Nissan Pathfinder (2008 year). Manual - part 215

DLN-304

< SERVICE DATA AND SPECIFICATIONS (SDS)

[TRANSFER: TX15B]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

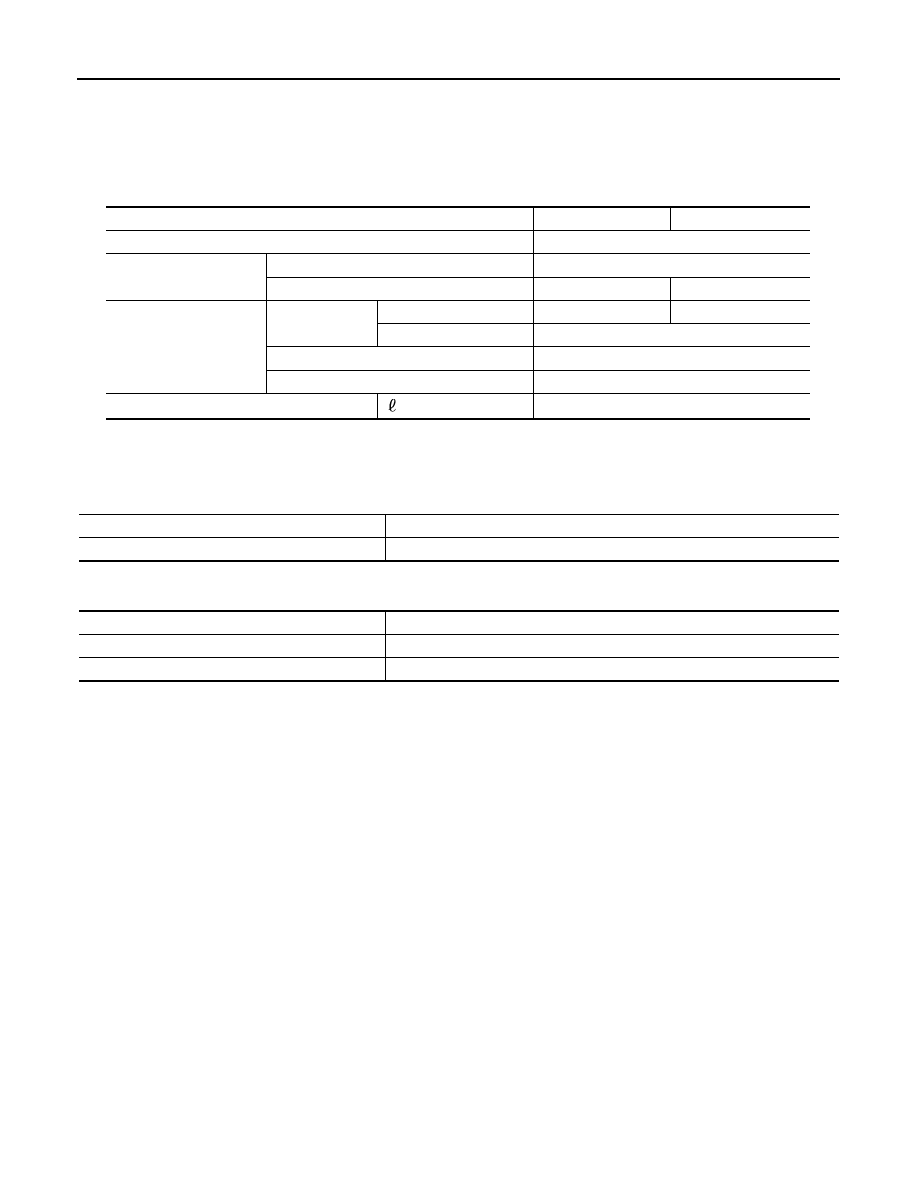

General Specification

INFOID:0000000001282325

Inspection and Adjustment

INFOID:0000000001282326

PINION GEAR END PLAY

Unit: mm (in)

CLEARANCE BETWEEN SHIFT FORK AND SLEEVE

Unit: mm (in)

Applied model

VQ40DE

VK56DE

Transfer model

TX15B

Gear ratio

High

1.000

Low

2.625

2.596

Number of teeth

Planetary gear

Sun gear

56

57

Internal gear

91

Front drive sprocket

38

Front drive shaft

38

Fluid Capacity (Approx)

(US qt, Imp qt)

2.0 (2 1/8, 1 3/4)

Item

Standard

Pinion gear end play

0.1 - 0.7 (0.004 - 0.028)

Item

Standard

2-4 shift fork to 2-4 sleeve

Less than 0.46 (0.018)

L-H shift fork to L-H sleeve

Less than 0.46 (0.018)