Nissan Pathfinder (2008 year). Manual - part 374

AIR CLEANER FILTER

EM-155

< ON-VEHICLE MAINTENANCE >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

AIR CLEANER FILTER

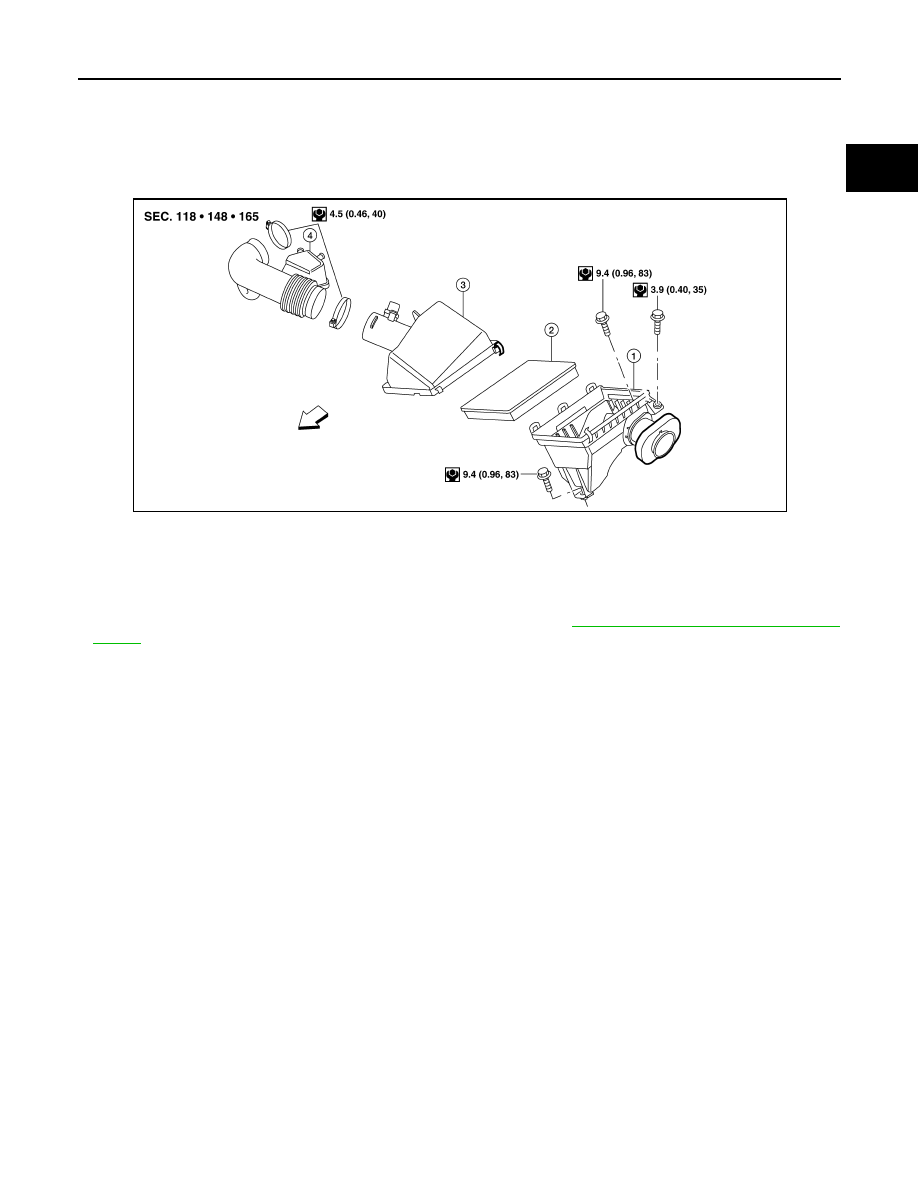

Removal and Installation

INFOID:0000000001468877

REMOVAL

NOTE:

• The viscous paper type filter does not need cleaning between replacement intervals.

• Replace the air filter as necessary for periodic maintenance. Refer to

MA-6, "Introduction of Periodic Mainte-

.

1.

Unhook clips, and lift air cleaner case (upper).

2.

Remove the air cleaner filter.

INSTALLATION

1.

Installation is in the reverse order of removal.

1.

Air cleaner case (lower)

2.

Air cleaner filter

3.

Air cleaner case (upper)

4.

Air duct and resonator assembly

⇐

Front

ALBIA0413GB