Nissan Pathfinder (2008 year). Manual - part 324

P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

EC-709

< COMPONENT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

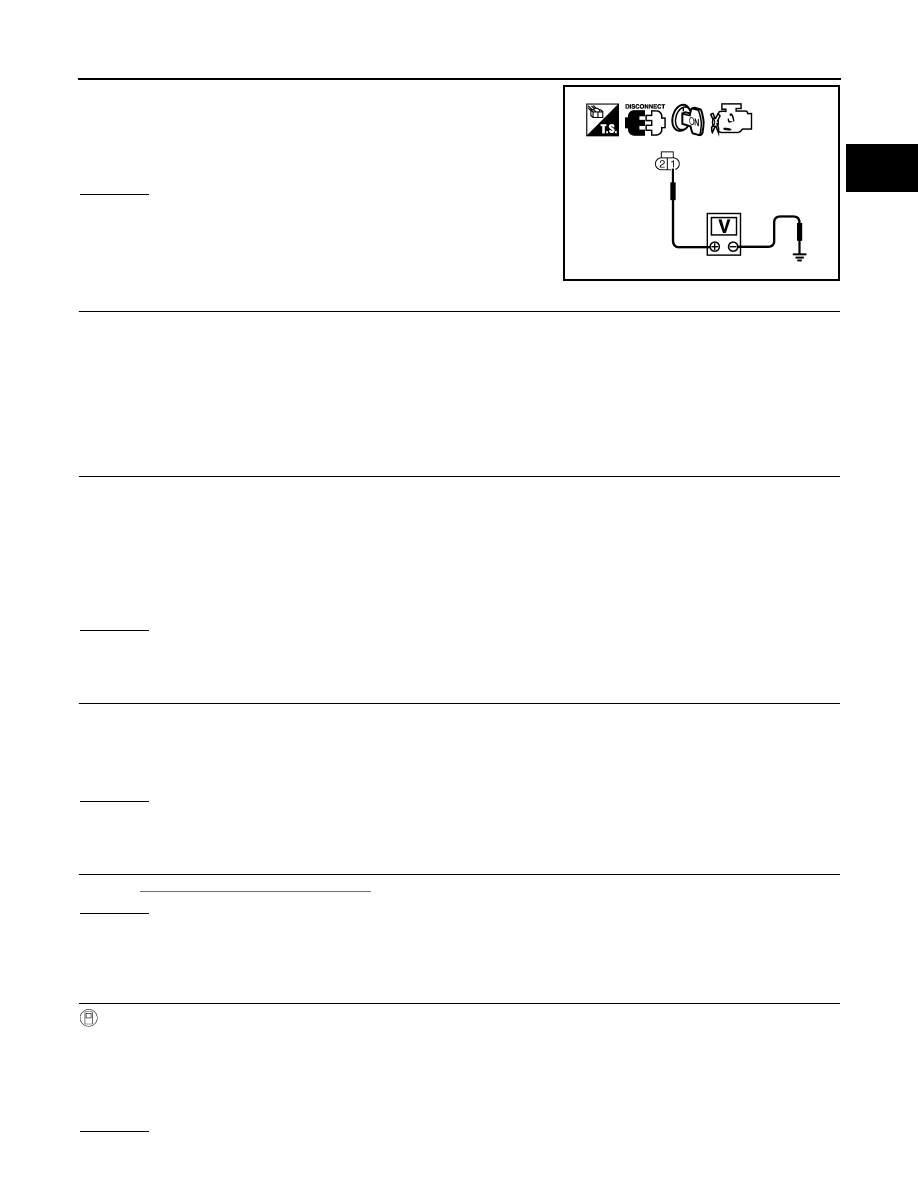

4.

Check voltage between EVAP canister purge volume control

solenoid valve terminal 1 and ground with CONSULT-III or

tester.

OK or NG

OK

>> GO TO 3.

NG

>> GO TO 2.

2.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between EVAP canister purge volume control solenoid valve and IPDM E/R

• Harness for open or short between EVAP canister purge volume control solenoid valve and ECM

>> Repair harness or connectors.

3.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check harness continuity between ECM terminal 45 and EVAP canister purge volume control solenoid

valve terminal 2. Refer to Wiring Diagram.

4.

Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 4.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1.

Disconnect EVAP control system pressure sensor harness connector.

2.

Check connectors for water.

OK or NG

OK

>> GO TO 5.

NG

>> Replace EVAP control system pressure sensor.

5.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-725, "Component Inspection"

OK or NG

OK (With CONSULT-III)>>GO TO 6.

OK (Without CONSULT-III)>>GO TO 7.

NG

>> Replace EVAP control system pressure sensor.

6.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-III

1.

Turn ignition switch OFF.

2.

Reconnect all harness connectors disconnected.

3.

Start engine.

4.

Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT-III.

5.

Check that engine speed varies according to the valve opening.

OK or NG

Voltage: Battery voltage

PBIB2245E

Continuity should exist.

Water should not exist.