Scania DI12. Marine engine. Operator’s manual - part 2

DEC2 CONTROL SYSTEM

This engine has an injection pump with an electromagnetic actuator which

adjusts the control rack to give the correct amount of fuel.

The system which controls the pump is called DEC2 (Digital Engine Control,

generation 2).

The control unit (DEC2) continuously receives signals from sensors for

engine speed, charge air temperature and pressure, coolant temperature, oil

pressure, throttle position and control rack travel in the injection pump. Using

this input data and a control program, the correct amount of fuel for the

current operating conditions can be calculated.

The system's sensors may be used only for DEC2, not for other instruments

or other monitoring purposes.

The control unit contains monitoring functions to protect the engine in the

event of a fault which would otherwise damage it. Faults and the more

important monitoring functions are indicated on the control unit in the form

of light emitting diodes. See illustration on page 18 for a description.

In case of a fault, the Power - or Shutdown indicator on the DEC2 control

unit as well as the main indicator lamp on the main supply box and the

instrument panel will illuminate.

If a fault has been indicated on the main indicator lamp the operator can

determine the cause of the fault with the help of the LEDs on the control unit

and the troubleshooting schedule on page 21, and carry out the required

investigation and remedy.

Depending on the nature of the fault, the control system will take different

actions to protect the engine such as reducing the power output, keeping the

engine running at a constant low speed or, in case of a function impairing

fault, shutting down the engine (Shutdown).

To enable readout of LED fault codes there is a lamp test/fault code switch

located in the main supply box near the control unit.

A PC based program is also available to help service personnel to detect and

rectify faults and to adjust certain parameters in the operating program.

Diagnostics and changes to programs must only be performed by

authorized personnel.

The locations of the sensors and monitors that send signals to the control unit

are shown in the illustrations on pages 17.

There is a description of the functions of the LEDs during normal operation

on page 18.

On page 19 there is a description of the functions of the LEDs in case of a

fault and actions in case of Power- and Shutdown indication.

Troubleshooting and fault code reading are described on pages 20 and 21.

16

Location of sensors for DEC2 on DI12

1. Connection of lead to charge air

temperature sensor

2. Charge air temperature sensor

3. Oil pressure monitor

4. Connector panel

5. Coolant temperature sensor

6. Engine speed sensorse

17

LED functions during normal operation

Note: The lamp test/fault code switch should not be

POWER-

depressed. All LEDs come on briefly when

P The LED remains out during normal operation

the control unit is powered up.

as long as no fault is detected by the control

unit. See next page for the procedure to be

CONTROL STATUS

adopted in the event of a fault.

< The LED flashes continuously when the control

unit is supplied with current, regardless of

POWER+

whether the engine is running or not.

< If the control unit is programmed to allow the

engine to be operated according to more than

SHUTDOWN

one power/torque curve (map), the following

P The LED is out.

applies.

The LED comes on when the engine is run at

STARTING

more than 100% power output (MAP 2). It goes

< The LED lights up as soon as the engine turns

out when the engine returns to the 100% power

over on cranking and follows the programmed

output curve (MAP 1) or when the power output

starting sequence until it has been completed

required is less than 100%.

and then goes out.

RUNNING

< The LED comes on when the engine has started

and the "Starting" LED goes out. It remains on

until the engine is stopped.

TORQUE LIMIT

< The LED comes on when the control unit

detects that the engine has received the

maximum permissible quantity of injected fuel

according to its power curve. This means 100%

power output at the current rpm. If the load

increases, engine rpm will decrease.

BOOST LIMIT

< The LED comes on when the control unit smoke

limiter restricts the maximum fuel quantity.

Operation of the smoke limiter is dependent on

the charge air pressure.

18

Action in case of a fault

LED indications in case of a fault

Note The main indicator lamp in the main supply

box and at the instrument panel has

indicated a fault. The lamp test/fault code

switch should not be depressed.

CONTROL STATUS

< The LED will continue to flash even in case of a

fault as long as voltage is supplied to the control

unit.

POWER -

< If the LED comes on, the control unit has

detected a defect that could cause damage to the

engine if operation continues.

The control unit automatically reduces engine

power output to a predefined level if the

corresponding function has been selected.

Action: Reduce engine speed to idle if possible

and conduct troubleshooting according to

instructions on page 20 and the chart on page 21

SHUTDOWN

< The LED comes on and the engine is switched

off automatically in case of a severe fault that

could cause damage to the engine if operation

continues.

