Scania DC16 EMS with S6/PDE. Industrial engine. Operator’s manual - part 3

3. Every 400 hours:

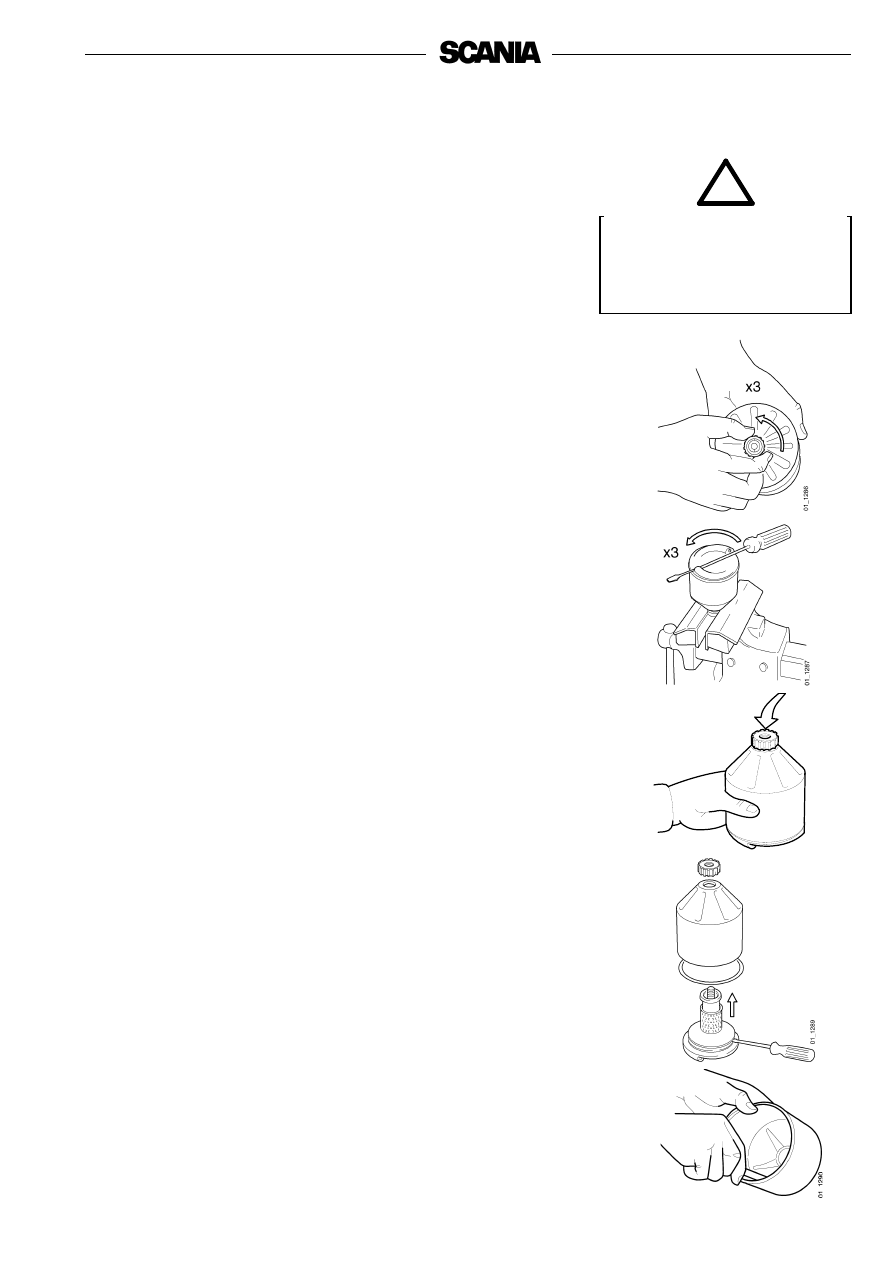

Cleaning the oil filter unit

(in connection with oil change)

01

12

88

Open the cover carefully. The

oil may be hot.

WARNING

!

- Clean the cover. Unscrew the nut and remove the cover.

- Lift out the rotor and loosen the nut on the rotor cover three turns.

- If the nut is jammed:

Clamp the nut, but never the rotor, in a vice and turn the rotor three

turns by hand or with a screwdriver.

- Tap the nut lightly with your hand or a plastic hammer, to detach the

rotor cover from the bottom plate.

- Unscrew the nut and remove the rotor cover.

- Remove the strainer located on the rotor. If the strainer is stuck, you can

prise its bottom edge carefully until it comes loose from the bottom

plate.

- Scrape off the deposits from the inside of the rotor cover. If there are no

deposits, this indicates that the cleaner is not working properly.

- If the deposits are thicker than 20 mm: clean more often.