Renault Espace (2016 year). Instruction - part 16

4.11

Replacing the battery

As this operation is complex, we advise

you to contact an approved Dealer.

BATTERY

(2/2)

The battery is a speci-

fic type, please ensure it

is replaced with the same

type. Consult an approved

dealer.

A

2

3

4

5

6

7

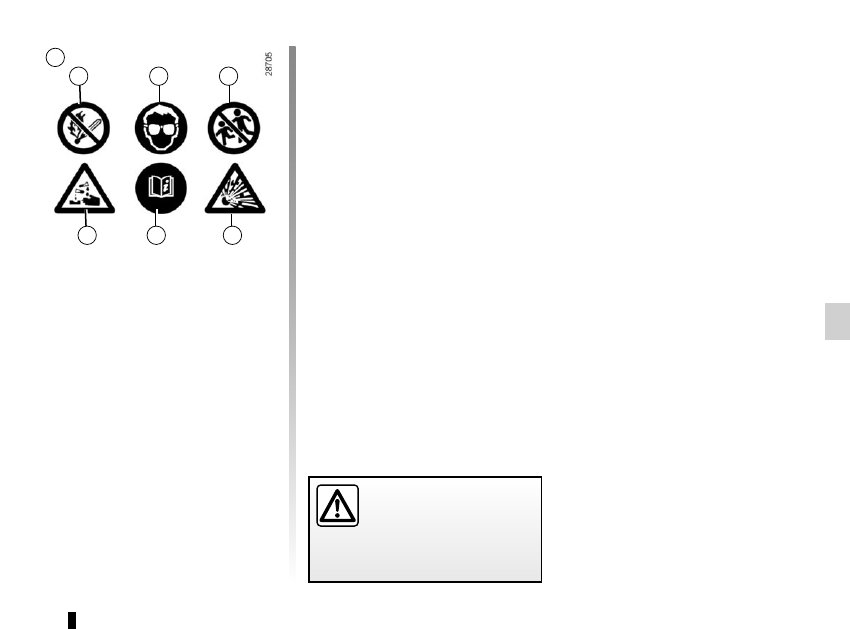

Label A

Observe the indications on the battery:

– 2 Naked flames and smoking are for-

bidden;

– 3 eye protection required;

– 4 keep away from children;

– 5 explosive materials;

– 6 refer to the handbook;

– 7 corrosive materials.