Nissan Pathfinder. Manual - part 429

EC-22

< SYSTEM DESCRIPTION >

[VQ35DE]

COMPONENT PARTS

In the driving range, ECM turns ON the electronically-controlled engine mount control solenoid valve and cuts

manifold pressure applied on the electronically-controlled engine mount. This increases damping force of the

electronically-controlled engine mount and reduces vibrations generated during driving.

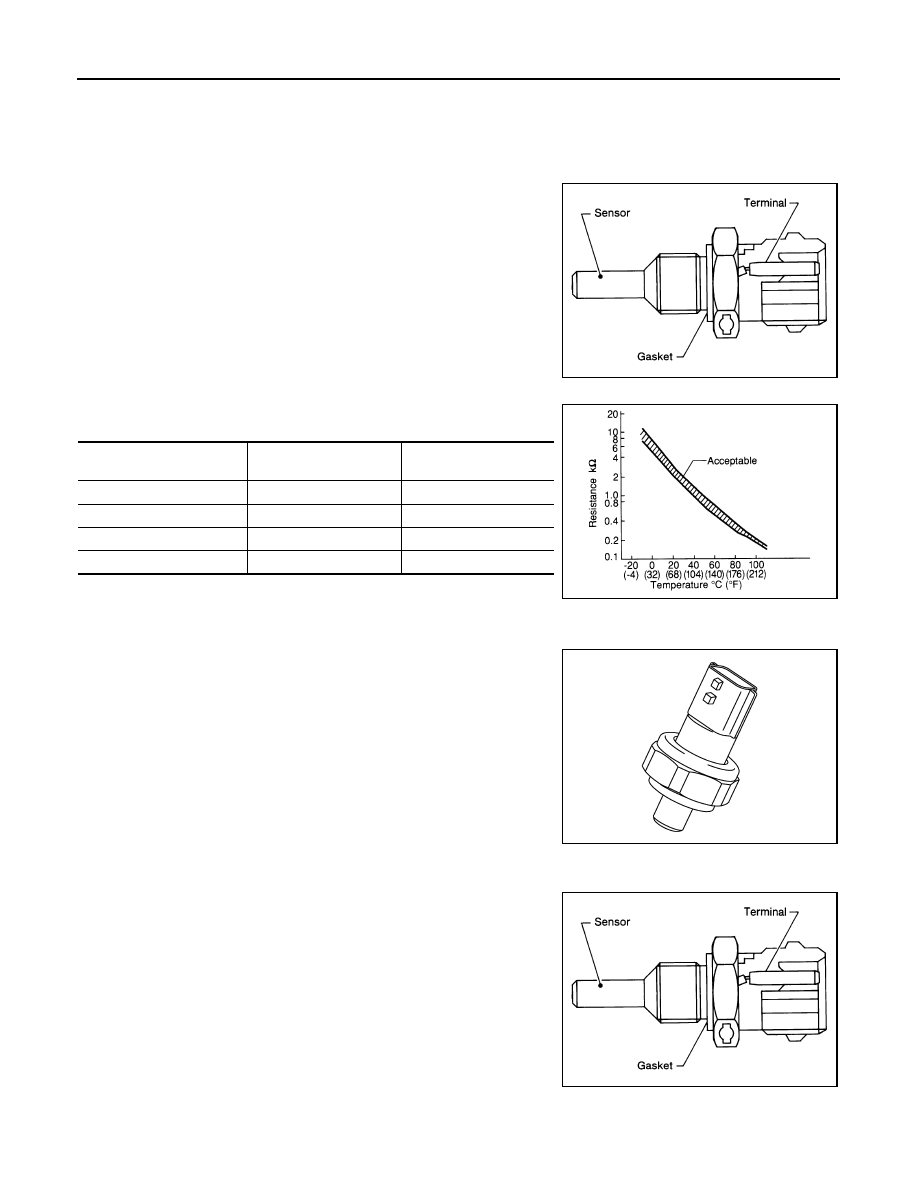

Engine Coolant Temperature Sensor

INFOID:0000000009178013

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine coolant

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Engine Oil Pressure Sensor

INFOID:0000000009178014

The engine oil pressure (EOP) sensor is detects engine oil pressure

and transmits a voltage signal to the ECM.

Engine Oil Temperature Sensor

INFOID:0000000009178015

The engine oil temperature sensor is used to detect the engine oil

temperature. The sensor modifies a voltage signal from the ECM.

The modified signal returns to the ECM as the engine oil tempera-

ture input. The sensor uses a thermistor which is sensitive to the

change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

SEF594K

Engine coolant temperature

[

°C (°F)]

Voltage

*

(V)

Resistance (k

Ω)

–10 (14)

4.4

7.0 - 11.4

20 (68)

3.5

2.37 - 2.63

50 (122)

2.2

0.68 - 1.00

90 (194)

0.9

0.236 - 0.260

SEF012P

JSBIA0292ZZ

SEF594K