Nissan Pathfinder (2008 year). Manual - part 365

CAMSHAFT

EM-83

< ON-VEHICLE REPAIR >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

7.

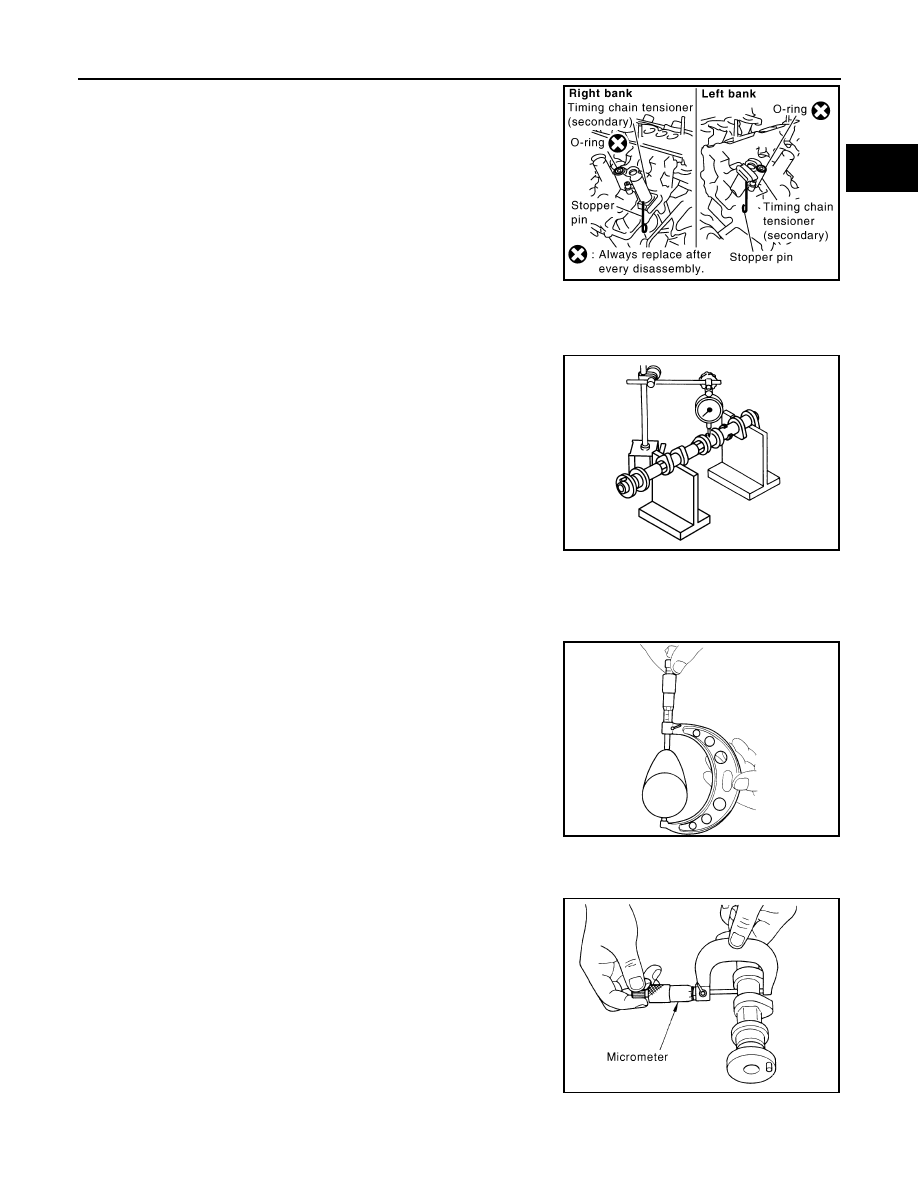

Remove timing chain tensioner (secondary) from cylinder head.

• Remove timing chain tensioner (secondary) with its stopper

pin attached.

NOTE:

Stopper pin was attached when timing chain (secondary) was

removed.

INSPECTION AFTER REMOVAL

Camshaft Runout

1.

Put V-block on precise flat table, and support No. 2 and 4 journal

of camshaft.

CAUTION:

Do not support journal No. 1 (on the side of camshaft

sprocket) because it has a different diameter from the other

three locations.

2.

Set dial indicator vertically to No. 3 journal.

3.

Turn camshaft to one direction with hands, and measure the

camshaft runout on dial indicator. (Total indicator reading)

4.

If it exceeds the limit, replace camshaft.

Camshaft Cam Height

1.

Measure the camshaft cam height with micrometer.

2.

If wear exceeds the limit, replace camshaft.

Camshaft Journal Oil Clearance

CAMSHAFT JOURNAL DIAMETER

• Measure the outer diameter of camshaft journal with micrometer.

CAMSHAFT BRACKET INNER DIAMETER

• Tighten camshaft bracket bolt with the specified torque.

PBIC2111E

Standard

: Less than 0.02 mm (0.0008 in)

Limit

: 0.05 mm (0.0020 in)

PBIC0929E

Standard:

Intake

: 45.465 - 45.655 mm (1.7900 - 1.7974 in)

Exhaust

: 45.075 - 45.265 mm (1.7746 - 1.7821 in)

Limit:

Intake

: 45.265 mm (1.7821 in)

Exhaust

: 44.875 mm (1.7667 in)

EMQ0072D

Standard:

No. 1

: 25.935 - 25.955 mm (1.0211 - 1.0218 in)

No. 2, 3, 4

: 23.445 - 23.465 mm (0.9230 - 0.9238 in)

PBIC0040E