Action: Conduct troubleshooting according to

instructions on page 20 and the chart on page 21

If the engine has not stopped, reduce engine

speed to idle and conduct troubleshooting.

19

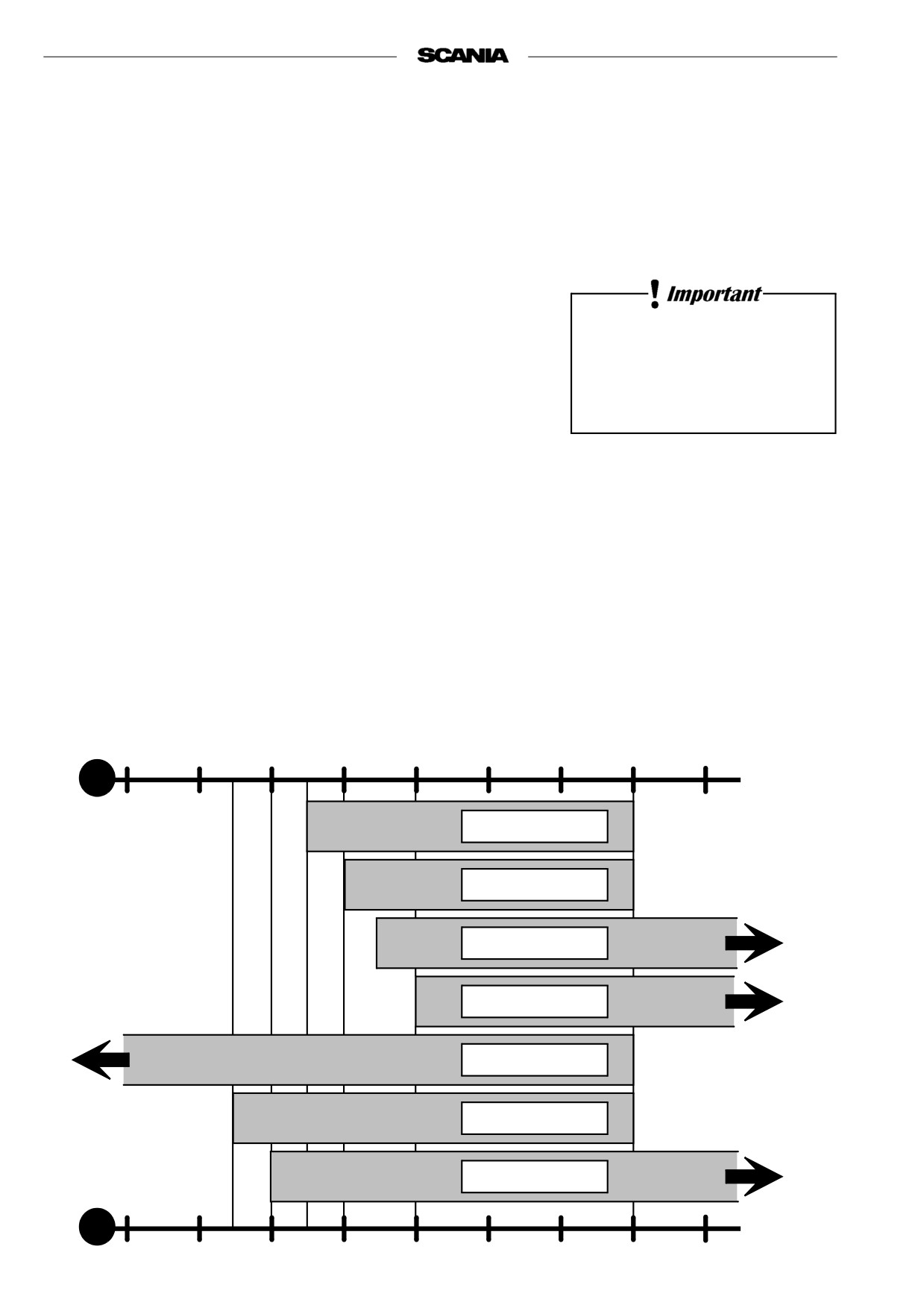

Changing functions using the DIP

Readout of fault codes

switches in the control unit

Note If the engine has stopped or lost power but

There are 8 DIP switches in the control unit under the

the main indicator lamp is out and neither

round black rubber cover.

POWER- nor SHUTDOWN are on, the

fault is outside the control unit detection

These switches shall be in the ON position to obtain

range. Probable causes: fuel shortage,

normal functions according to the operating program.

temporary overload, mechanical fault.

