Nissan Pathfinder (2008 year). Manual - part 370

ENGINE UNIT

EM-123

< DISASSEMBLY AND ASSEMBLY >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

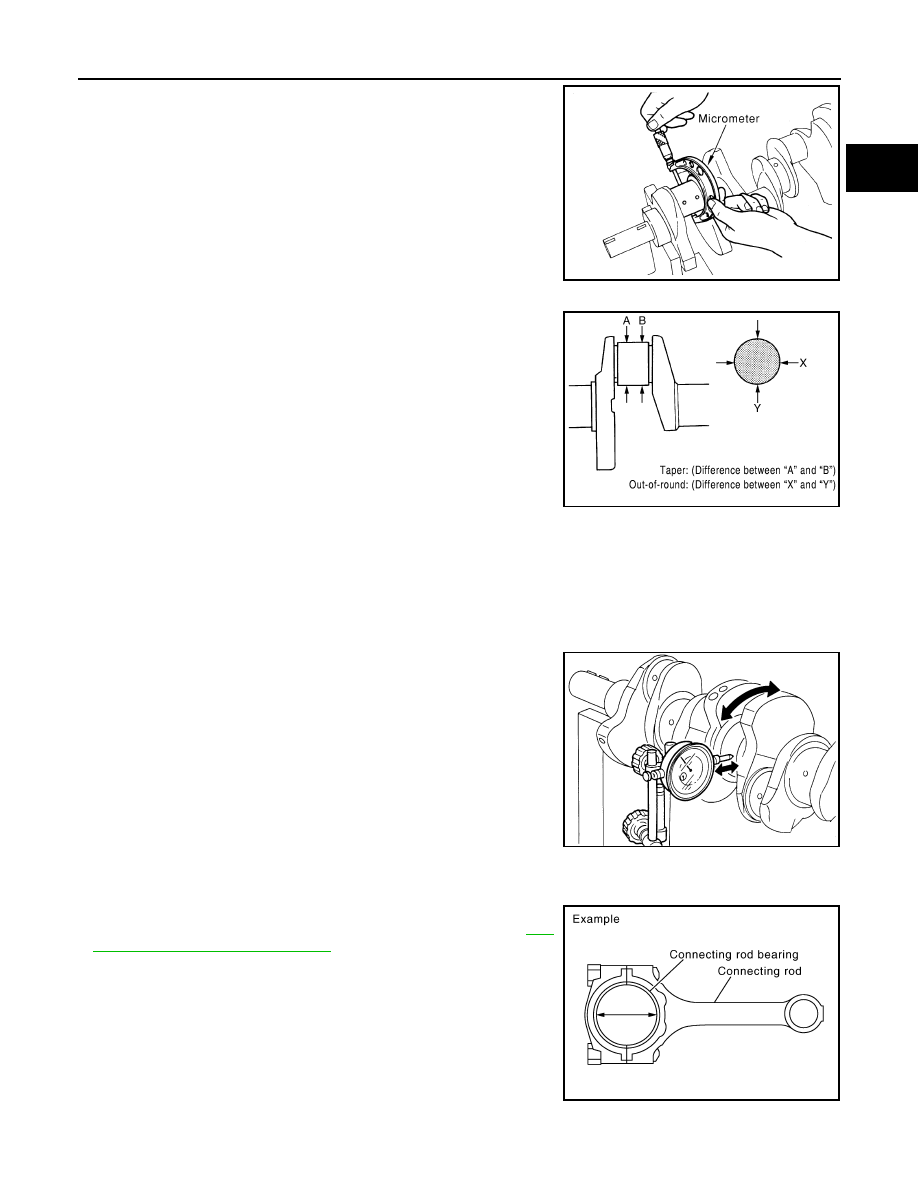

• Measure the outer diameter of crankshaft pin journal with

micrometer.

• If out of the standard, measure the connecting rod bearing oil

clearance. Then use undersize bearing. Follow the "CONNECT-

ING ROD BEARING OIL CLEARANCE" procedure.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

• Measure the dimensions at four different points as shown on each

main journal and pin journal with micrometer.

• Out-of-round is indicated by the difference in the dimensions

between “X” and “Y” at “A” and “B”.

• Taper is indicated by the difference in the dimensions between “A”

and “B” at “X” and “Y”.

• If the measured value exceeds the limit, correct or replace crankshaft.

• If corrected, measure the bearing oil clearance of the corrected main journal and/or pin journal. Then select

the main bearing and/or connecting rod bearing. Follow the "MAIN BEARING OIL CLEARANCE" and/or

"CONNECTING ROD BEARING OIL CLEARANCE" procedures.

CRANKSHAFT RUNOUT

• Place V-block on precise flat table, and support the journals on the

both end of crankshaft.

• Place dial indicator straight up on the No. 3 journal.

• While rotating crankshaft, read the movement of the pointer on dial

indicator. (Total indicator reading)

• If it exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

• Install connecting rod bearings to connecting rod and cap, and

tighten connecting rod bolts to the specified torque. Refer to

106, "Disassembly and Assembly"

• Measure the inner diameter of connecting rod bearing with inside

micrometer.

(Bearing oil clearance) = (Connecting rod bearing inner diameter) –

(Crankshaft pin journal diameter)

Standard

: 53.956 - 53.974 mm (2.1242 - 2.1250 in) dia.

PBIC0127E

Limit:

Out-of-round (Difference between “X” and “Y”)

: 0.002 mm (0.0001 in)

Taper (Difference between “A” and “B”)

: 0.002 mm (0.0001 in)

SBIA0535E

Standard

: Less than 0.05 mm (0.002 in)

Limit

: 0.10 mm (0.0039 in)

SEM346D

Standard

: 0.034 - 0.059 mm (0.0013 - 0.0023 in) (actu-

al clearance)

Limit

: 0.070 mm (0.0028 in)

PBIC1642E