Nissan Pathfinder (2008 year). Manual - part 226

DLN-392

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: M205]

FRONT FINAL DRIVE

4.

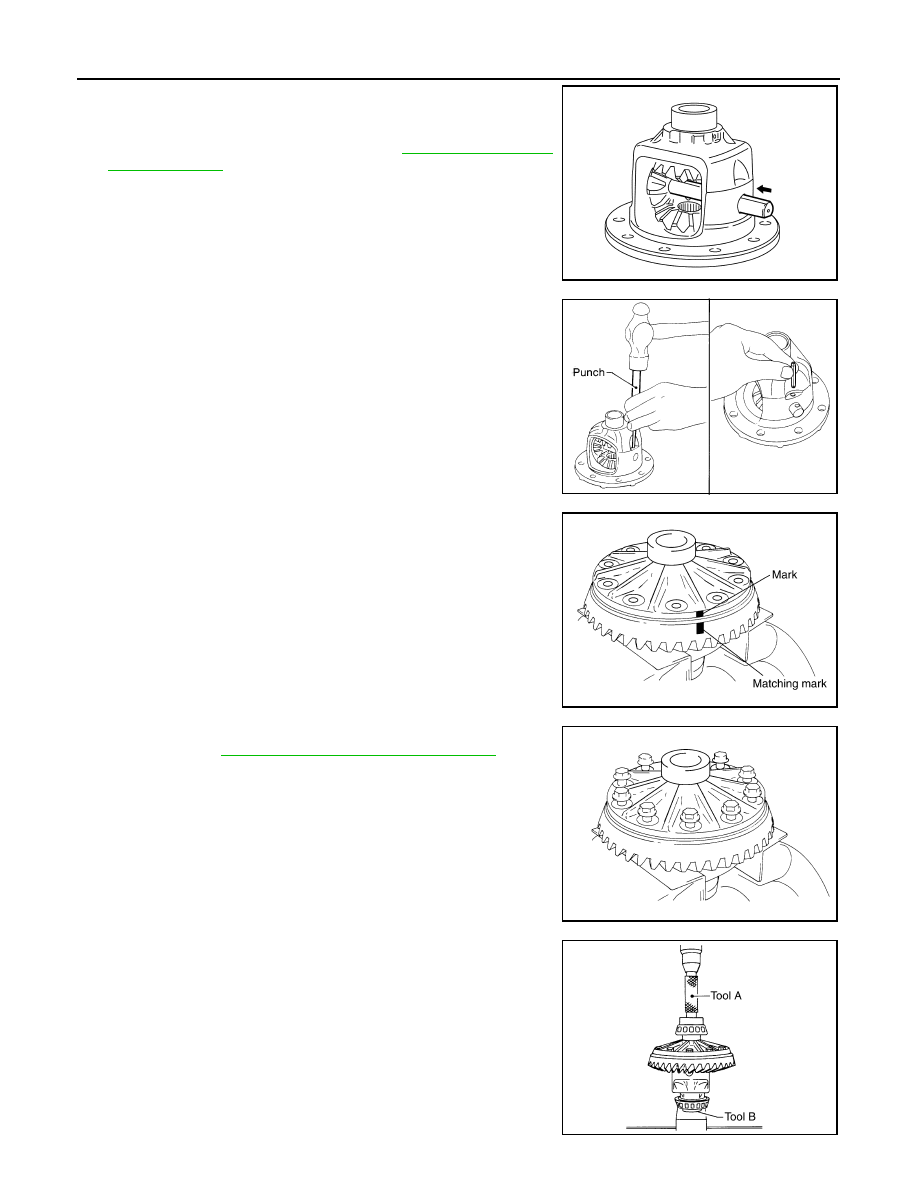

Install the pinion mate shaft and align the lock pin hole on the

pinion mate shaft with the lock pin hole on the differential case.

5.

Measure the side gear end play. If necessary, select the appro-

priate side gear thrust washers. Refer to

6.

Drive a new lock pin into the pinion mate shaft until it is flush

with the differential case using suitable tool.

CAUTION:

Do not reuse lock pin.

7.

Align the matching mark of the differential case with the mark of

the drive gear, then place the drive gear onto the differential

case.

8.

Install and tighten the new drive gear bolts to the specified

torque. Refer to

DLN-345, "Disassembly and Assembly"

.

CAUTION:

• Make sure the drive gear back and threaded holes are

clean.

• Do not reuse drive gear bolts.

• Tighten new drive gear bolts in a crisscross pattern.

9.

Press the new side bearing inner races to the differential case

using Tools.

CAUTION:

Do not reuse side bearing inner races.

SDIA0195J

SPD030

SDIA2593E

SDIA2239E

Tool number

A: KV38100300 (J-25523)

B: ST33081000

SPD353