However, for single-speed engines, the normal

position of DIP switches 6, 7, and 8 may also be OFF

-

Activate the lamp test/fault code switch. In

Scania electrical equipment the main indicator

Shutdown at threshold values for low oil pressure and

lamp is located in this switch on the main supply

high coolant temperature can be selected by setting

box.

DIP switch 4 to OFF

-

All LEDs will then come on for 2 seconds to

With DIP switch 4 in position ON, Power- indication

indicate that they are intact and in working order.

is obtained for these threshold values. Engine output

This also applies to the main indicator lamp in the

reduction (LOP) can be selected to prevent damage to

main supply box and the instrument panel. Make

the engine. Changes to the program must only be

a note of any LED that is defective.

performed by authorized personnel.

-

All LEDs will then be out for approximately 4

Note

Do not operate the engine with a Power-

seconds.

indication except for in emergencies.

-

Following this, a fault code will be indicated on

one of the LEDs for 2 seconds. Note which LED

it is.

-

The control unit then resumes the operating mode

automatically.

-

After having made a note of the fault code, reset

the lamp test/fault code switch and reset the

control unit by turning off its power supply

momentarily.

-

The most probable cause of the fault can then be

found in the trouble shooting schedule on the next

page.

-

When the fault or faults have been rectified the

engine can be restarted.

-

If the control system continues to indicate a fault

by way of the main indicator lamp, further faults

may have been recorded. The fault code readout

must then be repeated as per above since the

system can only display one fault code at a time.

-

The fault(s) will be stored in a special memory in

the control unit along with information about the

operating time when it(they) occurred. Stored

faults can be accessed and erased by authorised

service personnel.

