Content .. 1137 1138 1139 1140 ..

Nissan Pathfinder. Manual - part 1139

COMPONENT PARTS

TM-15

< SYSTEM DESCRIPTION >

[CVT: RE0F10E]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

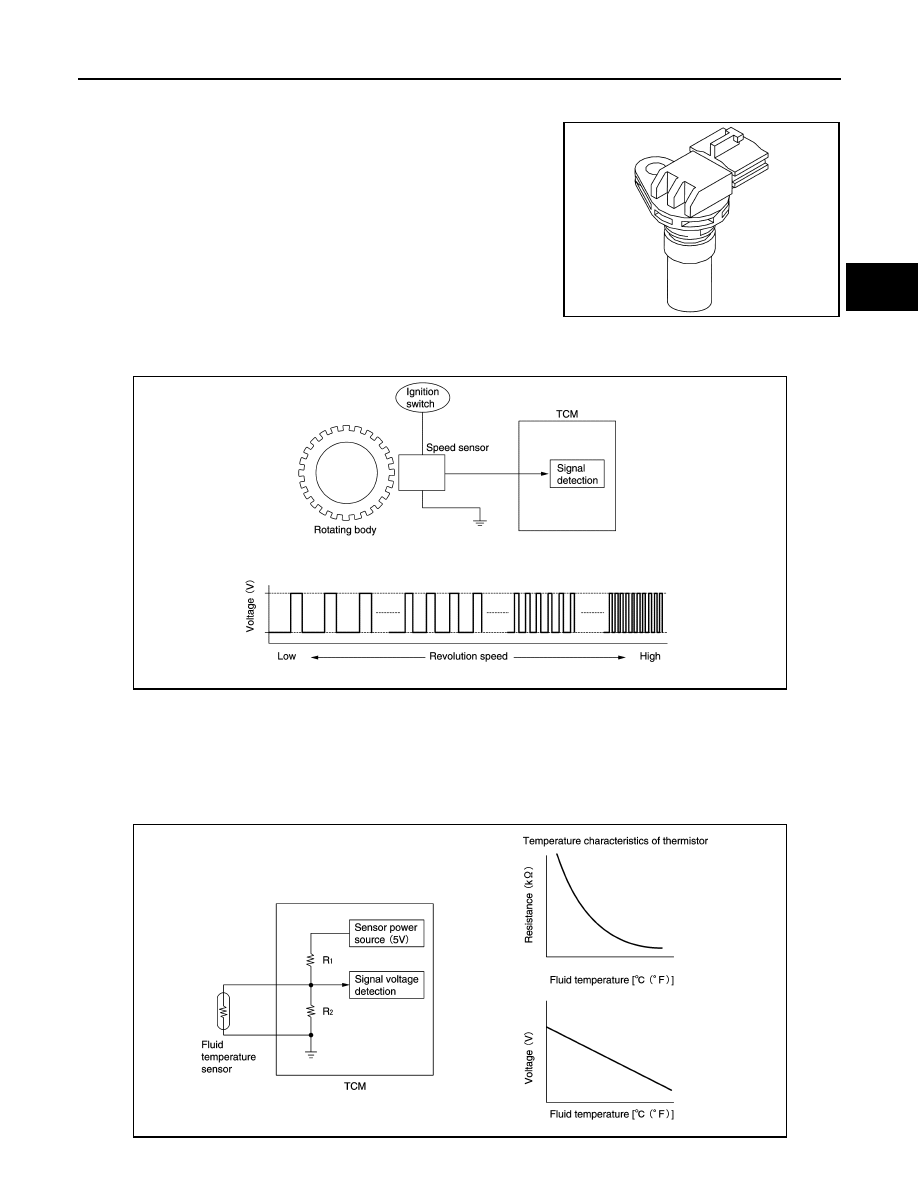

CVT CONTROL SYSTEM : Output Speed Sensor

INFOID:0000000009177482

• The output speed sensor is installed to the back side of transaxle

case.

• The output speed sensor detects final gear speed.

•

• The output speed sensor generates an ON-OFF pulse signal according to the rotating body speed. TCM

judges the rotating body speed from the pulse signal.

CVT CONTROL SYSTEM : CVT Fluid Temperature Sensor

INFOID:0000000009177483

• The CVT fluid temperature sensor is installed to control valve.

• The CVT fluid temperature sensor detects CVT fluid temperature in oil pan.

• The fluid temperature sensor uses a thermistor, and changes the signal voltage by converting changes in the

CVT fluid temperature to a resistance value. TCM evaluates the CVT fluid temperature from the signal volt-

age value.

JSDIA3073ZZ

JSDIA1824GB

JSDIA1825GB