содержание .. 14 15 16 17 ..

Scania Central gear RP832-RBP832. Manual - part 16

08:04-02

©

61

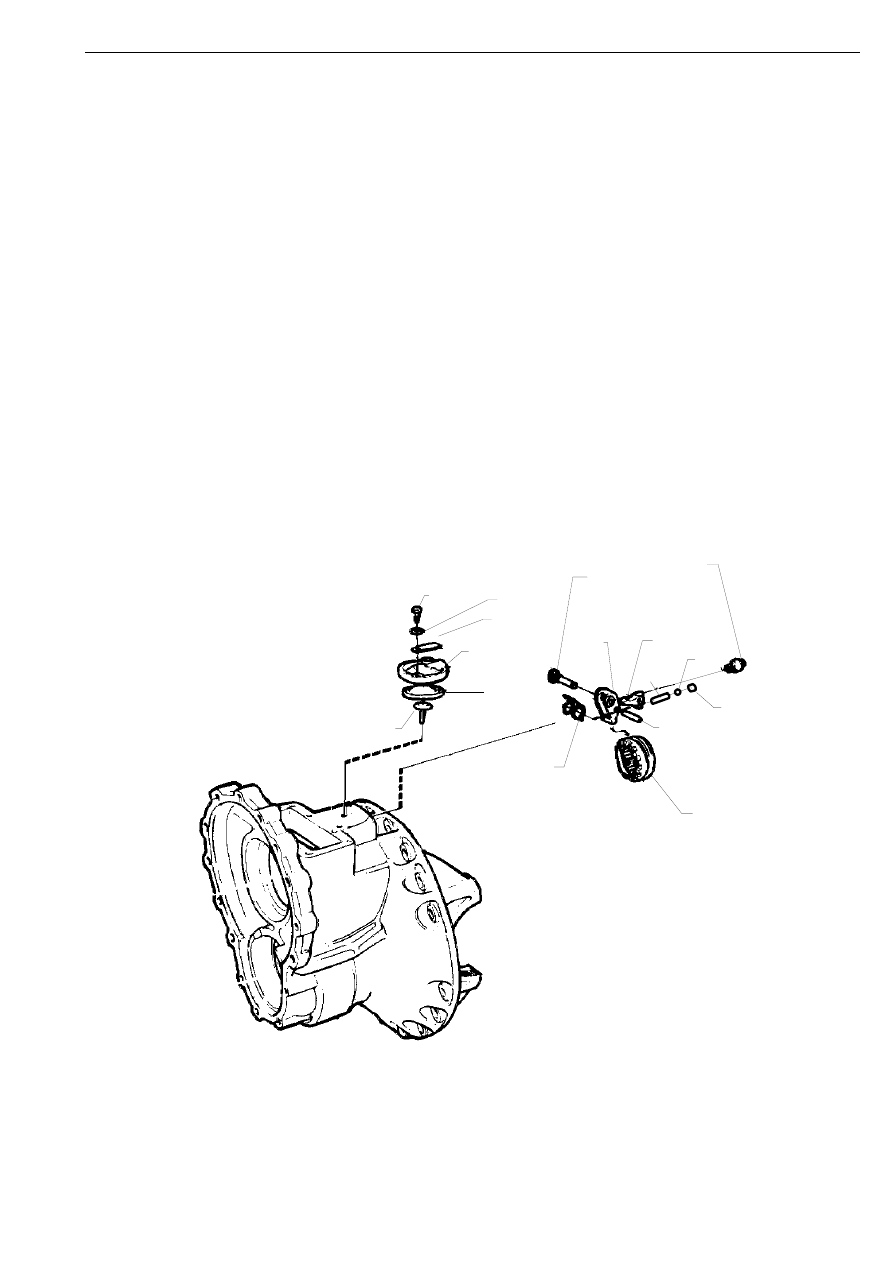

Dismantling the bogie differential lock

1

Remove the cover 51, diaphragm 50 and

piston 49 for the differential lock. Take out

the differential lock.

2

Remove the switch 48.

3

Unscrew shaft 44 and take out the levers

40 and 42 with spring 41.

52

53

58

49

50

51

44

39

41

43

47

40

42

45

46

48

111 450

Bogie differential lock

Bogie differential lock