The DIP switches are showed in ON position

20

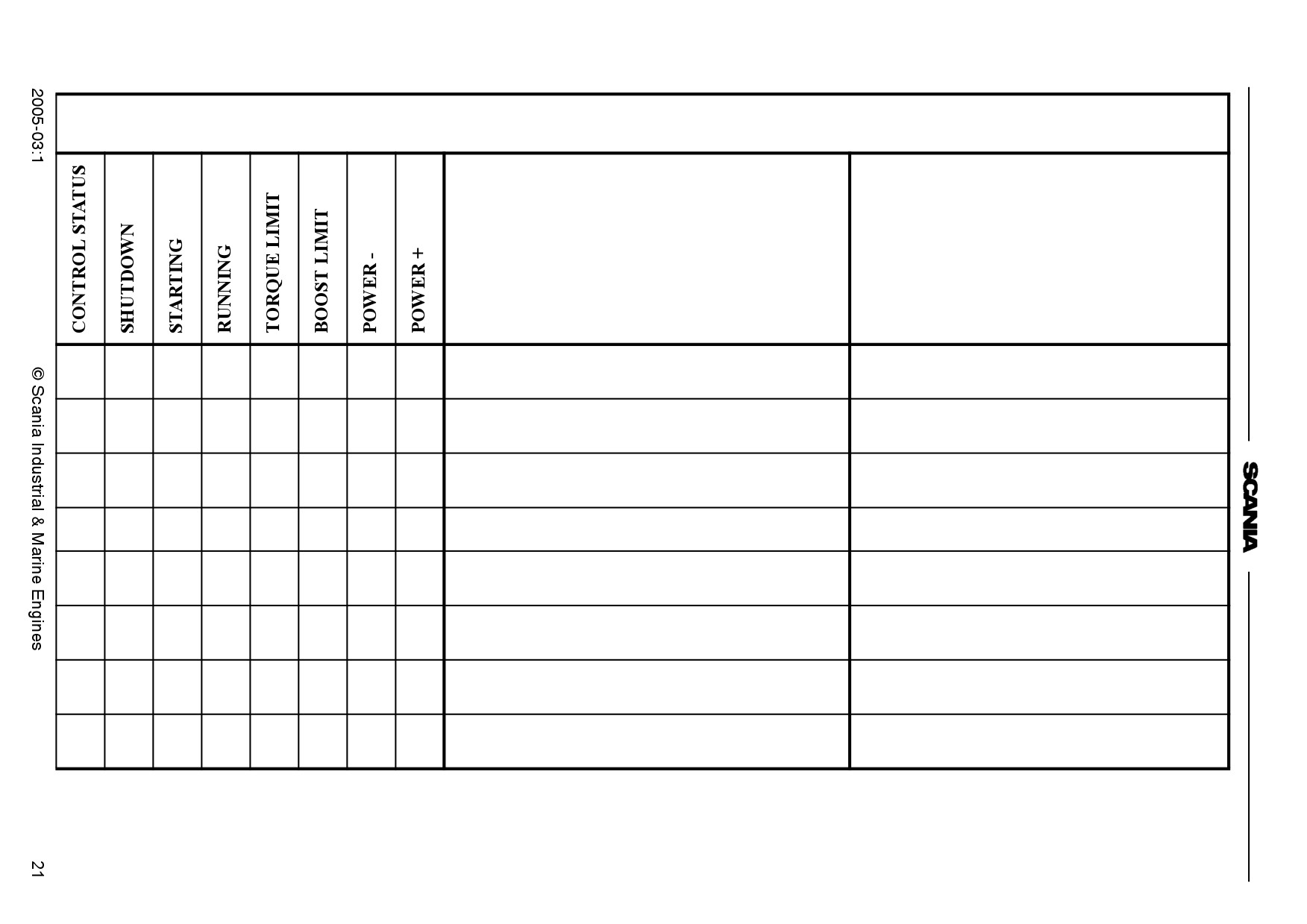

READOUT OF FAULT CODES

LED INDICATION WHEN THE LAMP TEST/FAULT CODE SWITCH IS ACTIVATED

Probable cause

Action

Send in the control unit for repair as soon as

<

DEC2 has detected an internal fault in the control unit.

possible.

The engine temperature has reached the threshold level

Check the cooling system. Check the temperature

<

or the temperature sensor is inoperative.

sensor and cable routing.

The engine has reached the overrevving limit or the

Check the wiring and connector.

<

engine speed sensor is inoperative.

Renew the engine speed sensor.

<

Control rack position sensor inoperative.

Check connectors and cables to governor.

The intake air temperature has reached the threshold

Check the intake system. Check the temperature

<

level or the charge air temperature sensor is inoperative.

sensor and cable routing.

DEC2 detects no charge air pressure.

Check the charge air pressure hose. Send in the

<

The charge air pressure sensor is inoperative.

control unit for repair if the connection is damaged.

Engine speed potentiometer or the idling safety switch

Check the cable routing, connectors and cables.

<

is inoperative.

The oil pressure has dropped to the threshold level or

Check oil level, connector and cable.

<

the oil pressure monitor is inoperative.

Renew the oil pressure monitor.

<=LED on

STARTING AND RUNNING

AT FIRST START

Coolant composition:

When the engine is started for the first time, follow the maintenance points

listed under "First start" in the maintenance schedule, see page 29.

If there is a danger of freezing:

Since the points are important for satisfactory operation of the engine right

minimum 30% glycol by volume

from the outset, they are also listed below.

maximum 60 % glycol by volume

1. Checking the oil level (refer to page 31).

8. Checking the coolant (refer to page 36).

If there is no danger of freezing:

The coolant should contain corrosion inhibitor to protect the cooling

7-12% by volume

system from corrosion.

Scania Anti-corrosive

If there is a danger of freezing:

(no glycol)

- Only anti-freeze glycol should be used in the coolant as protection

against corrosion. We recommend only nitrite-free anti-freeze glycols

with the following supplier designations:

BASF G48 or BASF D542

- The concentration of glycol should be 30 - 60% by volume depending

Ethylene glycol and corrosion

on the ambient temperature. A content of 30 % by volume provides

inhibitor, if swallowed can be

protection down to -16 °C. Refer to page 36.

fatal.

- Never top up with only water or only glycol. Fluid losses must always

Avoid contact with the skin.

be replaced with pre-mixed coolant having the same glycol

concentration as that in the engine. If the glycol content drops, both

anti-freeze protection and protection against corrosion are impaired.

Note A glycol concentration below 30% by volume will not provide suf-

ficient protection against corrosion. Glycol concentrations higher

The recommended glycol must

than 60 % do not improve anti-freeze protection and have a nega-

not be mixed with glycol having

tive effect on engine cooling capacity.

nitrite-based anti-corrosive.

If there is no danger of freezing:

- Only Scania Anti-corrosive should be used in the coolant as protection

against corrosion. The correct corrosion inhibitor content is 7-12% by

volume and must never be less than 7% by volume. The inhibitor in

Scania Anti-corrosive is free of nitrite.

