Nissan Pathfinder (2008 year). Manual - part 595

TM-102

< COMPONENT DIAGNOSIS >

MAIN POWER SUPPLY AND GROUND CIRCUIT

3.

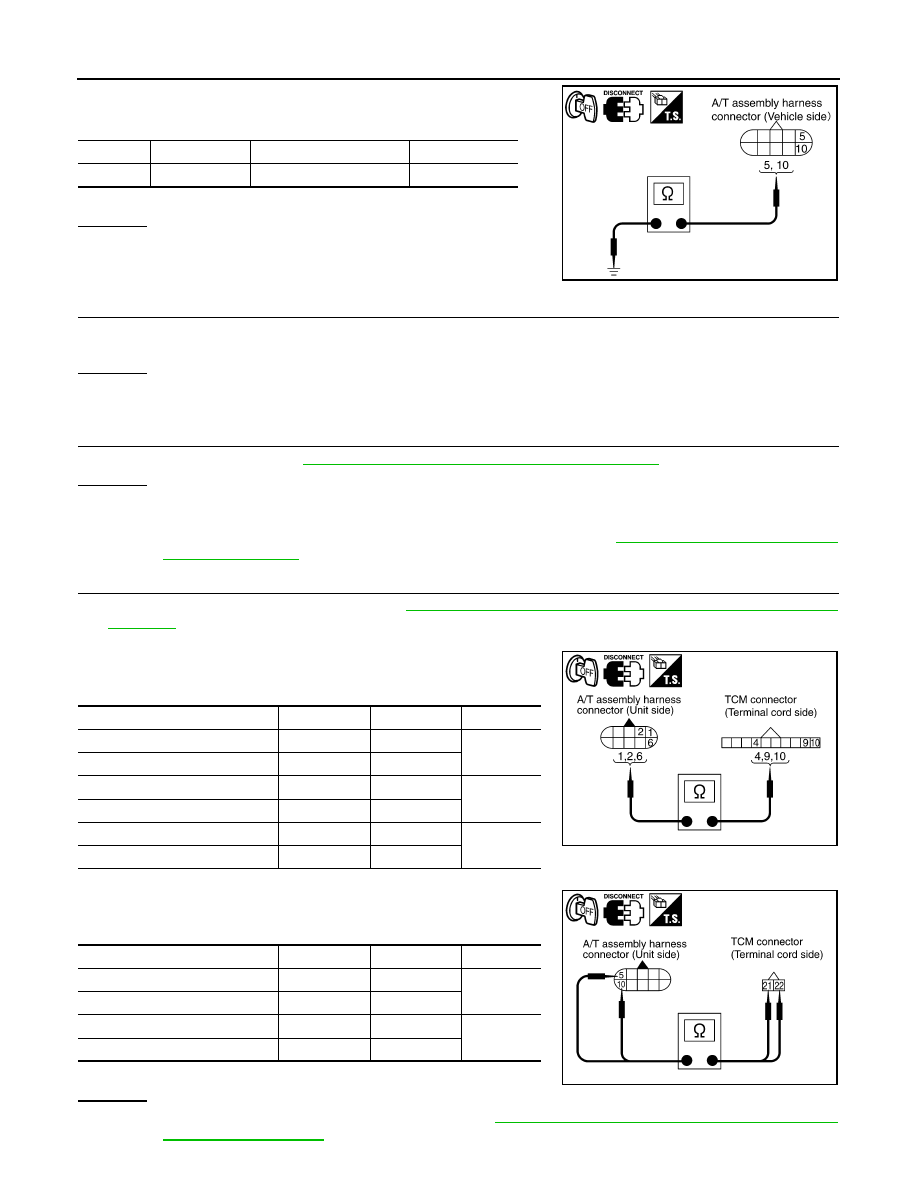

Check continuity between A/T assembly harness connector ter-

minals and ground.

If OK, check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 5.

NG

>> Repair open circuit or short to ground or short to power

in harness or connectors.

5.

DETECT MALFUNCTIONING ITEM

Check the following.

• The A/T assembly harness connector terminals for damage or loose connection with harness connector.

OK or NG

OK

>> GO TO 6.

NG

>> Repair or replace damaged parts.

6.

PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to

TM-35, "CONSULT-III Function (TRANSMISSION)"

OK or NG

OK

>> INSPECTION END

NG-1

>> Self-diagnosis does not activate: GO TO 7.

NG-2

>> DTC is displayed: Check the malfunctioning system. Refer to

7.

CHECK TERMINAL CORD ASSEMBLY

1.

Remove control valve with TCM. Refer to

TM-199, "Control Valve with TCM and A/T Fluid Temperature

.

2.

Disconnect A/T assembly harness connector and TCM connector.

3.

Check continuity between A/T assembly harness connector ter-

minals and TCM connector terminals.

4.

Check continuity between A/T assembly harness connector ter-

minals and TCM connector terminals.

5.

If OK, check harness for short to ground and short to power.

OK or NG

OK

>> Replace the control valve with TCM. Refer to

TM-199, "Control Valve with TCM and A/T Fluid

.

Item

Connector

Terminal

Continuity

TCM

F9

5, 10 - Ground

Yes

SCIA2106E

Item

Connector

Terminal

Voltage

A/T assembly harness connector

F9

1

Yes

TCM connector

F502

9

A/T assembly harness connector

F9

2

Yes

TCM connector

F502

10

A/T assembly harness connector

F9

6

Yes

TCM connector

F502

4

SCIA5464E

Item

Connector

Terminal

Voltage

A/T assembly harness connector

F9

5

Yes

TCM connector

F504

21

A/T assembly harness connector

F9

10

Yes

TCM connector

F504

22

SCIA5465E