Nissan Pathfinder (2011 year). Manual - part 228

DLN-362

< UNIT DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: R180A]

FRONT FINAL DRIVE

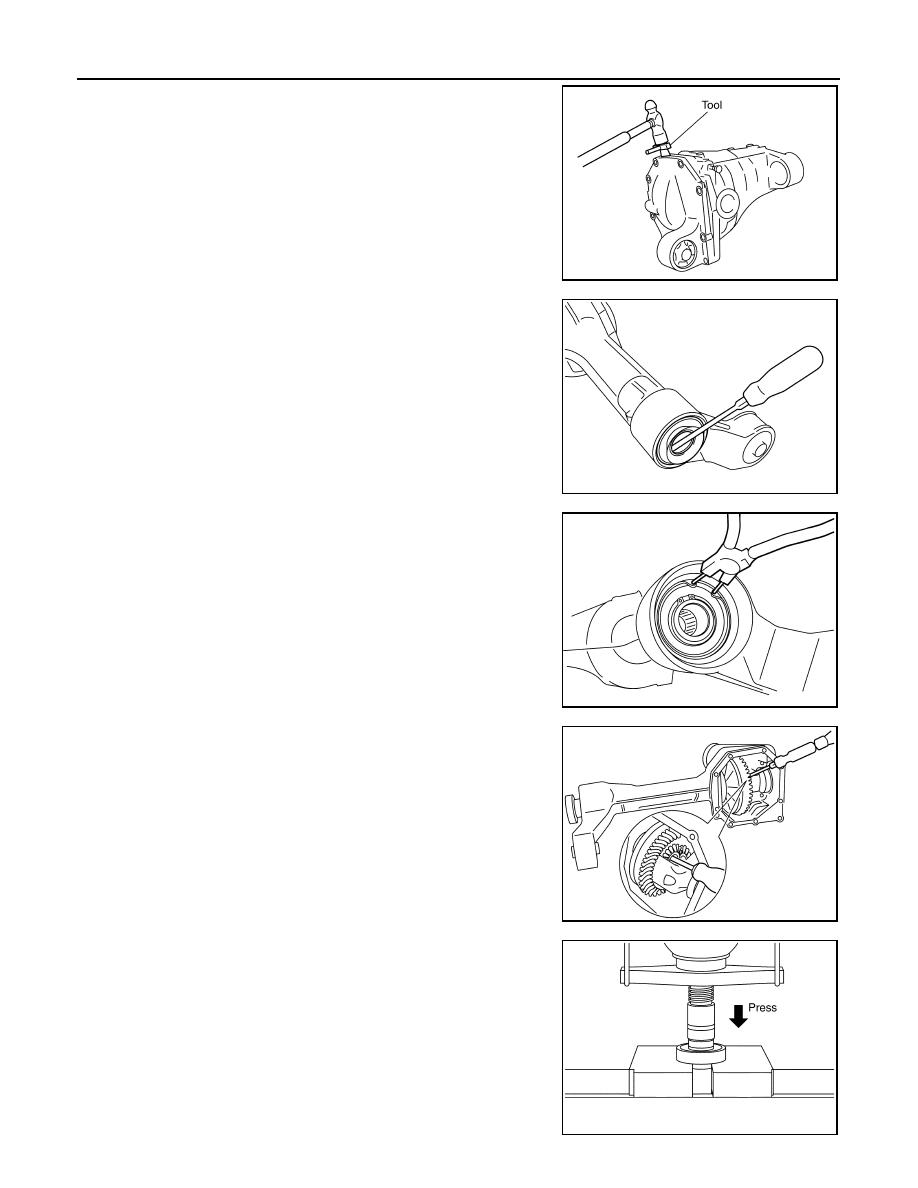

2. Remove the carrier cover bolts and separate the carrier cover

from the gear carrier using Tool.

CAUTION:

• Do not damage the mating surface.

• Do not insert flat-bladed screwdriver, this will damage the

mating surface.

3. Remove side oil seal, using suitable tool.

CAUTION:

Do not damage gear carrier.

4. Remove snap ring (hole side) using suitable tool.

5. Remove differential side shaft assembly out of gear carrier using

suitable tool.

NOTE:

Tap on differential side shaft assembly from side gear side.

6. Remove snap ring (differential side shaft side).

7. Press differential side shaft out of differential side shaft bearing.

CAUTION:

Do not drop differential side shaft.

Tool number

: KV10111100 (J-37228)

PDIA0699E

PDIA0713E

PDIA0714E

PDIA0715E

PDIA0718E

2011 Pathfinder