Nissan Pathfinder (2008 year). Manual - part 372

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-139

< SERVICE DATA AND SPECIFICATIONS (SDS)

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

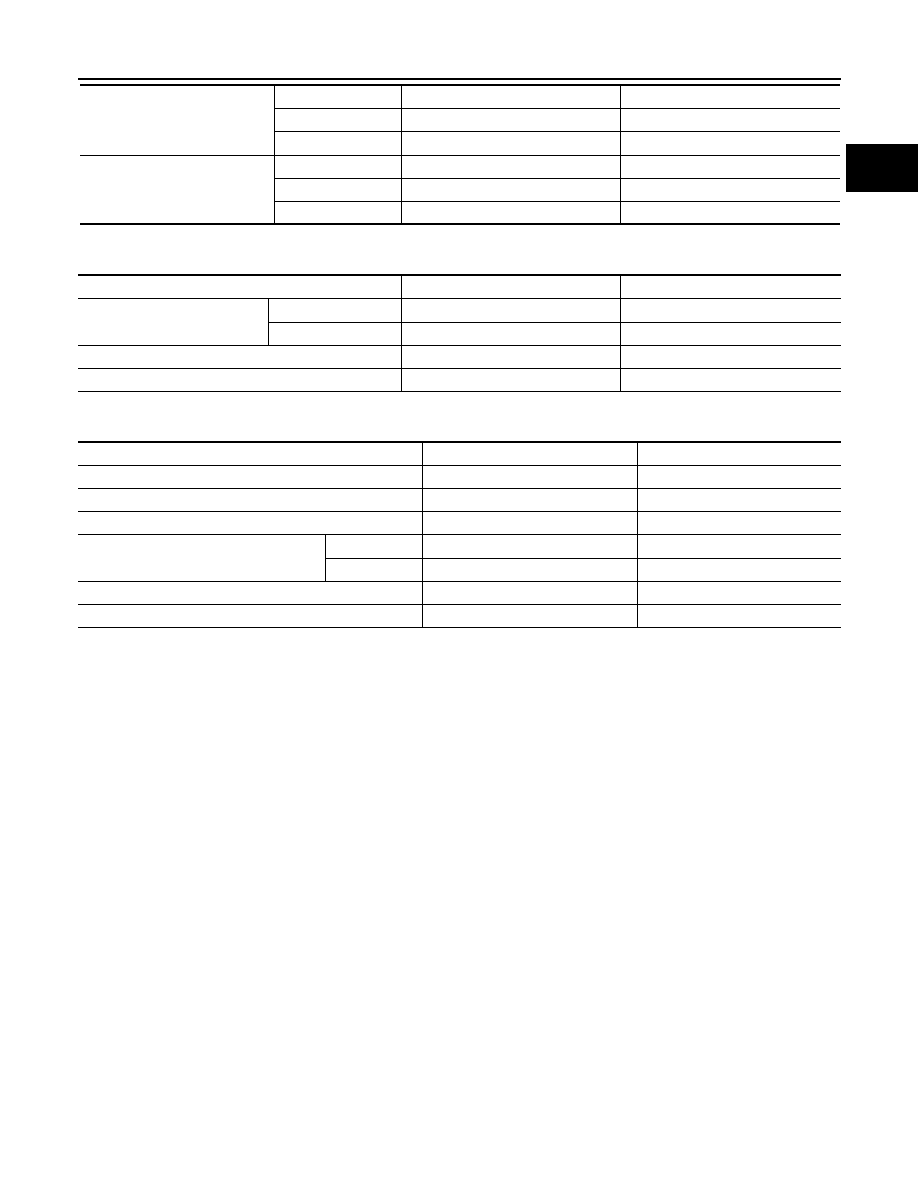

Piston Pin

Unit: mm (in)

CONNECTING ROD

Unit: mm (in)

*: After installing in connecting rod

CRANKSHAFT

Side clearance

Top

0.045 - 0.080 (0.0018 - 0.0031)

0.11 (0.0043)

2nd

0.030 - 0.070 (0.0012 - 0.0028)

0.10 (0.0039)

Oil ring

0.065 - 0.135 (0.0026 - 0.0053)

—

End gap

Top

0.23 - 0.33 (0.0091 - 0.0130)

0.56 (0.0220)

2nd

0.33 - 0.48 (0.0130 - 0.0189)

0.68 (0.0268)

Oil (rail ring)

0.20 - 0.50 (0.0079 - 0.0197)

0.85 (0.0335)

Items

Standard

Limit

Piston pin outer diameter

Grade No. 0

21.989 - 21.995 (0.8657 - 0.8659)

—

Grade No. 1

21.995 - 22.001 (0.8659 - 0.8662)

—

Piston to piston pin oil clearance

0.002 - 0.006 (0.0001 - 0.0002)

—

Connecting rod bushing oil clearance

0.005 - 0.017 (0.0002 - 0.0007)

0.030 (0.0012)

Items

Standard

Limit

Center distance

165.82 - 165.92 (6.5283 - 6.5323)

—

Bend [per 100 (3.94)]

—

0.15 (0.0059)

Torsion [per 100 (3.94)]

—

0.30 (0.0118)

Connecting rod bushing inner diameter*

Grade No. 0

22.000 - 22.006 (0.8661 - 0.8664)

—

Grade No. 1

22.006 - 22.012 (0.8664 - 0.8666)

—

Connecting rod big end diameter (Without bearing)

57.000 - 57.013 (2.2441 - 2.2446)

—

Side clearance

0.20 - 0.35 (0.0079 - 0.0138)

: 40 mm (0.0157)