Content .. 1184 1185 1186 1187 ..

Nissan Pathfinder. Manual - part 1186

OUTPUT SPEED SENSOR

TM-203

< REMOVAL AND INSTALLATION >

[CVT: RE0F10E]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

OUTPUT SPEED SENSOR

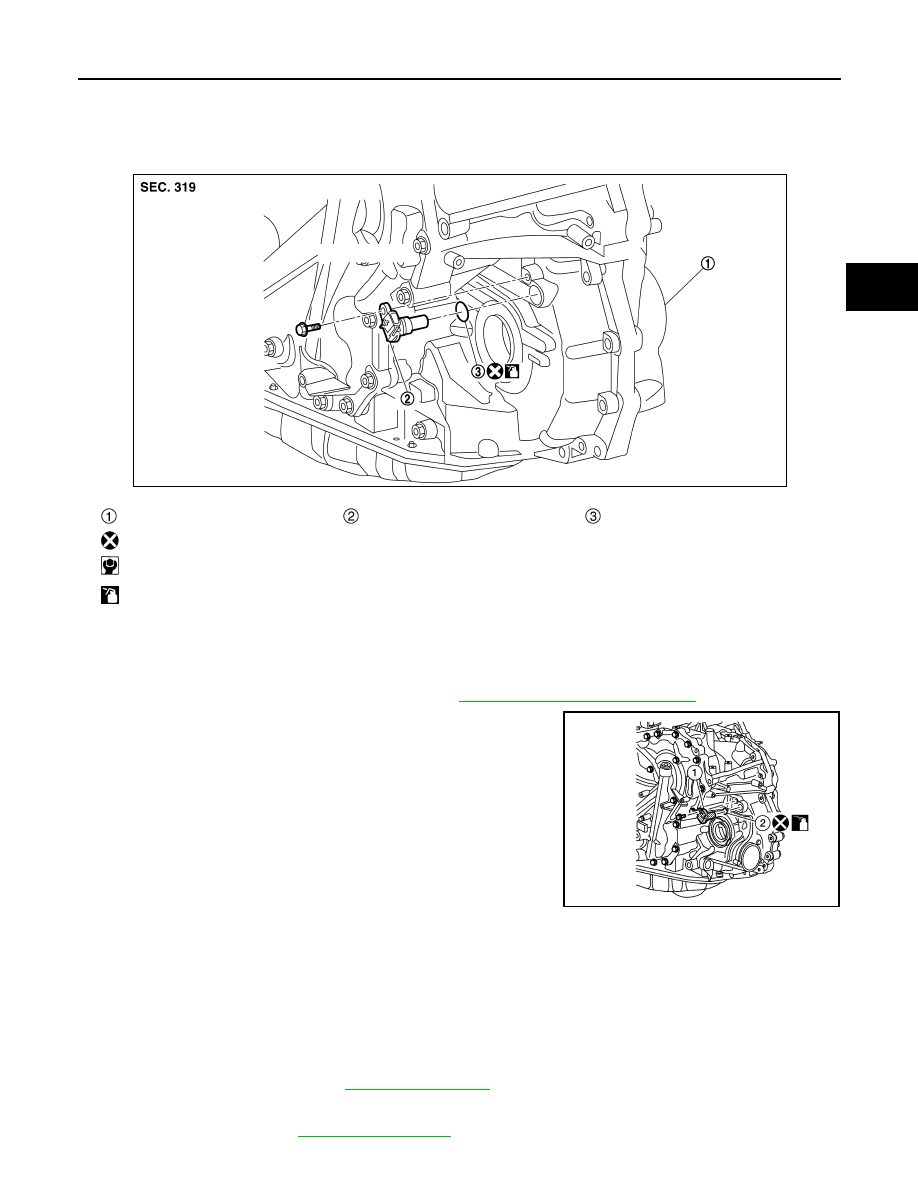

Exploded View

INFOID:0000000009177666

Removal and Installation

INFOID:0000000009177667

REMOVAL

1. Disconnect the battery negative terminal. Refer to

PG-90, "Removal and Installation"

2. Disconnect the harness connector from output speed sensor (1).

3. Remove the output speed sensor bolt, then the output speed

sensor (1).

4. Remove the O-ring (2) from the output speed sensor (1).

CAUTION:

Do not reuse O-ring.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-ring.

• Apply Genuine NISSAN CVT Fluid NS-3 to the O-ring.

Inspection and Adjustment

INFOID:0000000009177668

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to

.

ADJUSTMENT AFTER INSTALLATION

Adjust CVT fluid level. Refer to

Transaxle assembly

Output speed sensor

O-ring

: Always replace after every disassembly.

: N·m (kg-m, in-lb)

: Apply CVT fluid

JSDIA3727GB

ALDIA0363ZZ