Nissan Note E12. Manual - part 236

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

EC-283

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

DTC Logic

INFOID:0000000009022646

DTC DETECTION LOGIC

NOTE:

• If DTC P2101 is displayed with DTC P2100, first perform the trouble diagnosis for DTC P2100. Refer

.

• If DTC P2101 is displayed with DTC P2119, first perform the trouble diagnosis for DTC P2119. Refer

.

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V when

engine is running.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 2 seconds.

2. Start engine and let it idle for 5 seconds.

3. Check DTC.

Is DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009022647

1.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E15. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

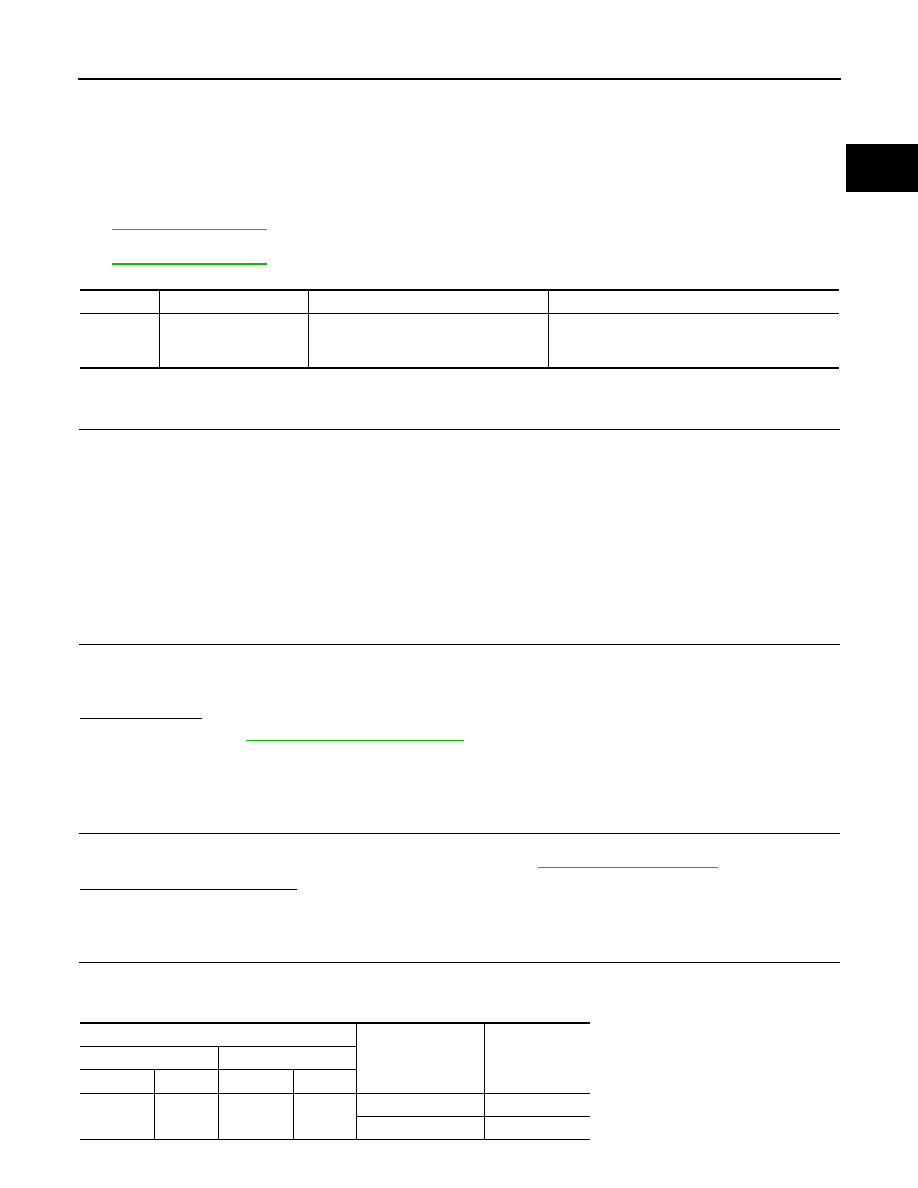

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P2101

Electric throttle control

performance

Electric throttle control function does not

operate properly.

• Harness or connectors

(Throttle control motor circuit is open or shorted)

• Electric throttle control actuator

ECM

Condition

Voltage

+

−

Connector

Terminal

Connector

Terminal

F10

2

E16

108

Ignition switch OFF

Approx. 0 V

Ignition switch ON

Battery voltage