The use of too much Scania

- First filling: Fill the cooling system with water + 10% by volume of

Anti-corrosive as mixed with

Scania Anti-corrosive. Use drinkable water with a pH value of 6 - 9.

glycol may cause deposits.

- Never top up with only water or only anti-corrosive! Fluid losses

must always be replaced with premixed coolant:

water + 10 % by volume of Scania Anti-corrosive.

Coolant filter (not standard equipment)

Only coolant filter without inhibitor may be used. The use of coolant filters

If a coolant filter has been fitted

increases the life of the coolant and reduces the risk of deposition corrosion.

it must not contain inhibitor.

22

14. Checking the fuel level (refer to page 45).

17. Checking the electrolyte level in batteries (refer to page 47).

18. Checking the state of charge in batteries refer to page 47).

20. Checking the coolant level monitor (if fitted) (refer to page 48).

Immobilise the starting device

21. Checking the temperature monitor (refer to page 49).

when working on the engine.

If the engine starts out of

22. Checking the oil pressure monitor (refer to page 50).

control, there is a

23. Checking the tension of drive belts (refer to page 51).

SERIOUS RISK

OF INJURY.

CHECKS BEFORE RUNNING

Before running, "Daily maintenance" as described in the maintenance sche-

dule should be carried out, see page 29.

STARTING THE ENGINE

If the fuel tank has been run dry or if the engine has not been used for a long

time, bleed the fuel system (see page 45).

For environmental reasons, your new Scania engine has been designed to use

a smaller amount of fuel when starting. Using unnecessarily large amounts of

Only start the engine in a

fuel when starting the engine always results in the discharge of unburnt fuel.

properly ventilated area.

- Open the fuel cock, if fitted.

When operating the engine in

- Declutch the engine (not engines with fixed clutch, e.g. generator sets).

an enclosed area, an effective

extraction device for exhaust

- Engines with battery master switch: Switch on the power by means of

gases and crankcase gases

the battery master switch.

must be used.

- DEC2: If the main indicator lamp comes on or flashes when the power is

turned on, this indicates the presence of a fault in the control system or

engine which must be found and rectified before the engine is started.

Refer to page19.

- Start the engine by means of the starter button or starter key.

Starting at low temperatures

Never use starting spray or

Local environmental requirements must be complied with. Starting aids,

similar as a starting aid.

engine heaters and/or flame start devices should be used to avoid starting

problems and white smoke.

An explosion may occur in the

intake pipe, which could cause

To limit white smoke, the engine should be run at low speed and under mode-

rate load. Avoid running it longer than necessary at idling speed.

personal injury.

23

At temperatures below 0 °C:

Note Only use starting aids recommended by Scania.

- The starter motor may only be used for 30 seconds at a time. After that

time it must cool for 2 minutes.

If the engine has flame start:

- Operating flame start without timer relay: Press the control button,

which also acts as a pre-glow button (max. 20 seconds). The glow plug

Maximum starter engagement

continues to glow as long as this button is depressed after the engine has

time is 30 seconds. Risk of

started. Maximum time is 5 minutes.

overheating. Allow starter to

- Operating flame start with timer relay: Press the pre-glow button (a

cool for 2 minutes after a

maximum of 20 seconds). Release it when the engine starts. The timer

starting attempt before

relay keeps the glow plug glowing for 5 minutes. If a shorter glow time

cranking again.

is required, press the release button. The key must be turned to the 0

position if the start attempt fails.

Note If the engine is equipped with an INTERLOCK switch, this

switch should be depressed and held until the oil pressure has

reached a sufficiently high level.

- Generator sets should be operated under load immediately after starting

to avoid the risk of white smoke. This applies in particular to engines

that have been installed without aids for heating or applying a basic

load.

- Warm up the engine with a light load. A light load on a cold engine

gives better combustion and faster heating than warming up with no

load.

24

Running

Check instruments and warning lamps at regular intervals.

Engine speed

The Scania tachometer is divided into sectors of different colours, as follows:

0-500 rpm

red area:

prohibited engine speed,

passed when stopping and

starting.

500-700 rpm

yellow area:

low idle.

700-2200 rpm

green area:

normal operating speed.

The engine's operating

speed range is controlled by

the DEC2 control system.

2200-2600 rpm

yellow/green

unsuitable operating speed.

striped:

May occur when switching

off.

2600-3000 rpm

red area:

prohibited engine speed

Coolant temperature

Normal coolant temperature when the engine is running should be 70 - 90°C.

