Nissan Pathfinder. Manual - part 533

EC-438

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

IGNITION SIGNAL

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair or replace harness or connectors.

7.

CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check the continuity between ignition coil harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair open circuit or short to power in harness or connectors.

8.

CHECK IGNITION COIL OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check the continuity between ignition coil harness connector and ECM harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair open circuit, short to ground or short to power in harness or connectors.

9.

CHECK IGNITION COIL WITH POWER TRANSISTOR

Check ignition coil with power transistor. Refer to

EC-440, "Component Inspection (Ignition Coil with Power

.

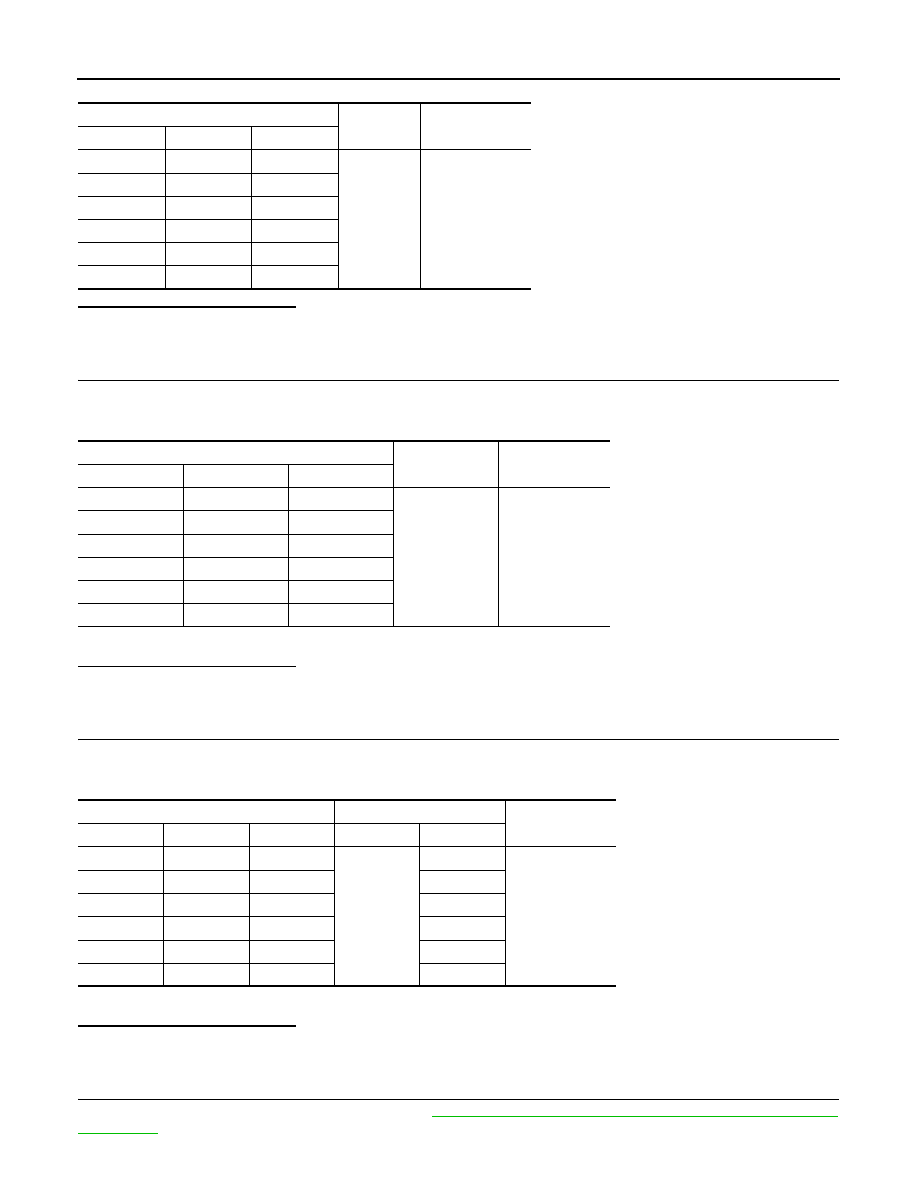

Ignition coil

Ground

Voltage

Cylinder

Connector

Terminal

1

F47

3

Ground

Battery voltage

2

F8

3

3

F48

3

4

F9

3

5

F49

3

6

F10

3

Ignition coil

Ground

Continuity

Cylinder

Connector

Terminal

1

F47

2

Ground

Existed

2

F8

2

3

F48

2

4

F9

2

5

F49

2

6

F10

2

Ignition coil

ECM

Continuity

Cylinder

Connector

Terminal

Connector

Terminal

1

F47

1

F51

11

Existed

2

F8

1

10

3

F48

1

9

4

F9

1

15

5

F49

1

14

6

F10

1

13