содержание .. 636 637 638 639 ..

Nissan Murano. Manual - part 638

EM-126

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

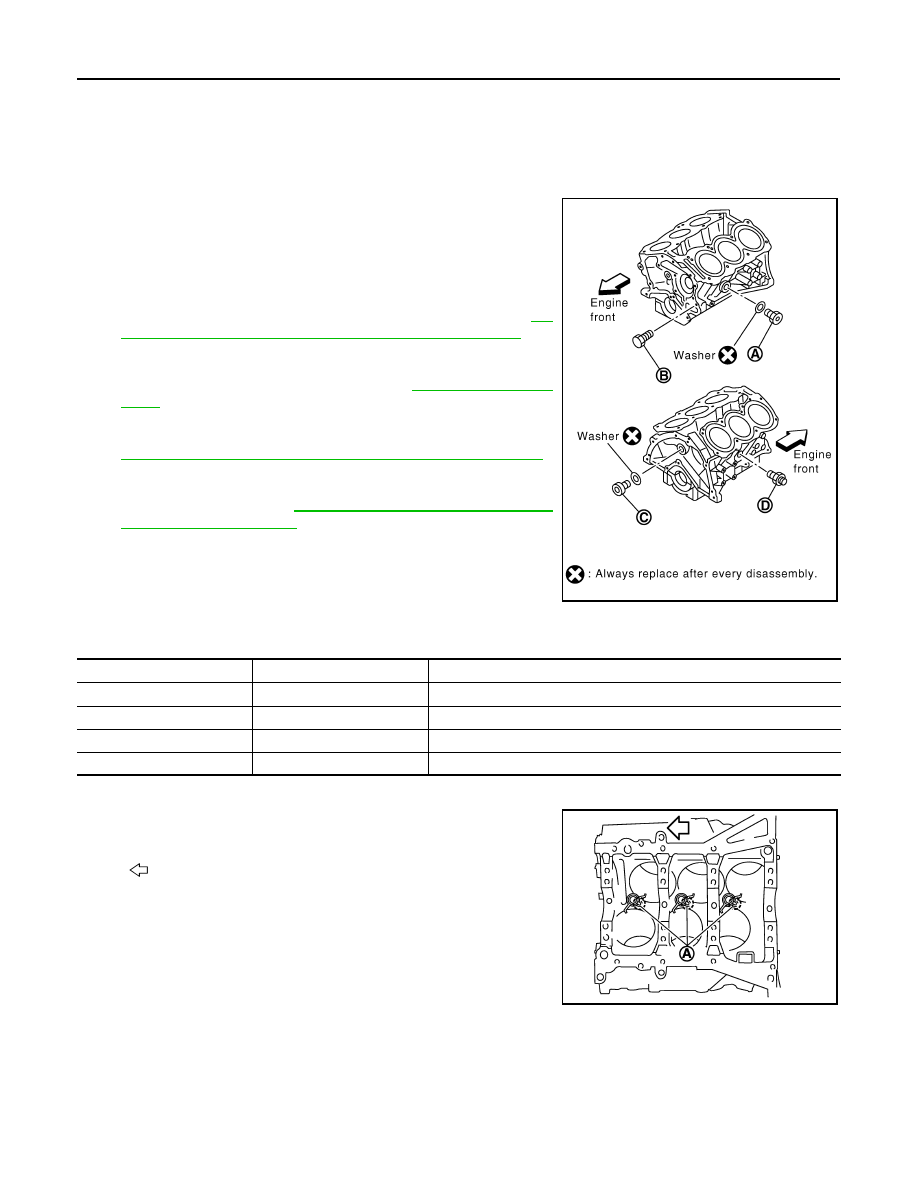

CAUTION:

Do not reuse washers.

1.

Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

CAUTION:

Use a goggles to protect your eye.

2.

Install each plug to cylinder block as shown in the figure.

CAUTION:

Do not reuse washers.

• Apply sealant to the thread of water drain plug (A).

Use Anaerobic Liquid Gasket or equivalent. Refer to

22, "Recommended Chemical Products and Sealants"

.

NOTE:

For Canada, water drain plug (A) in the figure is not water

drain plug but block heater. Refer to

.

• Apply sealant to the thread of connector bolt (D).

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

.

• Apply sealant to the thread of plug (C).

Use genuine high strength thread locking sealant or

equivalent. Refer to

• Replace washers with new one.

• Tighten each plug and connector bolt as specified below.

3.

Install oil jet.

• Insert oil jet dowel pin (A) into cylinder block dowel pin hole,

and tighten mounting bolts.

4.

Install main bearings and thrust bearings as follows:

CAUTION:

Be careful not to drop main bearing, and to scratch the surface.

a.

Remove dust, dirt, and engine oil on bearing mating surfaces of cylinder block and main bearing caps.

B

: Water drain plug

PBIC2487E

Part

Washer

Tightening torque

A

Yes

62.0 N·m (6.3 kg-m, 46 ft-lb)

B

No

9.8 N·m (1.0 kg-m, 87 in-lb)

C

Yes

62.0 N·m (6.3 kg-m, 46 ft-lb)

D

No

39.2 N·m (4.0 kg-m, 29 ft-lb)

: Engine front

JPBIA0198ZZ