DEC2: If the temperature is high, 98°C or above, you can select for the

control system to reduce power output (Power -) in order to bring down the

temperature. Refer to the DEC section on page 20.

If the temperature continues to rise, the engine will be shut down

automatically (Shutdown) at 103°C. Refer to the DEC section on page 20.

Excessively high coolant temperature can damage the engine.

If run for extended periods under an extremely light load, the engine may

have difficulty in maintaining normal operating temperature. However, the

temperature will rise to a normal level again when the load on the engine is

increased.

25

Oil pressure

Max. oil pressure:

hot engine at engine speed exceeding 800 rpm

6 bar

Normal oil pressure:

hot engine at operating speed

3 - 6 bar

High lubricating oil pressure

Min. oil pressure:

(above 6 bar) is normal when

hot engine at 800 rpm

0.7 bar

starting a cold engine.

At engine speeds below 800 rpm the gauge may indicate low oil pressure

although no fault is present.

Oil pressures below 0.7 bar at engine speeds above 800 rpm will cause

engine damage. The engine must be stopped immediately.

DEC2: The engine is shut down automatically if this function has been

selected. Refer to the DEC section on page 20.

Charging indicator lamp

If the lamp comes on during operation:

- Check/adjust the alternator drive belts as described in the maintenance

step. Refer to page 51.

- If the charging indicator lamp is still on, this could be due to an alter-

nator fault or a fault in the electrical system.

STOPPING THE ENGINE

1. Run the engine without a load for a few minutes if it has been run

continuously with a heavy load.

There is danger of turbo damage

2. Stop the engine with the stop button. Keep the stop button depressed

and post boiling if the engine is

until the engine is completely stationary.

stopped without cooling.

3. DEC2: Before switching off, check that the control system's main

indicator lamp is not on or flashing.

Refer to page 19 for troubleshooting.

4. Engines with battery master switch: Switch the power off with the

The power must not be switched

battery master switch.

off before the engine has

stopped.

5. Set the control switch to "0".

26

Clutch

- See the manufacturer's instructions for handling and operating the

clutch.

WARNING If the clutch output shaft is rotating (e.g. in multiple eng-

ine installations where other engines are running), the clutch can,

under its own power, be drawn to the engaged position.

THIS MAY CAUSE PERSONAL INJURY and engine damage.

For this reason, always secure the clutch in the disengaged posi-

tion if there is a risk of the output shaft starting to rotate.

CHECKS AFTER RUNNING

- Check that the power is cut from the battery master switch and that the

control switch is in the "0" position.

Immobilise the starting device

when working on the engine.

- Fill the fuel tank. Make sure that the filler cap and the area round the

filler opening are clean to avoid contamination of the fuel.

If the engine starts out of

control, there is a

- If there is a risk of freezing, the cooling system must be drained if it

SERIOUS RISK

does not contain a sufficient amount of glycol, refer to page 36.

OF INJURY.

- Close inlet valve for the sea water system (if fitted).

- If there is danger of freezing, the sea water system must be emptied.

- At temperatures below 0 °C: Prepare for the next start by switching on

the engine heater (if fitted).

Top up engine coolant when the

engine has been stopped after

being started for the first time.

