Nissan Pathfinder (2008 year). Manual - part 428

OIL

HA-27

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

OIL

Maintenance of Oil Quantity in Compressor

INFOID:0000000001675595

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage has occurred. It is important to maintain the spec-

ified amount.

If oil quantity is not maintained properly, the following malfunctions may result:

• Lack of oil: May lead to a seized compressor

• Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

Oil name: NISSAN A/C System Oil Type S or equivalent

CHECKING AND ADJUSTING

CAUTION:

If excessive oil leakage is noted, do not perform the oil return operation.

Start the engine and set the following conditions:

Test Conditions

• Engine speed: idling to 1,200 rpm

• A/C switch: ON

• Blower fan speed: HIGH

• Temperature control: optional [set so intake air temperature is 25

°

to 30

°

C (77

°

to 86

°

F)]

• Intake position: RECIRCULATION mode

• Perform oil return operation for about ten minutes

Adjust the oil quantity according to the following table.

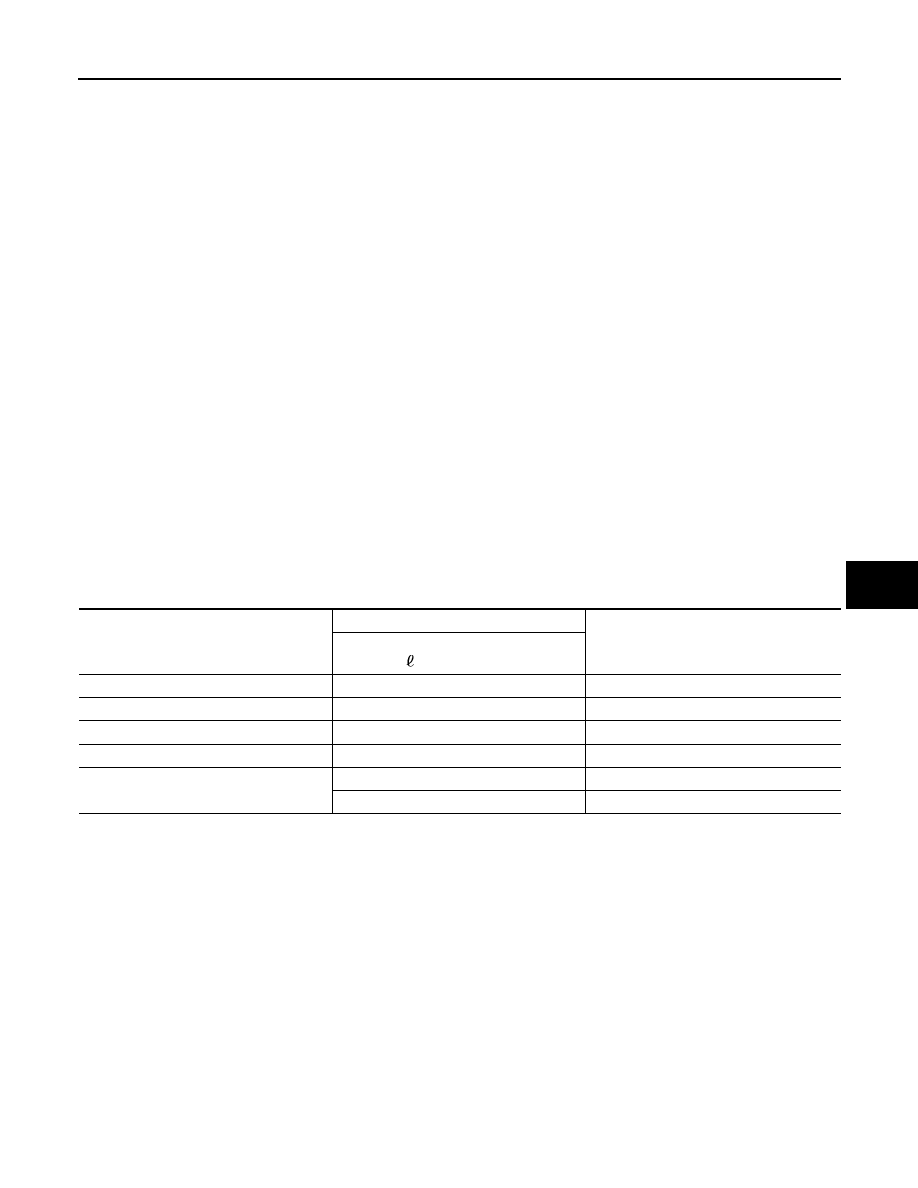

Oil Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of oil to the system.

Amount of Oil to be Added

*1:

If refrigerant leak is small, no addition of oil is needed.

Oil Adjustment Procedure for Compressor Replacement

Part replaced

Oil to be added to system

Remarks

Amount of oil

m

(US fl oz, Imp fl oz)

Front evaporator

75 (2.5, 2.6)

—

Rear evaporator

75 (2.5, 2.6)

—

Condenser

75 (2.5, 2.6)

—

Liquid tank

5 (0.2, 0.2)

Add if compressor is not replaced.

In case of refrigerant leak

30 (1.0, 1.1)

Large leak

—

Small leak *1