Nissan Pathfinder (2007 year). Manual - part 31

A/T SHIFT LOCK SYSTEM

AT-219

D

E

F

G

H

I

J

K

L

M

A

B

AT

2007 Pathfinder

Diagnostic Procedure

ECS00ELQ

SYMPTOM 1:

●

Selector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

●

Selector lever can be moved from “P” position with key in ON position and brake pedal released.

●

Selector lever can be moved from “P” position when key is removed from key cylinder.

SYMPTOM 2:

●

Ignition key cannot be removed when selector lever is set to “P” position.

●

Ignition key can be removed when selector lever is set to any position except “P”.

1.

CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK

>> GO TO 2.

NG

>> Repair key interlock cable. Refer to

2.

CHECK SELECTOR LEVER POSITION

Check selector lever position for damage. Refer to

AT-216, "Checking of A/T Position"

.

OK or NG

OK

>> GO TO 3.

NG

>> Check selector lever. Refer to

AT-216, "Adjustment of A/T Position"

.

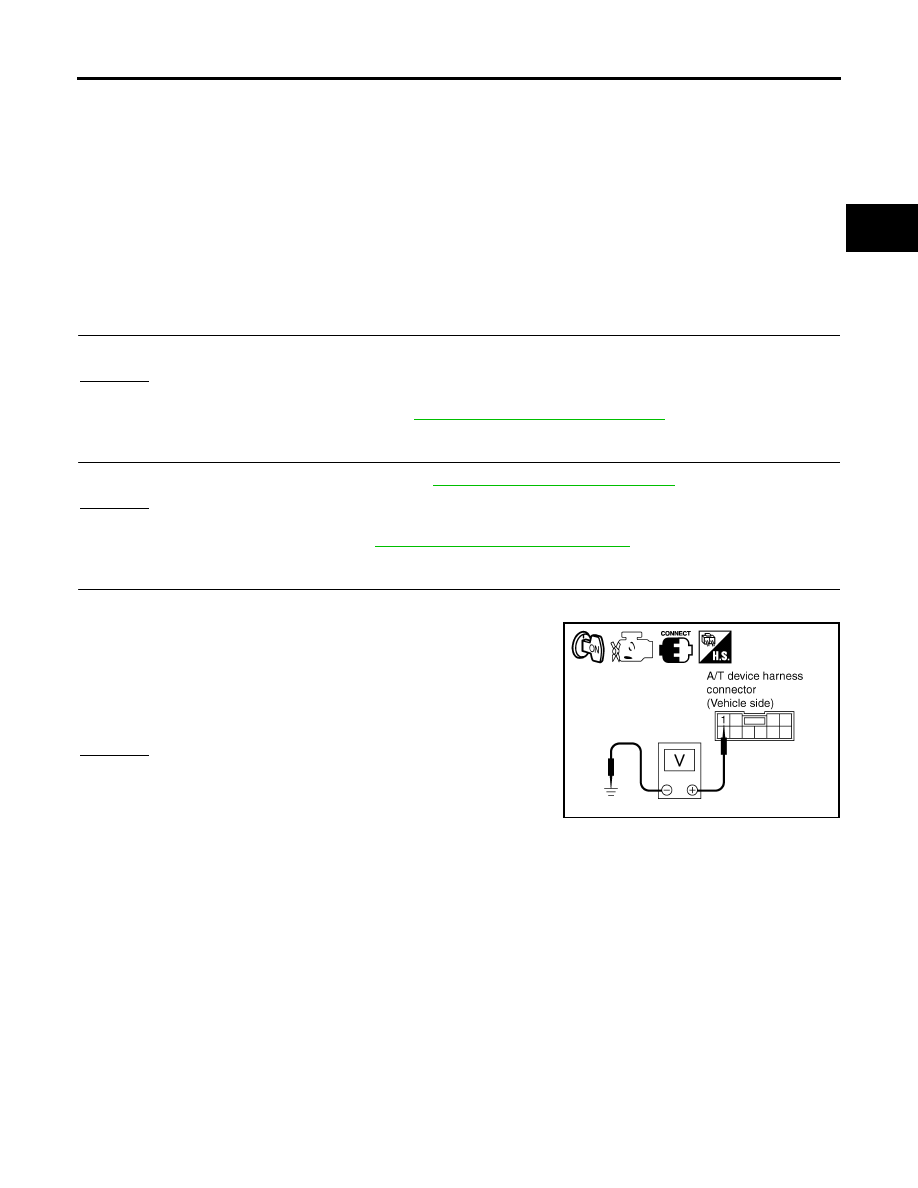

3.

CHECK INPUT SIGNAL A/T DEVICE

1.

Turn ignition switch “ON”.

2.

Check voltage between A/T device harness connector M156 ter-

minal 1 and ground.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

Voltage

Depressed brake pedal

:Battery voltage

Released brake pedal

:Approx. 0V

SCIA2122E