27

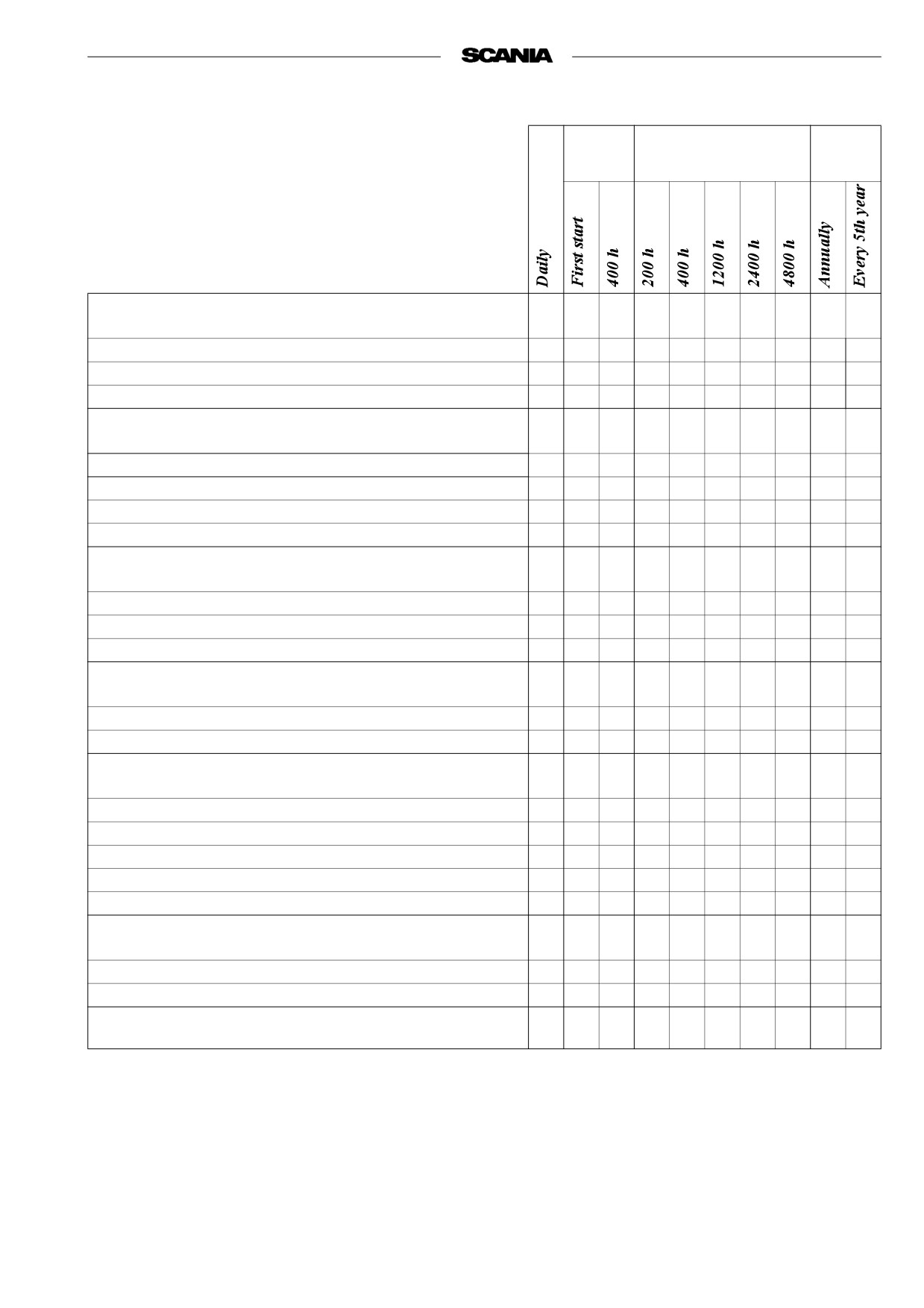

MAINTENANCE

The maintenance programme covers 26 points, divided into the following

main groups:

Lubricating oil system

page 30

Cooling system

page 34

Immobilise the starting device

Air cleaner

page 42

Fuel system

page 45

when working on the engine.

Electrical system, monitors, batteries etc. . . page 47

If the engine starts out of

Miscellaneous

page 51

control, there is a

SERIOUS RISK

OF INJURY

The maintenance points are divided into intervals as follows:

Daily maintenance

Maintenance before first start

Maintenance after the first 400 hours of operation

Periodic maintenance every 200 hours of operation (carried out after 200,

400, 600, 800, etc. hours)

Periodic maintenance every 400 hours of operation (carried out after 400,

800, 1200, 1600, etc. hours)

Periodic maintenance every 1200 hours of operation (carried out after 1200,

2400, 3600, etc. hours)

Periodic maintenance every 2400 hours of operation (carried out after 2400,

4800 etc. hours)

Periodic maintenance every 4800 hours of operation (carried out after 4800,

9600, etc. hours)

Annual Maintenance

Maintenance every 5th year

ENGINES WITH FEW HOURS OF

OPERATION

Run the engine until it reaches operating temperature and then carry out the

For engines with few operating

maintenance points below:

hours that are not subject to

1. Checking the oil level.

periodic maintenance according

to the maintenance schedule on

5. Checking the coolant level.

page 29, maintenance should be

10. Checking the vacuum sensor.

carried out in accordance with

14. Checking the fuel level.

the schedule:

17. Checking the electrolyte level in batteries.

"Every year"

"Every 5 years"

