Nissan Pathfinder (2008 year). Manual - part 366

OIL SEAL

EM-91

< ON-VEHICLE REPAIR >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

5.

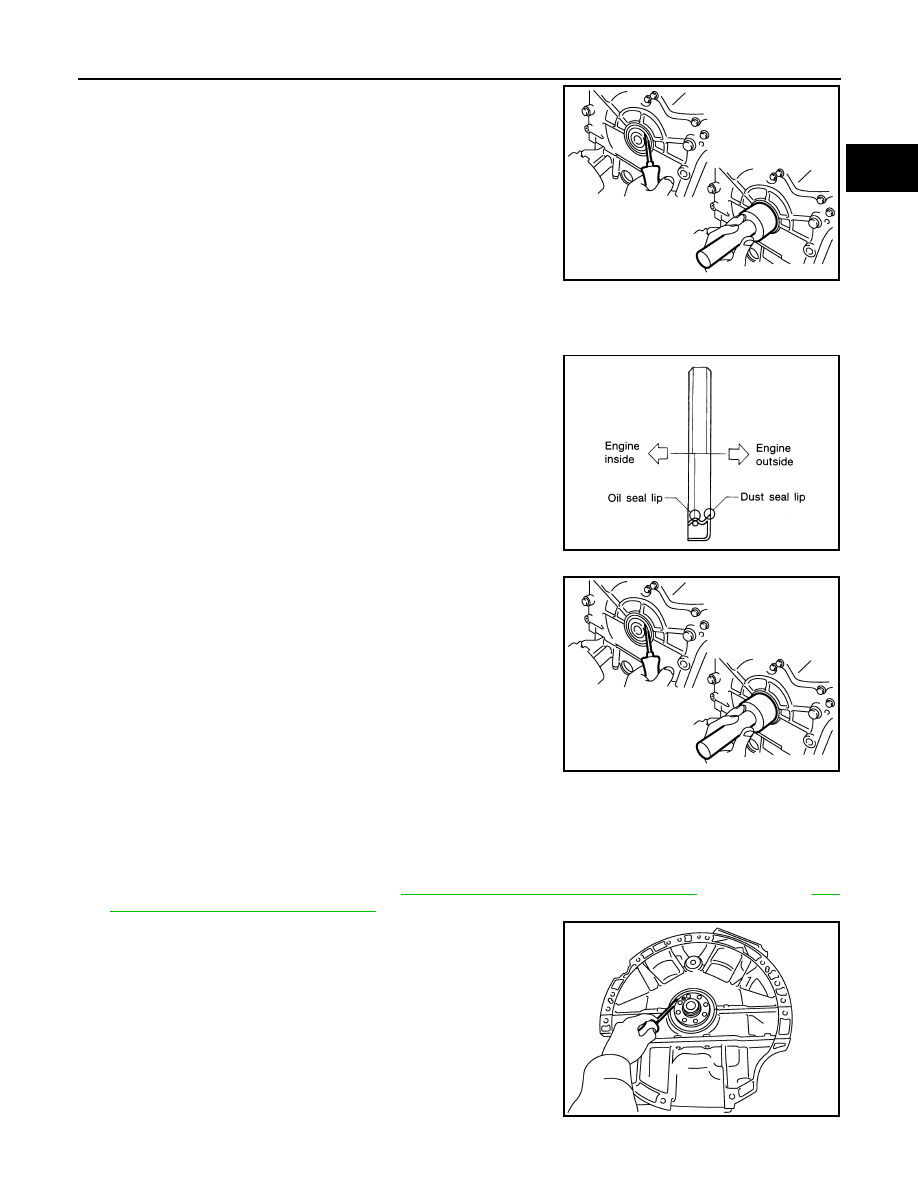

Remove front oil seal using suitable tool.

CAUTION:

Be careful not to damage front timing chain case and crank-

shaft.

INSTALLATION

1.

Apply new engine oil to both oil seal lip and dust seal lip of new front oil seal.

2.

Install front oil seal.

• Install front oil seal so that each seal lip is oriented as shown.

• Press-fit until the height of front oil seal is level with the mount-

ing surface using suitable tool.

- Suitable drift: outer diameter 60 mm (2.36 in), inner diameter

50 mm (1.97 in).

CAUTION:

• Be careful not to damage front timing chain case and

crankshaft.

• Press-fit straight and avoid causing burrs or tilting oil

seal.

3.

Installation is in the reverse order of removal after this step.

Removal and Installation of Rear Oil Seal

INFOID:0000000001281991

REMOVAL

1.

Remove transmission assembly. Refer to

TM-225, "2WD : Removal and Installation"

(2WD models),

228, "4WD : Removal and Installation"

2.

Remove rear oil seal with a suitable tool.

CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION

PBIC2931E

SEM715A

PBIC2931E

PBIC2932E