Content .. 1155 1156 1157 1158 ..

Nissan Pathfinder. Manual - part 1157

STALL TEST

TM-87

< BASIC INSPECTION >

[CVT: RE0F10E]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

STALL TEST

Work Procedure

INFOID:0000000009177535

INSPECTION

1. Check the engine oil level. Replenish if necessary. Refer to

2. Check for leak of the CVT fluid. Refer to

.

3. Drive for about 10 minutes to warm up the vehicle so that the CVT fluid temperature is 50 to 80

°C (122 to

176

°F).

4. Be sure to apply the parking brake and block the tires.

5. Start the engine, depress the brake pedal and shift the selector lever to “D” position.

6. While depressing the brake pedal, depress the accelerator pedal gradually.

7. Read the stall speed quickly and release your foot from the accelerator pedal quickly.

CAUTION:

Do not depress the accelerator pedal for 5 seconds or more during the test.

8. Shift the selector lever to “N” position.

9. Cool the CVT fluid.

CAUTION:

Run the engine with the idle speed for at least 1 minute.

10. Put the selector lever to the R position and perform Step 6 to Step 9 again.

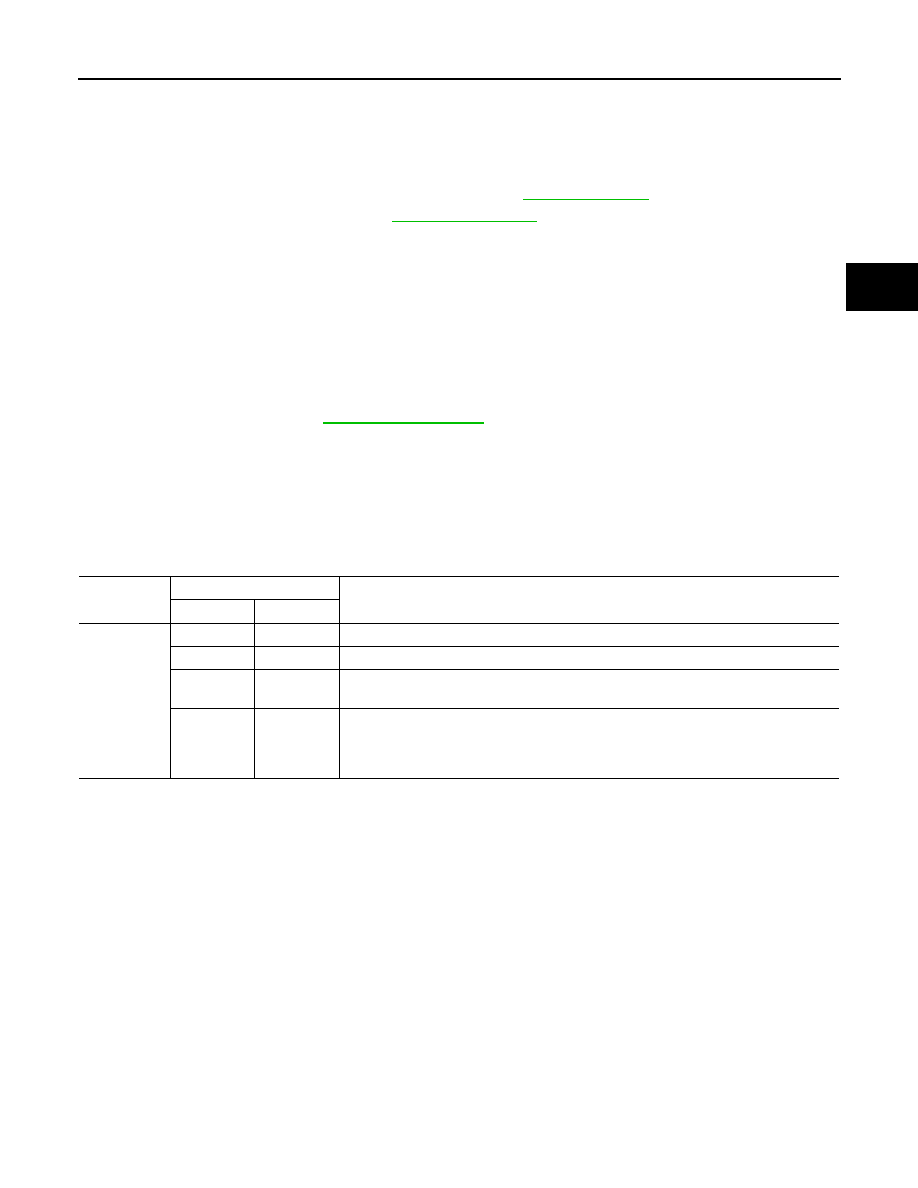

NARROWING-DOWN MALFUNCTIONING PARTS

O: Within the stall speed standard value.

H: Stall speed is higher than the standard value.

L: Stall speed is lower than the standard value.

Stall speed

: Refer to

.

Selector lever position

Possible cause

D

R

Stall speed

H

O

• Forward clutch

O

H

• Reverse brake

L

L

• Engine

• Torque converter one way clutch

H

H

• Line pressure is low.

• Primary pulley

• Secondary pulley

• Chain belt