18. Checking the state of charge in batteries.

19. Cleaning the batteries.

24. Checking for leakage, rectify as necessary

28

MAINTENANCE SCHEDULE

First

Interval

At least

time at

LUBRICATING OIL SYSTEM, page 30

z

z

1. Checking the oil level

2. Oil change

z

1

z

3. Cleaning the oil cleaner

z

1

z

4. Renewing the oil filter

z

1

z

COOLING SYSTEM, page 34

z

5. Checking the coolant level

6. Checking the corrosion bars 4)

z

5

z

7. Checking the marine water pump impeller 4)

z

5

z

8. Checking the coolant

z

6

z6

9. Cleaning the cooling system

z

1

z

AIR CLEANER, page 42

z

10. Checking the vacuum sensor

11. Cleaning the coarse cleaner

z

1

z

12. Cleaning or renewing filter element

z

3

z

13. Renewing the safety cartridge

z

FUEL SYSTEM, page 45

z

z

14. Checking the fuel level

15. Renewing the main filter

z

1

z

16. Checking the injectors

z

ELECTRICAL SYSTEM, page 47

z

2

z

z

17. Checking the electrolyte level in batteries

18. Checking the state of charge in batteries

z

2

z

z

19. Cleaning the batteries

z

2

z

20. Checking the level monitor

z

21. Checking the temperature monitor

z

22. Checking the oil pressure monitor

z

MISCELLANEOUS, page 51

z

23. Checking the drive belt

24. Checking for leakage, rectify as necessary

z

25. Checking/adjusting valve clearance

z

26. Renewing (or cleaning) the valve for closed crankcase

z

ventilation

1. More often if required.

2. For engines with few operating hours, see page 28.

3. Earlier if low pressure indicator shows red.

4. Only applies to M engines with sea water pump.

5. Reference value. Varies depending on the composition of the sea water.

6. If inhibitor has not been topped up for five years, the coolant should be changed.

29

LUBRICATING OIL SYSTEM

OIL GRADE

The engine oil must at least meet the requirements for one of the following

oil classifications:

-ACEA E3, E4 or E5

- The Total Base Number (TBN) should be minimum 12-13

(ASTM 2896).

- Check with your oil supplier that the oil meets these requirements.

Additives must not be used.

- The specified oil change intervals apply provided that the fuel sulphur

content does not exceed 0.3% by weight. If the sulphur content exceeds

The oil should be suitable for all

0.3 % but is maximum 1.0%, the oil change intervals must be halved

temperature variations until the

(200 h).

next oil change.

- Viscosities as illustrated below.

- For operation at extremely low ambient temperature: Consult your

nearest Scania representative on how to avoid starting difficulties.

Oil analysis

Some oil companies can offer analysis of the engine oil. Such analysis

measures the oil TBN (Total Base Number), TAN (Total Acid Number), fuel

dilution, water content, viscosity and the quantity of friction particles and

soot in the oil.

The result of a series of analyses is used as the basis for establishing a

suitable oil change interval.

If the conditions are changed, a new oil analysis programme must be carried

out to establish the new change interval.

-40

-30

-20

-10

0

10

20

30

40

°C

SAE 20W-30

SAE 30

SAE 40

SAE 50

SAE 5W-30

SAE 10W-30

SAE 15W-40

30

1. Daily:

CHECKING THE OIL LEVEL

Note Before checking oil level: Allow the engine to remain stopped for

at least 1 minute.

- The correct level is between the marks on the dipstick. Top up when the

level is at the lower mark.

- Correct type, see "Oil grade" on page 30.

Checking oil level during operation

On some engines the oil level can be checked during operation.

- Remove the oil filler cap to release the pressure in the crankcase.

- Check the level on the dipstick, correct oil level: 10 mm below the mini-

mum and the maximum mark.

10 mm

10 mm

2. Every 400 hours:

OIL CHANGE

Note Under extremely severe operating conditions, especially in dusty

environment or if the deposits in the centrifugal cleaner are

thicker than 20 mm: change oil more frequently.

- Pump out the oil with the oil bilge pump when the engine is warm.

- Fill up with new oil.

- Check the level on the dipstick.

3

Max 33 dm

Min 28 dm3

Always use a suitable container

to avoid spillage when

changing oil.

The oil may be hot.

Dispose of used oil through an

Wear protective gloves and

authorized waste disposal

goggles

contractor.

Max 28 dm3

Min 20 dm3

Maximum angles of inclination during operation

1 dm3 = 1 liter

Maximum permissible angles during operation vary, depending on the type

of oil sump, see illustration..

Note Specified angles may only occur intermittently.

25°

25°

25°

35°

25°

3

5°

35°

31