Nissan Murano Z50 (2005 year). Manual - part 175

CAN SYSTEM (TYPE 10)

LAN-413

[CAN]

C

D

E

F

G

H

I

J

L

M

A

B

LAN

Revision: 2005 August

2005 Murano

2.

CHECK HARNESS FOR OPEN CIRCUIT

1.

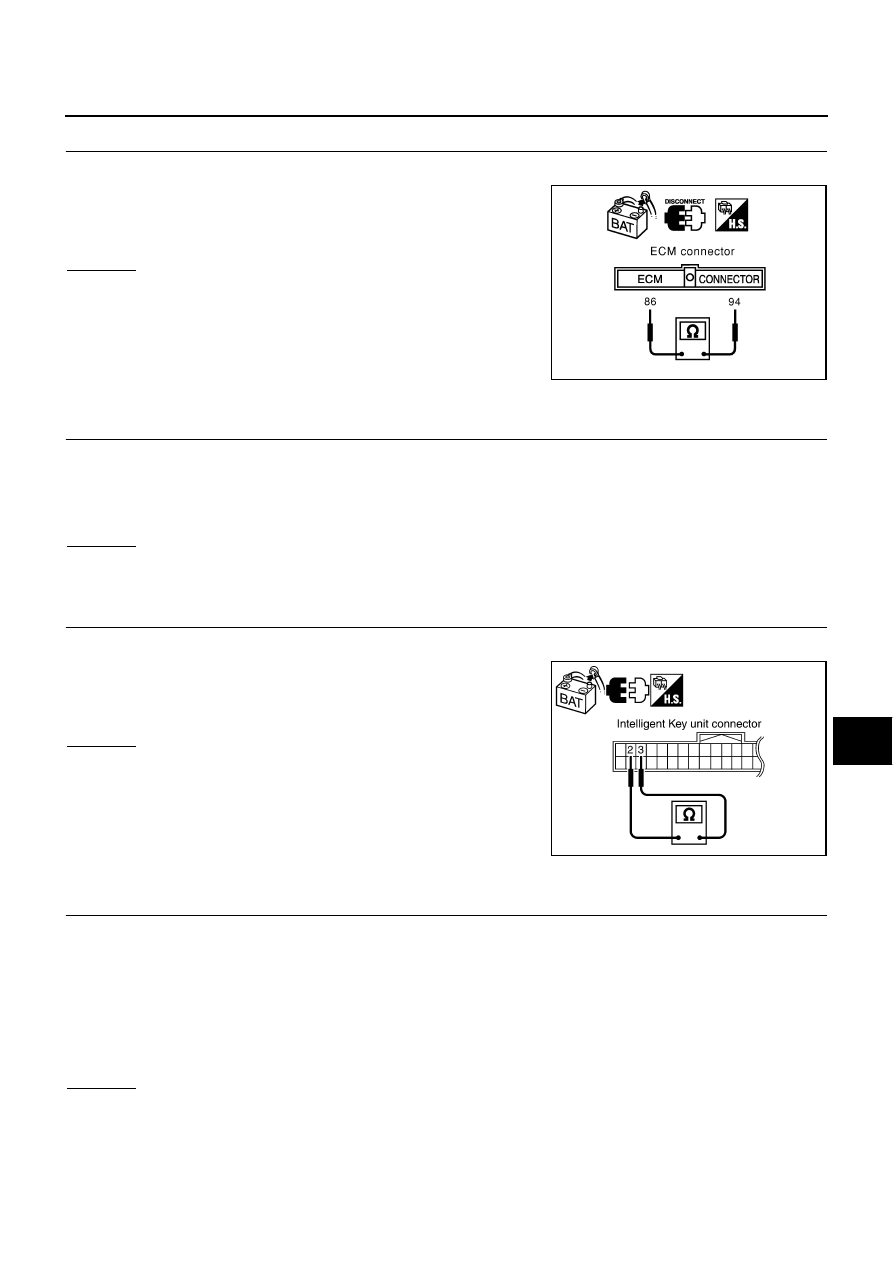

Disconnect ECM connector.

2.

Check resistance between ECM harness connector M80 termi-

nals 94 (L) and 86 (Y).

OK or NG

OK

>> Replace ECM.

NG

>> Repair harness between ECM and BCM.

Intelligent Key Unit Circuit Inspection

AKS00CHZ

1.

CHECK CONNECTOR

1.

Turn ignition switch OFF.

2.

Disconnect the battery cable from the negative terminal.

3.

Check terminals and connector of Intelligent Key unit for damage, bend and loose connection (control

module side and harness side).

OK or NG

OK

>> GO TO 2.

NG

>> Repair terminal or connector.

2.

CHECK HARNESS FOR OPEN CIRCUIT

1.

Disconnect Intelligent Key unit connector.

2.

Check resistance between Intelligent Key unit harness connec-

tor M99 terminals 2 (L) and 3 (Y).

OK or NG

OK

>> Replace Intelligent Key unit.

NG

>> Repair harness between Intelligent Key unit and BCM.

TCM Circuit Inspection

AKS00CI0

1.

CHECK CONNECTOR

1.

Turn ignition switch OFF.

2.

Disconnect the battery cable from the negative terminal.

3.

Check following terminals and connectors for damage, bend and loose connection (control module side

and harness side).

–

TCM connector

–

Harness connector F102

–

Harness connector M82

OK or NG

OK

>> GO TO 2.

NG

>> Repair terminal or connector.

94 (L) - 86 (Y)

: Approx. 108 - 132

Ω

SKIA6865E

2 (L) - 3 (Y)

: Approx. 54 - 66

Ω

PKIB5312E