Nissan Pathfinder (2008 year). Manual - part 224

DLN-376

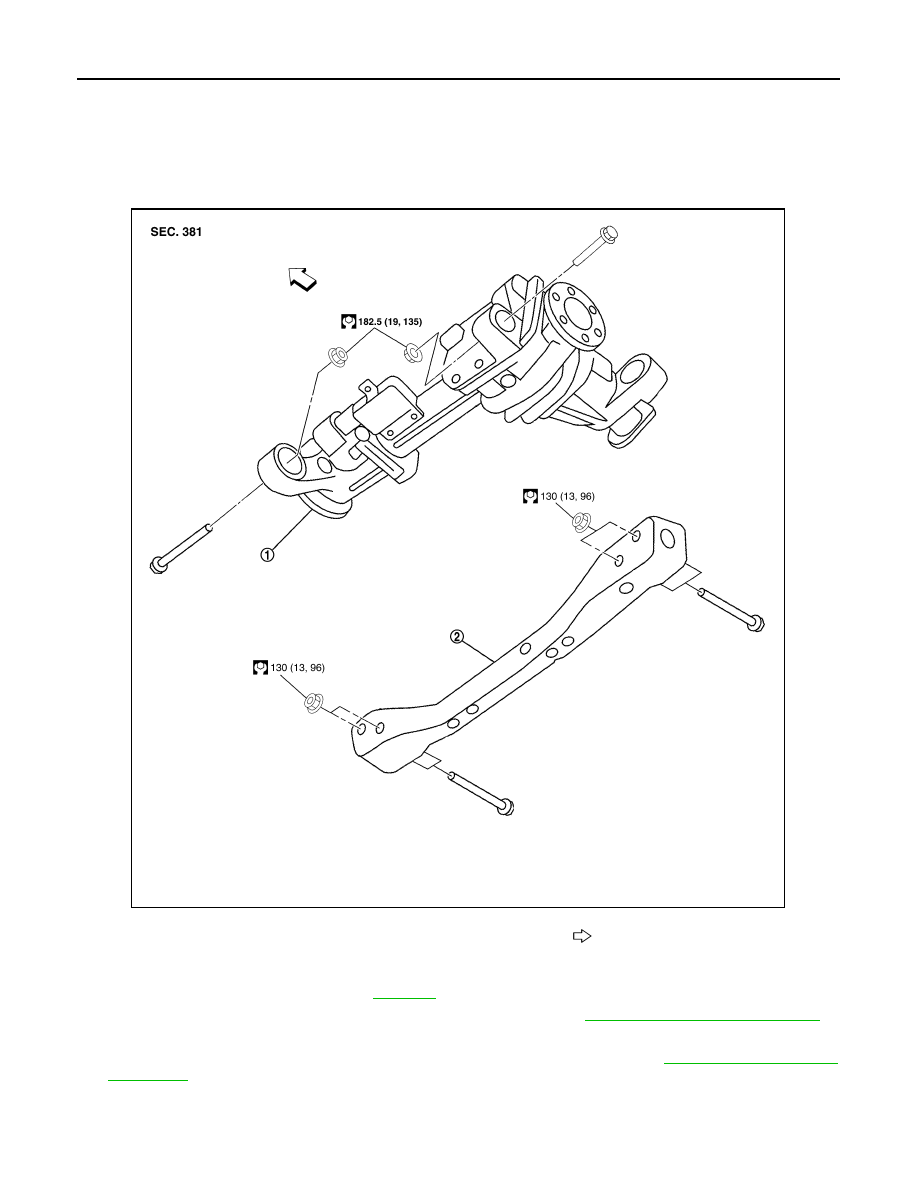

< REMOVAL AND INSTALLATION >

[FRONT FINAL DRIVE: M205]

FRONT FINAL DRIVE

REMOVAL AND INSTALLATION

FRONT FINAL DRIVE

Removal and Installation

INFOID:0000000001315891

REMOVAL

1.

Drain the differential gear oil. Refer to

2.

Remove the drive shafts from the front final drive assembly. Refer to

FAX-6, "Removal and Installation"

3.

Remove the front cross member.

4.

Remove the front propeller shaft from the front final drive assembly. Refer to

.

5.

Disconnect the vent hose from the front final drive assembly.

6.

Support the front final drive assembly using a suitable jack.

1.

Front final drive assembly

2.

Front cross member

Front

AWDIA0019GB