remove the monitor from the liquid. In about 7 seconds the indicator

lamp should come on and the buzzer start to sound.

8. Unplug the monitor’s connector and screw the monitor back in place.

9. Clamp the monitor’s lead as before and plug in the connector.

10. Fill the system with coolant as described in the specifications on

page 32.

44

2001-05:1

MISCELLANEOUS

19. Every 200 hours:

CHECK/TENSION

V-BELTS

If correctly tensioned, a pressure of 35-50 N on a drive belt

(depending on the free length of the belt) should deflect it

about 10 mm.

Change worn or damaged belts.

1. Detach the securing screws.

2. Set the correct tension using the adjusting screw.

Do not overtighten the belts.

Measurement using a Krikit belt tension gauge

(Part. No. 587 495)

1. Zero the gauge by pressing the measuring arm.

2. Place the gauge on the V-belt at an equal distance from two pulleys.

3. Press until the gauge clicks.

4. Read the gauge.

- The recommended tension of genuine Scania belts

when tested is 300 N.

When changing belts, slightly higher (10-15%) tension should be used.

2001-05:1

45

20. Daily:

LOOK FOR LEAKS,

REMEDY AS NECESSARY

- Start the engine.

- Look for leakage of oil, coolant, fuel, air and exhaust.

- Tighten or change leaking connections. Check the overflow holes (1)

Ensure that any leakage does

which show whether the O-rings between the cylinder liner and crank-

case are leaking, see drawing.

not pollute the environment.

a) If coolant is leaking out, the two upper O-rings are leaking.

b) If oil is leaking out, the lower O-ring is leaking.

- Check that the drain hole (2) on the coolant pump is not blocked, see

drawing. If there is leakage, change the pump seal.

- Check that the drain for the “V” behind the injection pump is open all

In case of major leakage,

the way through the block and drain pipe so that no fluid can collect in

contact the nearest Scania

the “V”. See drawing.

workshop.

A small amount of leakage from the overflow holes when running-in the

engine is normal. (Seals and O-rings are fitted lubricated with soap or

oil).

This leakage normally stops after a time.

If there is a large amount of leakage - contact your nearest Scania

workshop.

46

2001-05:1

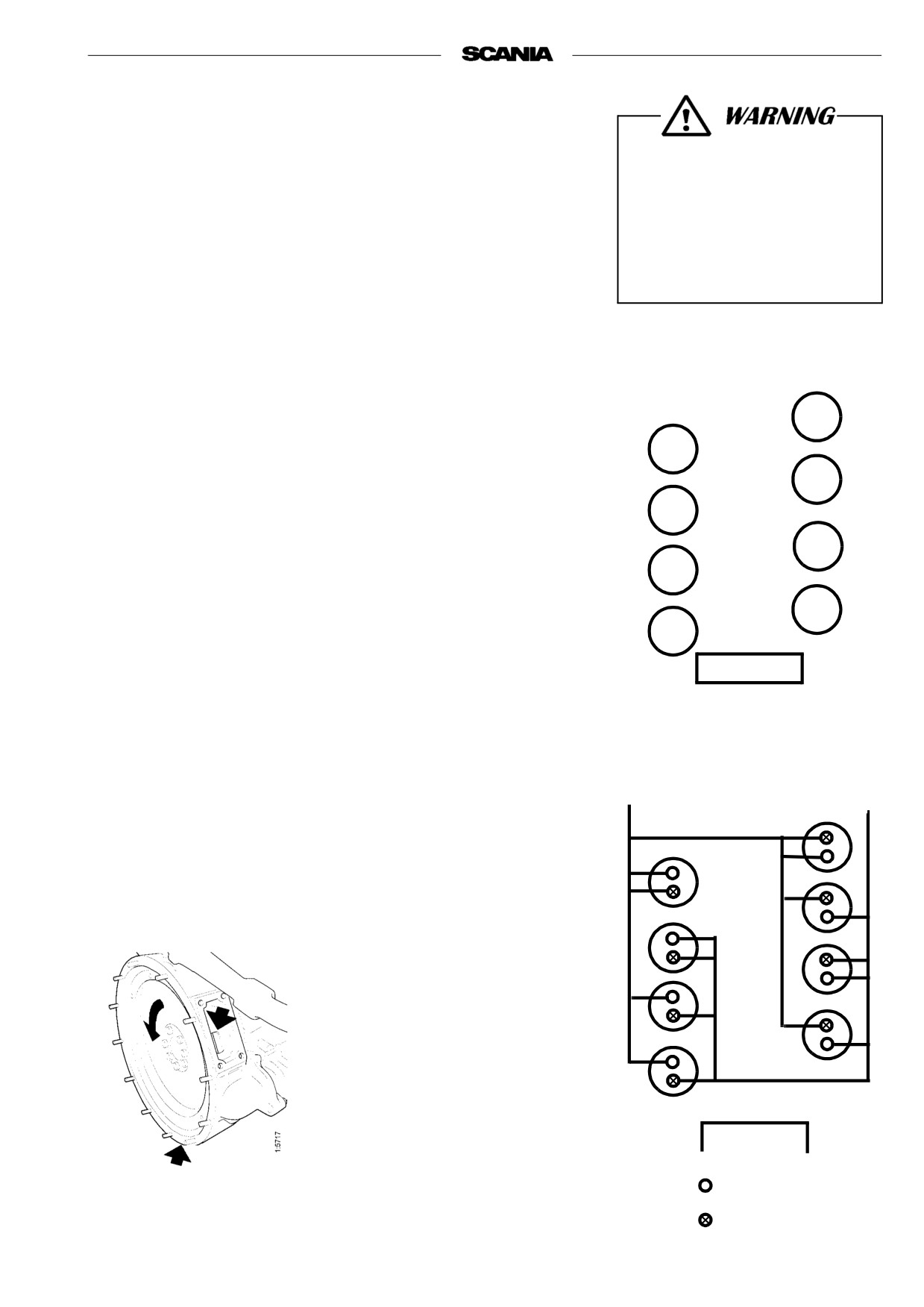

21. Every 1,200 hours:

CHECKING/ADJUSTING

Immobilise the starting device

VALVE CLEARANCE

when working on the engine.

Checking/adjusting valve clearance should be done after the

If the engine starts out of

first 400 hours of operation.

control, there is a

SERIOUS RISK

Valves should be adjusted when the engine is cold, at least 30 minutes after

OF INJURY.

running.

Rocker cover gaskets should be changed as necessary. Tightening torque:

25 Nm.

Alternative 1

- Turn the crankshaft in its direction of rotation until the piston in cylinder

No. 1 is 30°after TDC on the combustion stroke. There is a mark, ⊥, at

this position.

1

- Adjust the following valves:

5

Right side Cyl 1

Intake and exhaust

2

2

Ex

4

Ex

6

Left side Cyl 5

In and ex

7

In

3

8

In

7

- Turn the crankshaft one revolution in its direction of rotation to the

⊥ mark. The piston in cylinder No. 1 will then be 30°after TDC on the

4

induction stroke.

8

- Adjust the following valves:

FLYWHEEL

Right side Cyl 2

In

Cylinder numbering

3

In and ex

4

In

Left side Cyl 6

In and ex

No. 1 cylinder piston 30°after

7

Ex

TDC in

8

Ex

combustion

induction

stroke

stroke

Important.

On silumin housings, reading is possible

only from underneath.

On ductile cast iron housings, reading is

possible from underneath or from the

side (60°), depending on accessibility.

FLYWHEEL

Intake valve

Covers for reading

on flywheel casing

Exhaust valve

2001-05:1

47