Nissan Pathfinder (2008 year). Manual - part 468

IP-16

< DISASSEMBLY AND ASSEMBLY >

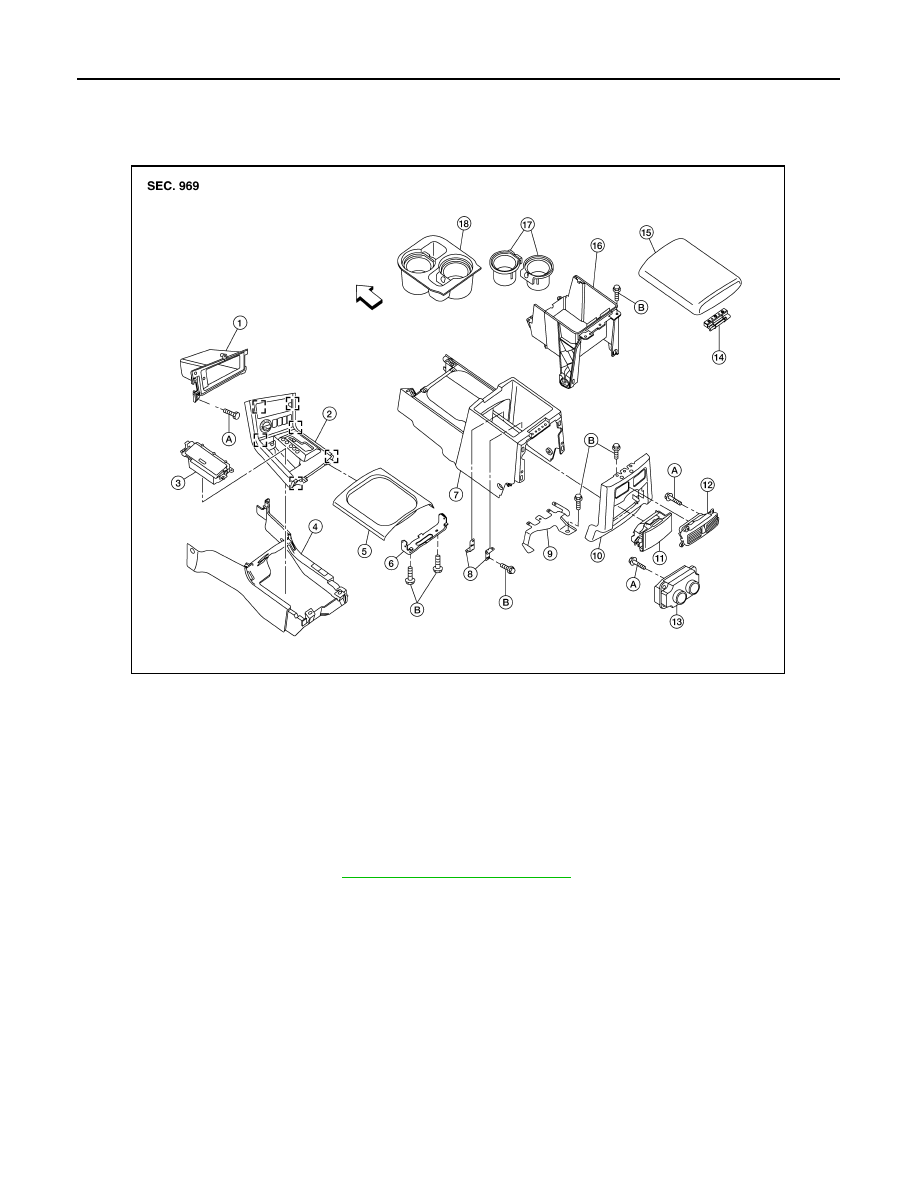

CENTER CONSOLE ASSEMBLY

Assembly

Assembly is in the reverse order of disassembly.

Center Console

Disassembly

1.

Remove center console. Refer to

IP-10, "Removal and Installation"

2.

Remove center console lid.

3.

Remove latch from center console lid.

4.

Remove hinge from center console lid.

5.

Remove rear finisher assembly.

6.

Remove rear cup holder assembly.

7.

Remove DVD player, if equipped.

8.

Disconnect center console harness connectors.

9.

Remove cup holder insert and cup holder assembly.

10. Remove center console bin.

11. Remove center console bracket.

12. Remove wire harness bracket.

Assembly

AWJIA0058ZZ

1.

Console bin

2.

A/T finisher

3.

Ash tray

4.

Center console front base

5.

Cup holder finisher

6.

Bracket

7.

Center console rear base

8.

Bracket DVD

9.

Wire harness bracket

10.

Rear finisher assembly

11.

Rear cup holder assembly

12.

Ventilator console grille (if equipped)

13.

Rear HVAC control (if equipped)

14.

Hinge

15.

Center console lid

16.

Center console bin

17.

Cup holder insert

18.

Cup holder assembly

A.

Screw

B.

Bolt