Nissan Pathfinder (2008 year). Manual - part 430

COMPRESSOR

HA-43

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

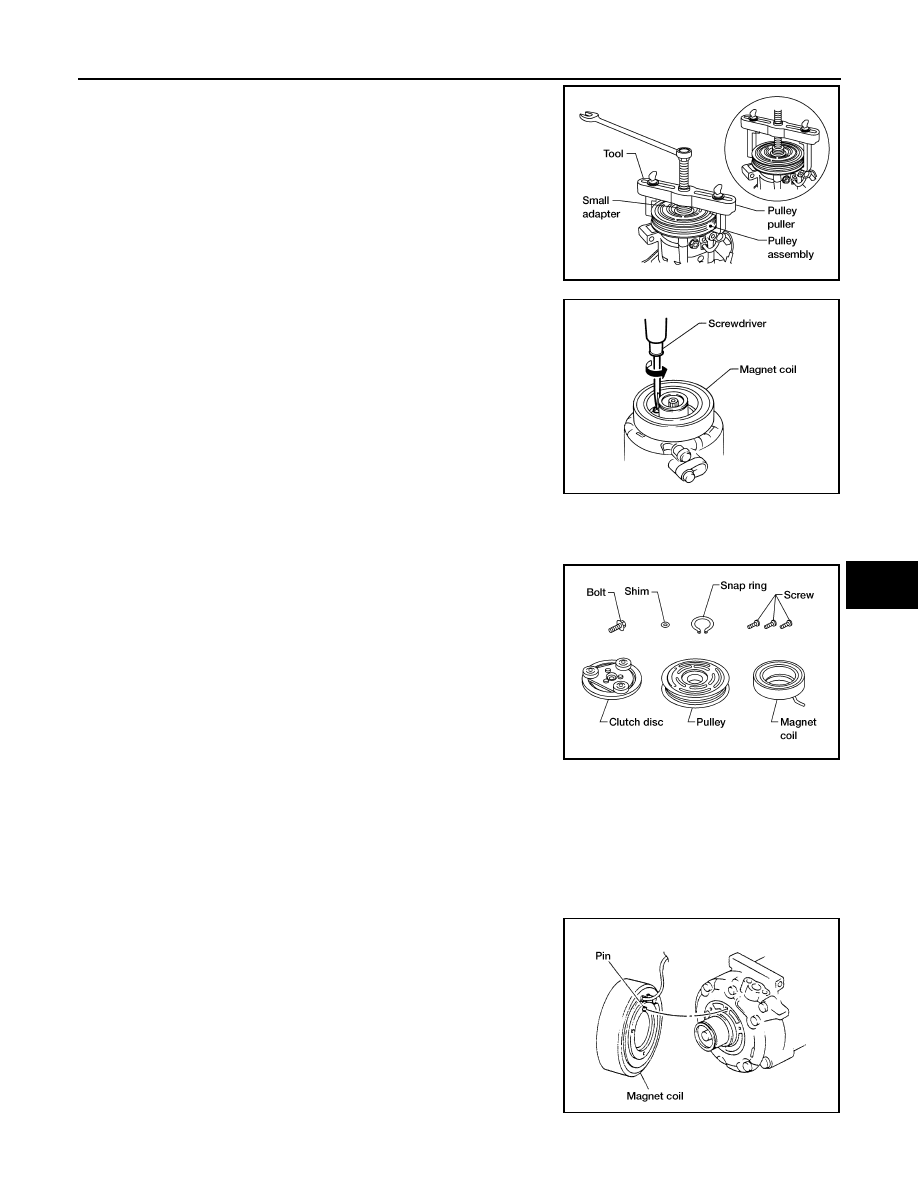

5.

Remove the pulley using Tool with a small adapter. Position the

small adapter on the end of the drive shaft and the center of the

puller on the small adapter.

CAUTION:

To prevent deformation of the pulley groove, the puller

claws should be hooked under the pulley groove and not

into the pulley groove.

6.

Remove the magnet coil harness clip using a screwdriver,

remove the three magnet coil fixing screws and remove the

magnet coil.

INSPECTION

Clutch Disc

If the contact surface shows signs of damage due to excessive heat,

replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If contact surface of pulley shows signs of excessive grooving,

replace clutch disc and pulley. The contact surfaces of the pulley assembly should be cleaned with a suitable

solvent before reinstallation.

Coil

Check magnet coil for loose connections or any cracked insulation.

INSTALLATION

1.

Install the magnet coil.

CAUTION:

Be sure to align the magnet coil pin with the hole in the

compressor front head.

2.

Install the magnet coil harness clip using a screwdriver.

Tool number

: KV99233130 (J-29884)

WJIA1017E

WHA212

WHA183

WHA213